SECURING SUSPENSION OF THE LOAD.

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

Another Effort to Isolate Live and Dead -Loads from Road Shocks.

TN A recent issue we described at some length two different types of' motor coach bodies in which special means had been introduced in Order to reduce the risk of road shocks being communicated through the chassis to the passengers. In one design, it will be recalled, each body bearer was. supported on two steel balls carried between hemispherical cups, thus permitting a small amount of movement between body and chassis, whilst in the ether design supplementary laminated springs disposed between chassis frame proper and a lighter frame, forming what might be termed the foundation for the body, were employed. Each idea had as its object the isolation of the body and its load from the effects of road shock, and another worthy contribution towards a solution of this pro. blem is to be found in the Holden suspension system.

This system differs fundamentally from other devices which have been invented to effect the same end, and that it has passed beyond the. experimental stage is indicated by the fact thata number of passenger-carrying vehicles on which it has been adopted are already being supplied, par-. ticuiarly in the case of the products which leave the works of one of the most prominent makers of commercial vehicles.

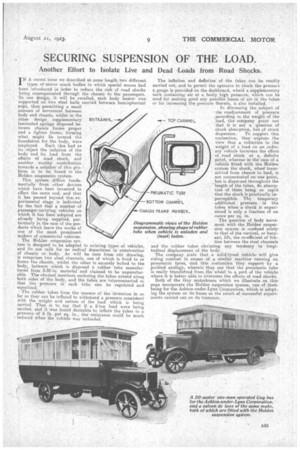

The Holden suspension system is designed to be adapted to existing types of vehicles, and its use calls for no radical departures in construction of chassis or body. As will be seen from our drawing, it comprises two steel channels, one of which is fixed to or forms the chassis, whilst the other is securely bolted to the body, between which is disposed a rubber tube manufactured home 3-32-in, material and claimed to be unpunctur. able. The channel members enclosing the tubes extend along both sides of the body, and the tubes are interconnected so that the pressure in each tube can be regulated and • equalized. The rubber tubes form the essence of the invention in so far as they can be inflated to withstand a pressure consistent with the weight and nature of the load which is being carried. That is to say that if a 2-ton load were being carried, and it was found desirable to inflate the tubes to a pressure of 5 lb. per sq. in., the resistance could be muck reduced when the vehicle was unloaded. RESTRAINER_ The inflation' and deflation of the tubes can be readily carried out, arid to permit the operator to check the pressure a gauge is provided on the dashboard, where a supplementary tank containing air at a fairly high pressure, which can be used for making good any possible losses of air in the tubes or for increasing the pressure therein, is also installed. In discussing the subject of the readjustment of pressure . according to the weight of the load, the company point out that it is not a question of shock absorption, but of shock dispersion.To support this contention, they express the view that a reduction in the weight of a load on an ordinary vehicle increases the effect ot road shock at a. definite point, whereas in the case of a vehicle fitted with the Holden system the shock, where transmilted from chassis to load, is not concentrated on one point, but is dispersed throughout the 'length of the tubes, its.absorption of them being so rapid that the shock is practically imperceptible. The temporary additional pressure in the tubes when a shock is experienced is only a fraction of an ounce per sq. in. The question of body movement with the Holden suspension system is confined solely to that of the vertical, or buoyant, lift, the co-efficient of Inc. tion between the steel channels and the rubber tubes obviating any tendency to longitudinal displacement of the body. The company state that a solid-tyred vehicle: will give riding comfort in excess of a similar machine running on pneumatic tyres, -and this contention they support by a pointed analogy, wherein they say that the pneumatic tube is really transfetred from the wheel to a part of the vehicle where it is better able to overcome the effects of road shocks.

Both of the Guy motorbuses which we illustrate on this page incorporate the Holden suspension system, one of them being for the Ashton-under-Lyne Corporation, which is adopting the system on its buses as the result ef successful experiments carried out on its tramcars. Diagrammatic views of the Holden suspension, showing shape of rubber tube when vehicle is unladen and (inset) laden.