MAKING BEST USE OF THE FORD.

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Operation which will Appeal to the Owner, Driver and Repairer.

541.—Another Coil-box Hint.

A frequent trouble in the Ford ignition system is due to the coil-units not making,proper connection with the contacts in the coil-box, more especially those situated on the front side.

In the centre of the box runs a strip of metal to act as a "tie-rod which prevents,' within limits, the bulging of the

sides. If, as so often happens, this comes adrift, packing of sundry descriptions is inserted between the coils and box to ensure proper contact being made.

A better method and, moreover, one which will adapt itself to any varying width of the coil-box is to rivet on the rear side of the latter four springs, as shown in the accompanying sketch. The hand-lever brake pawl spring, part No. 3,463, to give it its correct name, will suit the purpose admirably. The four should be riveted as near as possible to the top edge, when it will be foundthat the end of each spring will reach a point exactly midway down the length of its coil, and so exert even pressure along the whole length of the latter. • The lid of the box should be affixed at all times when the car is on the road, for an accumulation eif road, dust in the bottom of the box is a frequent cause of misfiring, besides which the lid is so constructed that a pressure is exerted on the top of the coil-units, thus keeping them in close contact with the metal conductor strip which runs along the bottom of the box. With a pressure On the coils from both directions one of the principal troubles with this unit is removed.

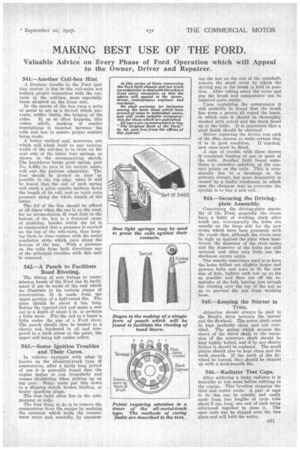

542.—A Punch to Facilitate Band Riveting.

The fitting of new linings to transmission bands of the Ford can be facilitated if use be made of the tool which we illustrate in its various stages of construction. It is made from, the upper portion of a half-round file. The piece should be about 4 ins. long. Soften The tapered end and make a saw cut to a depth of about i• in or perhaps a little more. File the end to a taper a little under the size of a Ford rivet. The punch should then be heated to a cherry red, hardened in oil and tempered to a dark straw at the point, the upper enB being left rather softer.

543.—Some Ignition Troubles and Their Cures.

In vehicles equipped with what is known as the all-metal-track type of commutator, after a fairly long period of use it is generally found that the engine begins to run irregularly and causes shuddering when picking up on top gear. Many users put this down to a slipping clutch, brakes binding, or faulty sparking plugs.

The true fault often lies in the commutator or coils.

The first thing to do is to remove the commutator from the engine by undoing the setscrew which holds the commutator cover and, secondly, by unscrew ing the nut on the end of the camshaft, remove the small cover by which the driving peg in the brush is held in position. After taking away the cover and peg the brush and commutator can be removed quite easily.

Upon examining the commutator it will probably be found that the brush has worn a groove all round the track, in which case it should be thoroughly washed with petrol and the track faced up in the lathe. It is important that a good finish should be obtained.

Before replacing the device, test each of the fibre sleeves to make certain that it is in good condition. If cracked, new ones must be fitted.

A sign of trouble with these sleeves is continual buzzing of one or more of the coils. Another fault found sometimes is excessive sparking at the contact points on the coils. This is occasionally due to a breakage in the primary circuit, but more frequently is caused by a faulty condenser, in which case the cheapest waY to overcome the trouble is to buy a new coil.

544.—Securing the Drivingplate Assembly.

Concerning the driving-plate assembly of the Ford, generally the rivets have a habit of working slack after much use, concequently the holes are usually on the large side for the new rivets which have been procured, with the result that, although the rivets may be tight up against the plate when hammered, the diameter of the rivet sterna and the diameter of the holes are still unequal, and after very little use the slackness occurs again.

The remedy sometimes used is to have the holes drilled out slightly larger and procure bolts and nuts to fit the new size of hole, tighten each nut up as far as possible and then cut off the remainder of the bolt, leaving just enough for riveting over the top of the nut so as to prevent the nut from working loose.

545.—Keep1ng the Starter in Trim.

Attention should always be paid to the Bendix drive between the starter and the flywheel. The screw shaft must be kept perfectly clean and not overoiled. The spring which ,secures the sleeve of the screw shaft to the extension of the armature shaft should be kept tightly bolted, and if by any chance broken it should be replaced. The small pinion should also be kept clean and the teeth smooth. If the teeth of the flywheel be burred, they should be cleaned up with a dead-smooth file.

546.—Radiator Test Caps.

After soldering a leaky radiator it is desirable to test same before refitting to the engine. This -involves stopping the inlet and outlet vents. A pair of caps to do this can be quickly and easily made from two lengths of cycle tube about 5 ins, long, one end of each being solutioned together to close it. The open ends can be slipped over the two pipes and will bold the water.