( From the Drawing Boar(

Page 56

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

by Graham Montgonneril

THE USE of lpg as an alternative fuel for automotive use is not new. Several companies specialise in converting existing engines to run on the gas, but most of these are for the light van/private car market.

Rolls-Royce, however, sees a potential for the fuel in the heavier end of the cv market — with certain reservations about the type of operation.

The company, officially the Special Products Division of Rolls-Royce Motors, recently organised a conference, "Gas Power '80", to discuss the various aspects of lpg in the commercial vehicle field. Although it was obviously angled towards Rolls-Royce products, the conference nevertheless produced some interesting information on lpg development.

Gas engine development

Rolls-Royce Motors have, of course, a great deal of experience in both the petrol and diesel engine fields so the company's reasons for following the spark ignition path for an lpg engine are interesting. According to Mr P. Brocklehurst, engineering manager, the combustion characteristics of propane or methane are more suitable for spark ignition with the compression ratio requirements (and therefore the engine structural requirements) being more akin to existing petrol than diesel units.

Although Rolls-Royce thinks that it is possible to use a diesel as a base, the resulting gas engine would be unnecessarily big and heavy.

In considering the power and size of the required package, fuel availability and distribution factors were considered. In the early years of lpg development, it was felt that these factors would favour local rather than long-distance haulage operation.

This limited the upper power target to around 150kW (200bhp) with the lower limit being established by the existence of simple conversions for car derived petrol engines in the power category below 75kW (100 bhp). Having decided upon the basic parameters for a Rolls-Royce lpg development programme, the company's existing product range was examined and from this the "B" range petrol engine was chosen in six and eight-cylinder form.

The development programme was started in 1972 with an investigation into the changes required to optimise engine performance and durability on lpg. One of the major areas of development since that time has been that of the valves and their seats.

Numerous changes have been made to prevent the recession which can otherwise occur with the use of a "dry" fuel like lpg which is devoid of the beneficial effects of additives. The engines were designed with hardened exhaust seat inserts, anyway, so no changes were necessary here. But with the inlets it was a different story, so these have now been changed to a similar specification to that of the exhaust valves.

Combustion work has been aimed at optimising fuel consumption and engine response as well as controlling exhaust emissions. The carburation has been optimised using an Impco 425 constant vacuum gas carburettor with a heated evaporator unit positioned on the engine to minimise the distance between the two in order to aid throttle response. With this system Rolls-Royce has found no need for mixture enrichment for cold start conditions.

The B range engine has an overhead inlet/side exhaust con. figuration combustion chamber which R-R claims gives good combustion control with lpg and hence low emissions. To maximise the combustion efficiency when running on lpg, the compression ratio has been raised from 71/4 to 8:1 based on the guaranteed minimum octane rating of 86 for commercial lpg in the UK.

Fuel consumption

To compare the relative fuel consumptions of different fuels it is necessary to take into account the lower specific gravity of lpg. Rolls-Royce developmeni work has shown that on an mpg basis lpg is about 7.5 per cenl worse than petrol and about 3E per cent worse than diesel.

Thermal studies have beer carried out to ensure optimurr heat rejection paths through the top end of the engine and these have resulted in attention to pis. tons and detail aspects of the coolant flow as well as to the valves and seats already mentioned.

Mr Brocklehurst mentionec that suggestions of engines running "hot" on lpg can largely be explained by what he described as "simple conversions" based on petrol engines and using their existing ignition advance characteristics which have not been optimised to the needs of lpg.

Stressing the greatly reduced contamination of the lubricating oil, Mr Brocklehurst said that the recommended oil change period was effectively doubled when compared to that of an equivalent petrol engine and showed even greater benefit when )mpared with diesel. One very nportant point, however, )ncerns the initial specification F the oil.

Rolls-Royce recommends only ITtain selected products which )ntain low quantities of barium -id calcium additives. Oils conary to this recommendation ave been shown to produce ard combustion chamber deosits which can be detrimental a number of ways including re-ignition, mechanical amage and valve damage.

A solid-state ignition system is sed on the Rolls-Royce lpg enines aimed at maintaining a 3nsistent long-term perform

ance and thus helping to reduce the maintenance requirements.

The two Rolls-Royce engines intended for automotive application are the G61 and the G81 which produce 108 and 157kW (145 and 210bhp) respectively at 3750rpm. As mentioned earlier, Rolls-Royce does not believe that long-distance trunking operations will utilise the claimed advantages of lpg to the extent that the company does not offer the engines for this type of work.

The types of operation that are considered most suitable for the G61 and 81 engines can be summarised thus: a) local delivery/collection vehicles milk collection, foodstuffs delivery, etc; b) municipal vehicles refuse collection, gully emptiers, etc; c) public service vehicles stage carriage, school buses and hotel/airport amenity buses.

Speaking at the conference on the applications of the R-R gas engines, Mr A. L. Gibbs mentioned several specific installations including Clydesdales for the Milk Marketing Board and Shelvoke and Drewry refuse collection vehicles for Croydon Borough Council.

Some three years operation have already been achieved with the Clydesdales which are

powered by G81 engines cut back to 140kW (190bhp) at 3200rpm. One such vehicle operated by the Scottish arm of the Milk Marketing Board has clocked up the equivalent of 322,000km (200,000 miles). I say "equivalent" because this represents 240,000km (150,000 miles) on the road with the remainder referring to engine use while pumping.

Operating costs

Rightly or wrongly, most people think of cost savings as the major advantage of using lpg as an alternative fuel. Like most things, it is not quite as simple as that.

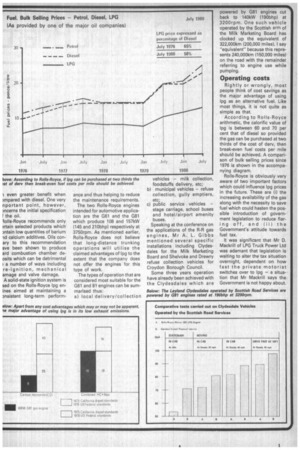

According to Rolls-Royce arithmetic, the calorific value of lpg is between 60 and 70 per cent that of diesel so provided the gas can be purchased at two thirds of the cost of derv, then break-even fuel costs per mile should be achieved. A comparison of bulk selling prices since 1976 is shown in the accompanying diagram.

Roils-Royce is obviously very aware of two important factors which could influence log prices in the future. These are (i) the increasing availability of the gas along with the necessity to save fuel which could hasten the possible introduction of government legislation to reduce flaring off, and (ii) the Government's attitude towards fuel tax.

It was significant that Mr D. Mackrill of LPG Truck Power Ltd was adamant that legislation is waiting to alter the tax situation overnight, dependent on how fast the private motorist switches over to lpg a situation that Mr Mackrill says the Government is not happy about.