TWO PROMISING BRAKE INVENTIONS.

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications.

A Self-energizing Brake.

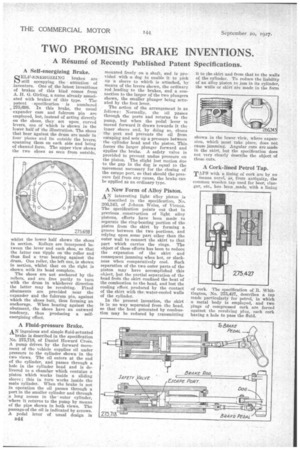

SERELF-ENGIZING brakes are still occupying the attention of inventors. One of the latest inventions of brakes of this kind comes from A. H. G. Girling, a name already associ ated with brakes of this type. The patent , specification is numbered 275,698. In this brake, the usual expander cam and fulcrum pin are employed, but, instead of acting directly on the shoes, they, act upon curved levers, one of which is shown in the lower half of the illustration. The shoes that bear against the drum are made in four pieces and lie outside the levers, spanning them on each side and being of channel form. The upper view shows the two shoes as seen from outside,

whilst the lower half shows the shoes in section. Rollers are interposed between the lever and each shoe, so that the latter can tipple on the roller and thus find a true bearing against the drum. One roller, the left one, is shown in section, whilst that on the right is shown with its head complete. The shoes are not anchored by the rollers, and are free partly to turn with the drum in whichever direction the latter may be revolving. Fixed abutments are provided near the expander and the fulcrum pin, against which the shoes butt, thus forming an anchorage. When bearing against the abutment, the shoes have an outward tendency, thus producing a selfenergizing effect.

A Fluid-pressure Brake.

AN ingenious and simple fluid-actuated

brake is described in the specification No. 275,718, of Daniel Howard Crois. A pump driven by the forward movement of the vehicle supplies oil under Pressure to the cylinder shown in the two views. The oil enters at the end of the cylinder, and passes through a hole in the cylinder head and is delivered to a chamber which contains a piston which works inside a sliding sleeve ; this in turn works inside the main cylinder. When the brake is not in operation the oil passes through a Port in the smaller cylinder and through a long recess in the outer cylinder, where it returns to the pump by means of the pipe shown in both views. The passage. of the oil is indicated by arrows. A pedal lever of usual design is

B44 mounted freely on a shaft, and is provided with a. dog to enable it to pick up a sleeve to which is attached, by means of the levers shown, the ordinary rod leading to the brakes, and a connection to the larger of the two plungers shown, the smaller plunger being actuated by the foot lever.

The action of the arrangement is as follows: Normally, the oil passes through the ports and returns to the pump, but when the pedal lever is moved forward it draws towards it the inner sleeve and, by doing so, closes the port and prevents the oil from escaping and sets up a pressure between the ,cylinder head and the piston. This forces the larger plunger forward and applies the brake. A safety valve is provided to prevent undue pressure on the piston. The slight lost motion due to the gap in the dog is equal to the movement necessary for the closing of the escape port, so that should the pressure fail from any cause, the brake can be applied as an ordinary type.

A New Form of Alloy Piston.

AN interesting light alloy piston is described in the specification, No. 266,343, of Johan-n Weiss, of Vienna. The specification points out that in previous construction of light alloy pistons, efforts have been made to separate the ring-bearing portion of the piston from the skirt by forming a groove between the two portions, and relying upon some part other than the outer wall to connect the skirt to that part which carries the rings. The object of these efforts has been to reduce the expansion of the skirt and consequent jamming when hot, or slackness when comparatively cool. Such separation of the two outer parts of the Piston may have accomplished this object, but the partial separation of the head from the skirt confined the heat of the combustion to the head, and lost the cooling effect produced by the contact of the skirt with the water-cooled walls of the cylinder.

In the present invention, the skirt is in no way separated from the head, RO that the heat generated by combustion may be reduced by transmitting shown in the lower view, where expansion, which must take place, does not cause jamming. Angular Ruts Are made in the skirt, but the specification does not very clearly describe the object of these cuts.

A Cork-lined Petrol Tap.

TAPS with a lining of cork are by no means novel, as, from antiquity, the common wooden tap used for beer, vine‘ gar, etc., has been , made ,with a lining

of cork. The specification ef It. Whittington, No. 275,427,_ describes a tap made particularly for petrol, in which a metal :body is employed, and two plugs of compressed cork are forced against the revolving plug, each cork having a hole to pass the fluid.