Power at the Show

Page 37

Page 38

Page 39

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

'WO TRENDS are evident imong the various power units in show at the NEC either on the lands of the manufacturers or nstalled in chassis.

Low engine speed and high orque rise are very evident as is he tremendous increase in harge cooling.

Some years ago (and not all hat far back) the power race i'as on with many engineers poking at 8 bhp per ton and ieyond. Then the oil crisis aused many people to have econd thoughts, and power iutpws tended to polarise round certain levels depending ipon the application.

Because of the increased intrest in fuel economy, the deigners and development enlineers started showing inreased interest in the high torlue rise engine as well as )oking at ways of reducing the laximum rated speed.

The faster the engine turns, ne higher its inherent friction so fly decrease is beneficial proided the injection characterisIcs can be matched so no loss of iower results. The high torque ise engine means that the enine will "hang on' better in the ears thus cutting down the umber of gear changes esecially on long gradients.

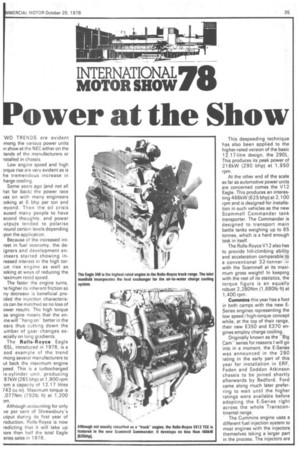

The Rolls-Royce Eagle 65L, introduced in 1976, is a ood example of the trend mong several manufacturers to ut back the maximum -engine peed. This is a turbocharged ix-cylinder unit, producing 97kW (265 bhp) at 1 ,900 rpm 'om a capacity of 12.17 litres 743 Cu in). Maximum torque is ,077Nm (792Ib ft) at 1,200

Dm.

Although accounting for only ve per cent of Shrewsbury's utput during its first year of roduction, Rolls-Royce is now redicting that it will take up lore than half the total Eagle eries sales in 1978.. This despeeding technique has also been applied to the higher-rated version of the basic 12.17-litre design, the 290L. This produces its peak power of 21 6kW (290 bhp) at 1,950 rpm.

At the other end of the scale as far as automotive power units are concerned comes the V12 Eagle. This produces an interesting 466kW (625 bhp) at 2,100 rpm and is designed for installation in such vehicles as the new Scammell Commander tank transporter. The Commander is designed to transport main battle tanks weighing up to 65 tonnes, which is a hard enough task in itself.

The Rolls-Royce V12 also has to provide hill-climbing ability and acceleration comparable to a conventional 32-tonner with the Scammell at its maximum gross weight! In keeping with the rest of its statistics, the torque figure is an equally robust 2,280Nm (1 ,6801b ft) at 1,400 rpm.

Cummins this year has a foot in both camps with the new ESeries engines representing the low speed/high-torque concept while, at the top of their range, their new E350 and E370 engines employ charge cooling.

Originally known as the "Big Cam" series for reasons I will go into in a moment, the E-Series was announced in the 290 rating in the early part of this year for installation in ERF, Foden and Seddon Atkinson chassis to be joined shortly afterwards by Bedford. Ford came along much later preferring to wait until the higher ratings were available before adopting the E-Series right across the whole Transcontinental range.

The Cummins engine uses a different fuel injection system to most engines with the injectors themselves taking a larger part in the process. The injectors are mechanically actuated by the camshaft via push-rods and rockers. As the camshaft still has to perform its "normal"' function of opening the valves, it can be seen that the camshaft is a very busy component in a Cummins engine! Because the injection pressures are generated in the injector itself, the fuel pipes can run at a much lower pressure which Cummins claim minimises leakage problems.

The combustion efficiency of a direct-injection diesel engine can be increased by injecting the fuel over a shorter period. Also delaying the start of the injection can reduce the -negativework done on the piston as it rises on the compression stroke. At the other end of the process, a sharper cut-off at the end of the injection period can help to reduce incomplete combustion which causes black smoke.

To inject the same quantity of fuel in a shorter time, Cummins increased the peak injection pressures by around 15 per cent. This on its own would have increased the stresses on the hard-working camshaft hence the move to a larger diameter camshaft — the Big Cam itself — with a diameter of 64mm compared with the original 51mm (2.5 in from 2.01in).

Cummins have put in a great deal of work into reducing parasitic losses — trimming the maximum engine speed was just a start. For example, their engineers claim to have saved over six horsepower from the water pump assembly alone by using a smaller impeller and reducing the pump speed although the coolant flow rate has been maintained by casting a volute profile into the front of the cylinder block to direct the flow.

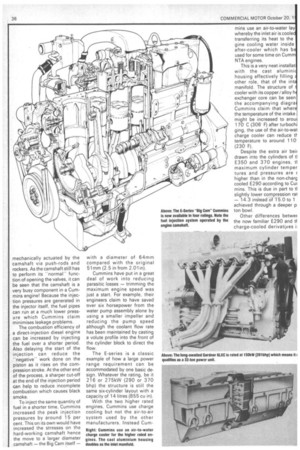

The E-series is a classic example of how a large power range requirement can be accommodated by one basic design. Whatever the rating, be it 216 or 275kW (290 or 370 bhp) the structure is still the same six-cylinder layout with a capacity of 14 litres (855 cu in).

With the two higher rated engines, Cummins use charge cooling but not the air-to-air system used by the other manufacturers. Instead Cum mins use an air-to-water lay whereby the inlet air is coole transferring its heat to the gine cooling water inside after-cooler which has b used for some time on Cumm NTA engines.

This is a very neat installat with the cast alumini housing effectively filling other role, that of the int manifold. The structure of cooler with its copper/alloy h exchanger core can be seen the accompanying diagra Cummins claim that wher the temperature of the intake might be increased to arou 170 C (306 F) after turboch ging, the use of the air-to-wat charge cooler can reduce tF temperature to around 110' (230 F).

Despite the extra air bell drawn into the cylinders of tl E350 and 370 engines, tl maximum cylinder temper tures and pressures are r higher than in the non-charg cooled E290 according to Cur mins. This is due in part to tl slightly lower compression rai — 14.3 instead of 15.0 to 1 achieved through a deeper p ton bowl.

Other differences betwet the now familiar E290 and tt charge-cooled derivati,ves i ude a modified turbocharger latch and an increase in the amber of nozzle spray holes orm eight to nine.

The Cummins E370 does not are the low maximum engine aeed of the other ratings runng up to 2,100 rpm at which ieed it produces 275kW (370 ip) gross to BS AU 141a. Per3ps more important depending 1 your point of view, the maxiurn torque is a prodigious ,440Nm (1.065Ib ft) at 1,400 im.

This enthusiasm for torque — id. not just maximum torque it usable torque — is evident • wer down the Cummins range ith latest derivative of the 8.504. This was introduced a :w weeks ago for various lassis in the Ford D-Series Inge. As installed, the maxiurn torque has been increased / some five per cent but, more wortant from the drive-ability Dint-of-view, the torque rise 3S been more than doubled. Volvo is another manufacirer to turn to charge-cooling ith the announcement of the D 70 F option for the new F7. us is based on Volvo's longirving 6.7-Ittre (409 cu in) degn which in TD 70E form )wered the enormously suc)ssful F86. An air-to-air system used by Volvo with the air diator situated in front of the mventional water radiator.

In this form, the Volvo engine avelops 162kW (217 bhp) at ,400 rpm This is the nett ling to BS AU 141a which sists that the viscous fan, hich is a standard feature, be orking.

While all the other manufacrers have been cutting back

the revs, Gardner has as usual been going its own way untroubled by whatever anyone .else is doing and has actually increased the maximum rated speed for the new 6LXC. The increase is a mere 70 rpm, however, which takes the speed

up to 1,920 rpm at which point the Gardner produces 150kW '(201 bhp) — sufficient to take the long-serving 10.45-litre (638 cu in) engine into the 32ton category for the first time.

Most manufacturers proud of their product are anxious to explain just what has been done to improve the design in cases such as this. Not so Gardner. The company states that the development of the higher power is the result of "higher efficiency which has been achieved by modifications to the cylinder block, pistons, connecting rods, water inlet, and outlet pipes, thermostatic control and exhaust manifolding."

You might ask just what these modifications are, in which case you can keep on asking because Gardner refuses to enlarge upon this very basic information. I hope the company is more forthcoming with its customers.

Although the absence of 145 is regrettable, Leyland Vehicles still have something new to show in the form of the TL 11 engine range.

This range is to progressively replace the fixed head 500Series engines throughout the Leyland range. In contrast to the 500, the TL 11 is a conventional turbocharged urbocharged diesel with a capacity of 11.1 litres (678 cu in). Did I hear someone mention 680?

Two versions are available, the TL 11A and TL 11D, and these replace the 501, 502 and 511 engines currently specified for the Ergomatic truck range. The former is specified for the Bison, Octopus and Buffalo models while the D version comes in in early 1 979 for the Bison and Lynx.

As Leyland says, the TL 11 has many features similar to the proven 680/690 range. And why not? There are many vehicle manufacturers in Europe who owe a lot to this basic design, whether built under licence or merely 'borrowed' so in some ways the wheel has come full circle.

Special attention has been ,paid in the design to ensure consistency of cylinder head gasket clamping and longer gasket life. An ironic situation when one considers that the engine it replaces — the 500Series — was designed with a non-detachable cylinder' head to eliminate the gasket problem entirely. Alterations to the head include the adoption of a 17mm (0.67in) four-hole AM BAC injector.

Oil-cooled pistons are used with the oil being supplied through the connecting rod in preference to crank-case mounted jets. The whole piston and con-rod assembly has been designed for easy withdrawal from the top.

• Prefinished dry chrome liners, secured by Loctite, are used for the TL 11 with the Loctite also acting as a conductor to improve heat dissipation according to Leyland.

The TL 11A produces 156kW (209 bhp) at 2,200 rpm compared with the 1 3 5kW (181 bhp) at 2,000 rpm for the '0" both nett figures to BS AU '141A. The maximum torque figure is the same for both ratings at 820Nm (605Ib ft) at 1,300 rpm.

The A-rating is particularly close in performance to the naturally aspirated L12 engine (derived from an AEC engine rather than a Leyland one as in the Case of TL '11). Leyland argues that this is to satisfy operators who are strongly for or strongly against turbocharged or naturally aspirated engines.

Having used an International engine for their 16-tonner, it was I suppose logical — or political — for Seddon Atkinson to repeat the process with the 300-Series six-wheeler.

In contrast to the 0-358, however, the new International DT-466 is turbocharged. As with Perkins, the type number gives the capacity of the engine in cubic inches which is equivalent to 7.64 litres.

International has been running this engine for some years in the States and, while what works over there does not necessarily work over here, any major problems should be ironed out by now. The crankshaft is induction hardened not only in the journal areas but also at the fillets where failure is most common according to IH. The hardening is deep enough to allow for up to three regrinds.

One feature which the 466 shares with its smaller brother is the provision of valve rotators which turn the valve through 17 to prolong seat life.

The new International engine produces 145kW (194 bhp) at 2,600 rpm with a maximum torque of 610Nm (450Ib ft) at 1,900 rpm. You never know. It might make a useful engine for a lightweight tractive unit.

Perkins have been using airto-air charge cooling on a production engine for some considerable time with the T6.354.4. This produces 116kW (155 bhp) at 2,600 rpm with a maximum torque of 498Nm (36711af1) at 1,700 rpm from a capacity of 5.8 litres (354 cu in).

It is interesting to contrast the approach of Perkins with that of Cummins when the question of chassis installation is considered. Both being manufacturers whose products are fitted into a large number of chassis, any of their designs have to be a compromise to some extent.

Perkins have retained the auxiliary radiator layout and left it up to'the chassis manufacturer as to its initallation whereas Cummins have gone for the airto-water charge cooler which is built in to the basic engine package.

Also on the Perkins stand at the NEC is a new six-cylinder indirect injection engine — the 6.247. On show for the first time, this develops 75kW (107 bhp) at 3,600 rpm and has a maximum torque of 228Nm (1 681b ft) at 2,500 rpm, Although Dorman engines have been popping up from time to time at past shows, this ye( one of the Stafford company range is listed as an option f( the 16-ton ER F.

This is a 90V8 design wii a capacity of 9.1 litres (557 c in). Naturally aspirated, it has gross rating of 119kW (16 bhp) at 2,200 rpm. Althouc the Dorman is an option for ERF, it is the alternative dow rated Gardner 6LXB which exhibited in the 1V1-seri( chassis.

While many manufacture are going for charge-coolir their existing tc engines, son factories are still not 100 p cent convinced of turbochargir in the first place — at least as f as production engines are co cerned. It will be interesting see if for example we will see turbocharged Fiat before ti next Show.

by Graha! M ont gom er