CLAYTON )EWANDRE ACTI rITIES

Page 54

Page 55

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

Notes Made Inspection of t Processes, an( Progress whici at the Titanic

uring a Close Manufacturing Details of the 3 Being Made VOrks, Lincoln AVISIT to the Lincoln works of the Clayton Dewandre Co., Ltd., is a revelation of intense activity and rapid progress. The number of men now employed at the Titanic Works, Lincoln, is approximately 700, and, despite the low condition of many trades, extensions are constantly being made in every section to cope with the demand. Two shifts of eight hours each are being worked, and it is highly probable that the whole 24 hours will soon be occupied.

The leading articles which are being manufactured are the DeAwandre vacuum brake, Clayton axles, with or without Rubury brake gear, and Still tubes and radiators. In the commercial-vehicle spltere the Dewandre brake has made astonishing progress, and It is this device which has done so much to increase the braking efficiency of the latest-type London bus and which has bctn standardized on practically every other make of vehicle, so that it is now in a commanding position.

The designers are always busy in the endeavour to attain greater efficiency, and it is notable that the company's experts have been responsible for the majority of the braking layouts amongst commercial chassis. The vacuum brake is one of the greatest boons which have been conferred on the driver, for by reducing to something like one-third the energy required in brake application the driving fatigue has been diminished in a most commendable manner. Occasionally the old bogy is raised concerning the possible risk which may occur if an engine stops, thus throwing the servo brake out of action, but with a good layout the efficiency of a foot brake still remains at approximately 90 per cent, of that which it would be in the ordinary design not incorporating a vacuum servo. It must also be remembered that very few vehicles are now allowed to run with the gear lever in neutral, and providing that a gear is in mesh the engine, even if it be not firing, can always be turned by the clutch until the vehicle cV is actually stationary on the road.

Considerable progress is also being made in connection with Clayton front and back axles, and here again difficulties have been successfully overcome. For instance, on taxicabs the lock has to be 58 degrees, but front-wheel brakes have been designed to cope with such a severe angle, the operating mechanism incorporating a new patented form of universal joint, whilst for worm drives a new banjo type of back axle is on the stocks.

The Still tube is a real winner, and is so efficient that the number of tubes which would ordinarily be required in a radiator can be reduced by, roughly, twothirds. Despite this, the company is producing five to six miles of tube per week, which involve the employment of 1,200 miles of copper wire, the material used for the special fins. The Clayton Still wirewound-tube radiators are now extensively used, and have proved of marked advantage in tropical countries, where the maximum cooling is required in the available space.

Special designs have also been evolved in which the tubes are bent into a semi circular form with a blower fan disposed in the centre and radially discharging the air through the rows of tubes. Very satisfactory results have 'been obtained with these designs.

The main factors in efficient radiator design are cooling surface,' water and air flows. The correct balance of these three factors is important and is determined in the research laboratory and proved conclusively in practical use.

Apart from its use on radiators, the Still tube has proved to have such remarkable characteristics that it is now being used to an ,increasing extent in refrigerator work, whilst a still more novel application is for the feed-water heaters of boilers. Investigations are now being made into the possibility of using stacks, of these tubes as heating radiators for factories, etc., air being passed through them by means of fans. So effective is this system that a comparatively large workshop can be rapidly warmed by a Still-tube heater occupying a very small space.

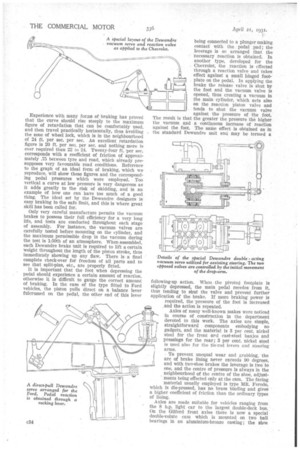

Reverting to the Dewandre brake, special types of very simple design have been produced for fitting to such vehicles as the Ford and Chevrolet. A type of servo has also been developed for assisting steering. In this case the piston is acted upon from either side and there are two opposed valves controlled by the initial movement of the drop arm. In developing the Dew andre vacuum brake the company has had to face many difficulties which might be considered outside its province. It has not been satisfied merely to apply a servo to brakes which are of inefficient design. It was found that, in many vehicles, axles could turn on their springs or actually go back slightly owing to shackles, whilst cross-shafts are particularly subject to torsion. The effect of braking with a vehicle in motion is totally different from the results obtained from holding a vehicle stationary and forcibly rotating the wheels against the brakes, unless the system be so designed that the proportion of power remains the same. A solution of the difficulty of torsional losses in cross-shafts, etc., is to employ two separate vacuum brake cylinders for the front brakes which draw their vacuum from the main unit utilized for the rear brakes, there being no mechanical connection with the front brakes, the only communication being by vacuum pipes; this gives a very satisfactory effect and obviates one of the causes of brake grab.

We raised the question of the slight lag which is bound to occur in the operation of a vacuum device. Tests have shown that this is insignificant. A driver who is suddenly asked to apply the brakes without previous warning can apply immediately slightly over .50 lb. on a pedal, but to exert a pressure of 200 lb. or more, as is frequently necessary with non-servo brakes, and to obtain this immediately, Is another matter; the driver would first have to take up a suitable position in his seat, the final result being that the average servo lag is less than the physical lag. Experience with many forms of braking has proved that the curve should rise steeply to the maximum figure of retardation that can be comfortably used, and then travel practically horizontally, thus avoiding the zone of wheel lock, which is in the neighbourhood of 24 ft. per sec. per sec. An excellent retardation figure is 20 ft. per sec, per sec, and nothing more is ever required than 22 to 24. Twenty-four ft. 'per sec. corresponds with a coefficient of friction of approximately .75 between tyre and road, which already presupposes very favourable road conditions. Reference to the graph of an ideal form of braking, which we reproduce, will show these figures and the corresponding pedal pressures which were employed. Too vertical a curve at low pressure is very dangerous as it adds greatly to the risk of skidding, and is an example of how one can have too much of a good thing. The ideal set by the Dewandre designers is easy braking to the safe limit, and this is where great skill has been called for.

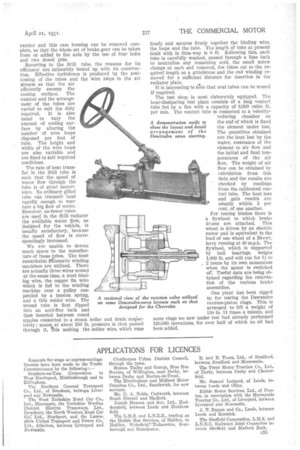

Only very careful manufacture permits the vacuum brakes to possess their full efficiency for a very long life, and tests are conducted throughout each stage of assembly. For instance, the vacuum valves are carefully tested before mounting on the cylinder, and the maximum permissible drop in the vacuum during the test is 1750th of an atmosphere. When assembled, each Dewandre brake unit is required to lift a certain weight throughout the length of the piston stroke, thus immediately showing up any flaw. There is a final complete check-over for freedom of all parts and to see that split-pins, etc., are properly fitted.

It is important that the foot when depressing the pedal should experience a certain amount of reaction. otherwise it is difficult to gauge the correct amount of braking. In the case of the type fitted to Ford vehicles, the piston pulls direct on a balance lever fulcrumed on the pedal, the other end of this lever being connected to a plunger making contact with the pedal pad; the leverage is so arranged that the necessary reaction is obtained. In another type, developed for the . Chevrolet, the reaction is effected through a reaction valve and takes effect against a small hinged footplate on the pedal. In applying the brake the release valve is shut by the foot and the vacuum valve is opened, thus creating a vacuum in the main cylinder, which acts also on the reaction piston valve and tends to shut the vacuum valve against the pressure of the foot. The result is that the greater the pressure the higher the vacuum and a continuous increase of reaction against the foot. The same effect is obtained as in the standard Dewandre unit and may be termed a following-up action. When the pivoted footplate is slightly depressed, the main pedal recedes from it, thus tending to shut the valve and prevent further application of the brake. If more braking power Is required, the pressure of the foot is increased and the action is repeated.

Axles of many well-known makes were noticed in course of construction in the department devoted to this work. The axles are simple, straightforward components embodying no gadgets, and the material is 3 per cent. nickel steel for the front ard cast-steel banjos and pressings for the rear; 3 per cent. nickel steel is used also for the tie-rod levers and steering arms.

To prevent unequal wear and grabbing, the arc of brake lining never exceeds 90 degrees, and with two-shoe brakes the leverage is two to one, and the centre of pressure is always in the neighbourhood of the centre of the shoe, adjust' ments being effected only at the cam. The facing material usually employed is type MR. Ferodo, which is die-pressed, has no brass binding and gives a higher coefficient of friction than the ordinary types of lining.

Axles are made suitable for vehicles ranging from the 8 h.p. light car to the largest double-deck bus. On the Gilford front axles there is now a special double-volute cam which is mounted on two ball bearings in an aluminium-bronze casting; the shoe carrier and this cam housing can be removed complete, so that the whole set of brake gear can be taken from or added to the axle by the use of four bolts and two dowel pins.

Reverting to the Still tube, the reasons for its efficiency are intimately bound up with its construction. Effective turbulence is produced by the positioning of the tubes and the wire leops in the air stream so that the air efficiently sweeps the cooling surface. The number and the arrangement of the tubes are varied to Emit the duty required. It is also usual to vary the amount of cooling surface by altering the number of wire loops disposed per foot of tube. The height and width of the wire loops are also variable and are fixed to suit required conditions.

The rate of heat transfer In the Still tube is such that the speed of water flow through the tube is of great importance. No ordinary gilled tube can transmit heat rapidly enough to warrant a big flow of water. However, asifewer tubes are used in the Still radiator the avkilable water now, as designed for the vehicle, is usually satisfactory, because the speed of flow is correspondingly increased.

We are unable to devote much space to the manufacture of these tubes. The most remarkable kt tomatic winding machines are utilized. There are actually three wires wound at the same time, a steel binding wire, the copper fin wire Which is fed to the winding machine over a pulley suspended by 'a tension spring, and a thin solder wire. The wound tube is first dipped into an acid-flux bath and then inserted between coned nipples connected to a steam boiler and drain 'respectively ; stea at about 350 lb. pressure is then passed through it, is melting the solder wire, which runs

II

ii

ii jilt 6111101111111C freely and secures firmly together the binding wire, the loops and the tube. The length of tube at present dealt with in this, way is 8 ft. Eollowing this, each tube is carefully washed, passed through a lime bath to neutralize any remaining acid, the small screw clamps at each end removed, the tubes cut to the required length on a grindstone and the end winding removed for a sufficient distance for insertion in the radiator plate. It is interesting to Ate that oval tubes can be wound if required.

The test shop is most elaborately equipped. The heat-dissipating test plant consists of a long venturi tube fed by a fan with a capacity of 6,000 cubic ft.

per min. The venturi tube is connected to a velocityreducing chamber on the en.(1 of which is fixed the element under test. The quantities obtained are the heat lost by the water, resistance of the element to air flow and the initial and final temperatures of the air flow. The weight of air flow can be obtained by calculation from this data and the results are checked by readings from the calibrated venturi tube. The heat loss and gain results are usually within 5 per cent. of one another. A demonstration outfit to show the layout and detail arrangement of the Deliandre servo steering.

For testing brakes there is a flywheel to which brake drums are attached. This wheel is driven by an electric motor and is equivalent to the load of one wheel of a 30-cwt. lorry running at 40 m.p.h. The flywheel, which is supported by ball bearings, weighs 1,000 lb. and will run for 11 to 2 hours by its own momentum when the motor is switched off. Useful data are being obtained regarding the retardation of the various brake assemblies.

One plant has been rigged Up for testing the Dewandre vacuum-piston rings. This is arranged to lift a weight of 130 lb. 11 times a minute, and some rings we saw under test had already performed 120,000 operations, for over half of which no oil had been added.