Oil-cooled Disc Brake

Page 81

If you've noticed an error in this article please click here to report it so we can fix it.

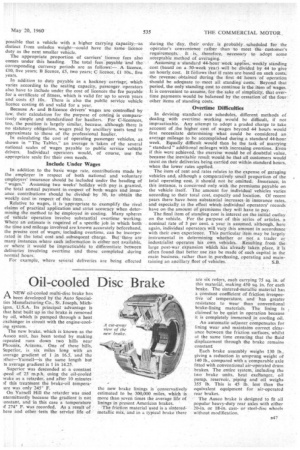

A NEW oil-cooled mtilti-disc brake has

been developed by the Auto Specialties Manufacturing Co., St. Joseph, Michigan, U.S.A. Its principal advantage is that heat built un in the brake is removed by oil, which is pumped through a heat exchanger in circuit with the engine-cooling system.

The new brake, which is known as the Ausco unit, has been tested by making repeated runs down two hills near Phoenix, Arizona. One of these hills, Superior, is six miles long with art iverage gradient of 1 in 16.5, and the ather—Yarnell—is the same length but ts average gradient is 1 in 1425.

Superior was descended at a constant ;peed of 25 m.p.h. using the . oil-cooled 'rake as a retarder, and after 10 minutes A this treatment the brake-oil temperaore was only 245° F.

On Yarnell Hill the retarder was used ntermittently because the gradient is not • onstant, and in this case a temperature 274° F. was recorded. As a result of hese and other tests the service life of the new brake linings is conservatively estimated to be 300,000 miles, which is more than seven times the average life of linings in present American brakes.

The friction material used is a sinteredmetallic mix, and in a typical brake there are six rotors, each carrying 75 sq. in. of this material, making 450 sq. in. for each brake. The sintered-metallic material has a constant coefficient of friction irrespective of temperature, and has greater resistance to wear than conventional brake-lining materials. The lining is claimed to be quiet in operation because it is completely immersed in cooling oil.

An automatic adjuster compensates for lining wear and maintains correct clearance between the friction surfaces, whilst at the same time ensuring that the fluid displacement through the brake remains constant.

Each brake assembly weighs 130 [b.. giving a reduction in unsprung weight of 140 lb., compared with a comparable axle fitted with conventional air-operated drum brakes. The entire system, including the two brake units, heat exchanger, oil pump, reservoir, piping and oil weighs 355 lb. This is 45 lb. less than the equivalent equipment for air-operated rear brakes.

The Ausco brake is designed to fit all popular heavy-duty rear axles with either 20-in. or 18-in, castor steel-disc wheels without modification.