Magyar's tank attack

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

by Steve Banner • French manufacturer Magyar is attacking the UK bitumen tanker market with a 30,000litre triaxle semi-trailer claimed to offer a payload advantage of up to one tonne over its nearest rival. Its unladen weight is no more than 6.9 tonnes.

The Dijon-based company believes that it can capture 20% of British sales, currently running at an estimated 40 to 50 units a year, in 1998. Fruehauf currently dominates this highly specialised sector.

Discharge systems

Equipped with a 3mm stainlesssteel barrel, rather than the more usual 4/5mm mild steel container, Magyar's offering is available with both pump and pressure discharge systems.

"Bitumen is usually discharged under pressure, which means fumes are vented into the atmosphere," says Peter Robinson, a partner in RHM Tank Sales of Bramham, Leeds, Magyar's UK distributor. "As a consequence the bitumen industry could be forced to go pump

discharge on environmental grounds."

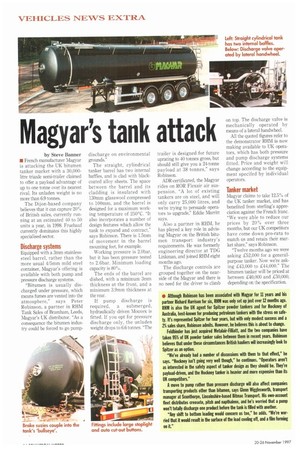

The straight, cylindrical tanker barrel has two internal baffles, and is clad with blackcoated alloy sheets. The space between the barrel and its cladding is insulated with 130mm glasswool compressed to 100mm, and the barrel is designed for a maximum working temperature of 250°C. "It also incorporates a number of design features which allow the tank to expand and contract." says Robinson. There is 1.5mm of movement in the barrel mounting feet, for example.

Working pressure is 2.0bar, but it has been pressure tested to 2.6bar. Minimum loading capacity is 809..

The ends of the barrel are dished, with a minimum 3mm thickness at the front, and a minimum 3.9mm thickness at the rear.

If pump discharge is required, a submerged, hydraulically driven Mouvex is fitted. If you opt for pressure discharge only, the unladen weight drops to 6.6 tonnes. "The trailer is designed for future uprating to 40 tonnes gross, but should still give you a 24-tonne payload at 38 tonnes," says Robinson.

ADR-certificated, the Magyar rides on ROR Flexair air suspension. "A lot of existing tankers are on steel, and will only carry 25,000 litres, and we're trying to persuade operators to upgrade," Eddie Muria says.

Also a partner in RHM, he has played a key role in advising Magyar on the British bitumen transport industry's requirements. He was formerly engineering director at TDG Linkman, and joined RHM eight months ago.

The discharge controls are grouped together on the nearside of the Magyar and there is no need for the driver to climb on top. The discharge valve is mechanically operated by means of a lateral handwheel.

All the quoted figures refer to the demonstrator RHM is now making available to UK operators, which has both pressure and pump discharge systems fitted. Price and weight will change according to the equipment specifed by individual operators.

Tanker market

Magyar claims to take 12.5% of the UK tanker market, and has benefited from sterling's appreciation against the French franc. "We were able to reduce our prices by 20% over three months, but our UK competitors have come down pro-rata to match us and retain their market share," says Robinson.

"Twelve months ago we were asking £52,000 for a generalpurpose tanker. Now we're asking £43,000 to £44,000." The bitumen tanker will be priced at between £40,000 and £50,000, depending on the specification.

• Although Robinson has been associated with Magyar for I.1 years and his partner Richard Harrison for six, RHM was only set up just over 12 months ago. RHM is also the UK agent for Spitzer powder tankers and for Hackney of Australia, best-known for producing petroleum tankers with the stress on safety. It's represented Spitzer for four years, but with only modest success and a 2% sales share, Robinson admits. However, he believes this is about to change.

Feldbinder has just acquired Metalair-Filliatt, and the two companies have taken 95% of UK powder tanker sales between them in recent years. Robinson believes that under these circumstances British hauliers will increasingly look to Spitzer as an option.

"We've already had a number of discussions with them to that effect," he says. "Hockney isn't going very well though," he continues. "Operators aren't as interested in the safety aspect of tanker design as they should be. They're payload-driven, and the Hockney tanker is heavier and more expensive than its UK competitors."

A move to pump rather than pressure discharge will also affect companies transporting products other than bitumen. says Glenn Wigglesworth, transport manager at Scunthorpe, Lincolnshire-based Bitmac Transport. His own-account fleet distributes creosote, pitch and napthalene. and he's worried that a pump won't totally discharge one product before the tank is filled with another.

"Any shift to bottom loading would concern us too," he adds. "We're worried that it would result in the surface of the load cooling off, and a film forming