Will demount standard make much difference'?

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

THE British Standards Institution is likely to give approval in October to the proposed set of standards aimed at allowing an interchange of bodies between demountable systems from different manufacturers.

A demountable standard is not absolutely essential. The industry has managed quite well without one so far. But it is desirable at it does mean that an operator is not tied to one particular manufacturer.

It was the operators who started the ball rolling via the Freight Transport Association in 1976 to devise a set of standards which would allow such an interchange between different makes of demountable systems be they straight lift or roller contact.

Theoretically an ideal standard is one which would allow an interchange between any combination of system, chassis and body length, but practical considerations ensure that this remains a "theoretical" standard.

The practical difficulties which would arise are easy enough to identify. One of the major disadvantages would be the common leg length necessary to cope with the highest chassis would impose a weight and complication penalty on the smaller and lighter chassis. The DIN standard in use in Germany does achieve a universal interchange, but in this case the cost and weight penalty is magnified out of all proportion as the German system incorporates a require

ment for road/rail body interchange. As the stresses involved in road/rail are much higher than with a road/road operation, the resultant system would be totally unacceptable to the UK operator.

Working party Thus in 1976 the FTA technical committee set up a working party under the chairmanship of Gordon Reed of UBM Transport to see what could be done.

The resultant proposals put forward to the working party by a firm of independent consultants were claimed to achieve compatibility of body locations and fastenings while imposing no restriction on body dimensions beyond those already fixed by the choice of chassis.

Securing the body was taken care of by retractable twistlocks mounted on the chassis. The conventional twistlock housings under the body were replaced by long slotted slides —transverse at the front and longitudinal at the rear. The proposed FTA standard specified a fixed dimension for the spacing between the body runners with a corresponding track or pedestal width for the chassis installation.

No attempt was made to standardise on the lifting method, which was left to the equipment manufacturer.

According to the FTA, the proposed standard would allow interchange between the vast majority of bodies and chassis in use in the UK.

Possibly stirred into action by the FTA, the SMMT representing the demount manufacturers then started to develop its own standard with the result that in April of this year the FTA withdrew its own proposals and put the Association's weight behind the SMMT version.

Although the FTA gave a lot of consideration to continuing with its own scheme, it decided somewhat reluctantly to withdraw it as there was little possibility of it being adopted in the face, not only of the manufacturers' standard with the SMMT, but also of the priority given by the manufacturers to their own system.

Although the FTA felt that il own system did have several al vantages over the SMM proposed standard, it wz thought that to pursue it wou be to encourage a user verst manufacturer argument whic would have completely negatE the whole idea of standardis. tion. As it was, the main aim hind the exercise, ie a standal for interchange, was achieve, Which particular standard thE became secondary.

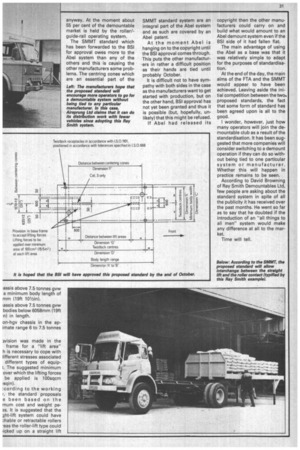

The SMMT standard (detai of which are shown in the a companying diagram) divid( demountable operation in1 three categories: anyway. At the moment about 55 per cent of the demountable market is held by the roller/guide-rail operating system.

The SMMT standard which has been forwarded to the BSI for approval owes more to the Abel system than any of the others and this is causing the other manufacturers some problems. The centring cones which are an essential part of the Left: The manufacturers hope that the proposed standard will encourage more operators to go for a demountable system without being tied to any particular manufacturer. In this case, Airsprung Ltd claims that it can do its distribution work with fewer vehicles since adopting this Ray Smith system.

assis above 7.5 tonnes gvw a minimum body length of mm (19ft 101/2in).

lassis above 7.5 tonnes gvw bodies below 6058mm (19ft n) in length.

on-hgv chassis in the apimate range 6 to 7.5 tonnes wision was made in the frame for a "lift area" h is necessary to cope with lifferent stresses associated different types of equipt. The suggested minimum over which the lifting forces be applied is 100sqcm

;cording to the working r, the standard proposals e been based on the mum cost and weight peas. It is suggested that the ght-lift system could have 7,:hable or retractable rollers -eas the roller-lift type could

■ icked up on a straight lift SMMT standard system are an integral part of the Abel system and as such are covered by an Abel patent.

At the moment Abel is hanging on to the copyright until the BSI approval comes through. This puts the other manufacturers in rather a difficult position as their hands are tied until probably October.

It is difficult not to have sympathy with both sides in the case as the manufacturers want to get started with production, but on the other hand, BSI approval has not yet been granted and thus it is possible (but, hopefully, unlikely) that this might be refused.

If Abel had released its copyright then the other manufacturers could carry on and build what would amount to an Abel demount system even if the BSI side of it had fallen flat.

The main advantage of using the Abel as a base was that it was relatively simple to adapt for the purposes of standardisation.

At the end of the day, the main aims of the FTA and the SMMT would appear to have been achieved. Leaving aside the initial competition between the two proposed standards, the fact that some form of standard has been agreed upon is all to the good.

I wonder, however, just how many operators will join the demountable club as a result of the standardisation. It has been suggested that more companies will consider switching to a demount operation if they can do so without being tied to one particular system or manufacturer. Whether this will happen in practice remains to be seen.

According to David Browning of Ray Smith Demountables Ltd, few people are asking about the standard system in spite of all the publicity it has received over the past months. He went so far as to say that he doubted if the introduction of an "all things to all men" system would make any difference at all to the market.

Time will tell.