A Basic System of Fleet Maintenance

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

BEFORE the war we were all quite justly proud of the high standard of maintenance of our commercial vehicle fleets. For various reasons, over which the average operator or fleet engineer has had little or no control, this standard has fallen coniiderably during the past four or five years.

However, now that the man-power position has eased a little and we are, at least, beginning to get some spares and replacements through, we are, naturally, all doing our best to get the vehicles back into some semblance of fitness.

The difficulty is, of course, that, with few exceptions, the vehicles are all getting old, and are about due to be pensioned off. Four or five years of mechanical neglect, coupled with consistent over-work and over-loading, have not tended to.help them retain the bloom of youth. The task, in perspective, appears gigantic, and quite a few harassed fleet engineers are wondering just bow and where to begin.

The operators and engineers of the larger fleets—those of the 500 to 1,000 and over class—have not, of course, the same worry, They .were, in all probability, firmly committed to a definite maintenance policy prior to the war, and had all the facilities available, waiting for the men to return. It is of the smaller fleets that I write—those comprising about 100 vehicles or under—the operators of which had not the benefit of a standard specification to which their vehicles were built and purchased, but, perforce, took them off the assembly line.

To the engineers of these small fleets, such a settled policy as the " unit change" system is practically out of the question; in fact, to operate it at all, they would require almost as many sets of spare units as they have vehicles, as they, the units, are by no means interchangeable. In consequence, they are more or less compelled individually to recondition' each vehicle, and to keep all the others in service until their turn comes around.

Now, this is a problem, and it is to be hoped in all cases that at least a start has been made, because if there should be any that have not as yet made that start, they are surely going to be in for trouble in the not too distant future with the M. of T. Examiner or Certifying Officer, , These good gentlemen have also had to relax their standards through the war years, but this laxity is not going to continue for ever. Very shortly, now, we may expect a tightening up of these standards; in fact, the first indications are already discernible.

During the past six years I have been privileged, in one respect, to move around the country, where I have seen and operated a few of the accepted systems and methods Of

vehicle maintenance. Having been pre viously engaged foL about 20 years on the viously engaged foL about 20 years on the

practical side of fleet maintenance, it has Vehicle No been possible to form an opinion as to the efficacy of this or that method or

system.

As sometime w happens, I now find myself rather like the man who " took his harp to a party—and no one asked him to play." I am primed with this information, but am no longer in a position to put it to practical use. It is proposed, therefore, to set down a little of it on paper, in the hope that it may be found of use to someone else.

I would say, however, that it is not my intention to dogmatize upon this, of all subjects, as experience has often demonstrated to me that what is practicable and to advantage with one fleet can be almost ou'.. of the question when applied to another. Every fleet, and method of service to it, has its own problems, often aeculiar to that fleet alone.

I say this because I have discovered instances of operators or managers having seen or heard of a certain system or method of maintenance, who have at once insisted on an endeavour being made to apply it, as per specification, to their own, without giving any thought to the fact that it was, in all probability, designed to suit a set of conditions vastly different to those that existed with the organization that they themselves controlled.

For that reason it is proposed to set out what may quite reasonably be called a combination of several systems, the result of which, it is hoped; may be found sufficiently flexible to permit of adaptation to the circumstances and peculiarities of most small fleets.

Vehicle-fleet maintenance is, after all, merely intelligent anticipation of possible sources of trouble, and by adjustment, repair or exchange of components, rendering these sources negative before trouble can eventuate. All this, naturally, should be coupled with an efficient yet not too complicated system of recording. It is really as simple as this, and the development of a system of maintenance for any fleet is but a logical continuation of this dictum.

One knows from practical experience of a fleet's peculiarities; that this or that component, for example, the clutch, needs adjustment at, possibly, 2,000 miles. Then one says, "We will inspect and adjust them at 1,000-mile intervals."

This reasoning and the logical outcome arc applied, in turn, to all necessary routine maintenance operations— always allowing an adequate mileage margin of safety. The greater this margin of safety, the higher the efficiency of the system, and, in consequence, the overall maintenance of the fleet.

. Three Stages of Maintenance

This type of vehicle-fleet maintenance can quite readily be divided into three groups or sections. The first, which may be Section I, is that which takes care of major overhauls. The object of this operation should be, of course, to recondition the vehicle to an "as new" standard at the end of a predetermined period.

Section 2 is that of the sub or dock overhaul, which can be described as interim measures taken between major overhauls, and having as their purpose the repair and replacement of parts or components that have a rate of wear too great adequately to be covered by the major overhaul period. This sub overhaul will take place again at predetermined mileage intervals—generally twice or three times between each major overhaul.

Section 3 may be termed running maintenance. In its turn it takes care of the adjustment, repair, etc., of parts or components that have a wear rate too high for the sub overhaul period adequately to cover.

Although to facilitate description and for ease in administration it is practicable to view the system in three separate sections, actually they are each a complement of the other. to such an extent that the efficiency of any one of them will reflect materially upon that of the others and upon the whole.

say this for the reason that I know of one instance where " near chaos" resulted from a rather half-hearted, and certainly mal-administered, attempt being made to systematize maintenance by adopting one of the sections, whilst practically ignoring the necessity of the others. Fantastic as this may appear to the practical engineer, it is nevertheless true.

Now, although the mileage basis is, without question, the hest foundation upon which to build any maintenance system, it is, in fact, the only equitable basis to be applied to the major elements. In the case of the minor, more frequently recurring operations, however, it is sometimes less corn plicated, from an administrative point of view, ta convert mileage into time periods.

Taking the example previously mentioned, the observation would be: "The average vehicle mileage each week is 500— so we must inspect and adjust all clutches once per fortnight." That is, so many each night or day, as the case may be.

A trifle more difficult to administer, but nevertheless quite equally as important to the efficacy of the system, is the recording of the Operations. The less complicated the method, the greater the chance it has of being readily appreciated by the people whose duty it will be to make it work.

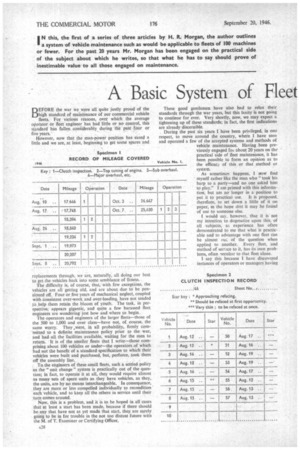

The bedrock of any Mileage system is, naturally, the "record of mileage performed," and to be effective for the requirements of the system it should be cumulative between major overhauls. It should also be capable of showing, with reasonable facility, the mileage interval sinee the last similar operation when applied to any of the component operations of the system.

A specimen page of such a cumulative record, robbed of all non-essentials, is shown in "Specimen I." The key need not, of course, be shown on every page—probably only once on the inside of the cover or binder, if a loose-leaf record be chosen.

It will be noted that upon the specimen page the mileage is entered weekly. This is the maximum period advocated if the system is to retain its simplicity. It will also be seen that the mileage grows week by week between major over

hauls—the "mechanical history card" takes care of the aggregate vehicle mileage beyond this; of that, more later.

Local needs and conditions may warrant an elaboration of this simplified record, although it will be found quite efficient in this guise. After all, it tells, practically at a glance, via a simple subtraction, at any rate, the mileage figure since any last operation of consequence. That this record be maintained religiously by a reliable person, in whatever form be chosen, cannot be Um strongly emphasized; it is the be-all and end-all of any mileage maintenance scheme.

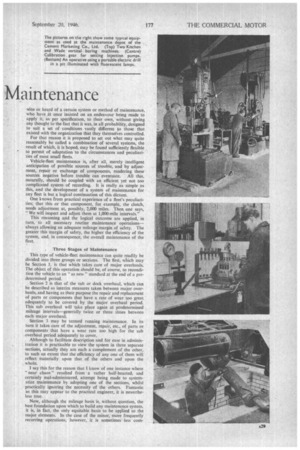

The next essential is that there must be some sort of recording liaison between workshop or garage and office, and sheets after the form of "Specimen 2" have proved themselves for this purpose. The sheets should have a recognized place in the workshop, and should not be put anywhere on the benches or the wall.

Something after the style of a sloping desk, large enough to accommodate them all, is suggested, with, perhaps, a "clip for eitch sheet, and, if possible, a sliding glass-top for the men to rest their soiled wrists upon when entering up the sheets. The incentive should be provided for the staff to treat these sheets as important, and so to keep them reasonably clean. lf this be not done they will scarcely be decipherable when the time comes to collate the details and enter them into the "mileage record."