THE COMMER CAR AGRIMOTOR.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

A Self-contained, Two-wheeled Motor Plough Having Many Ingenious Features.

0 RIGINALITY OF DESIGN has always been a Commec Car feature. On the commercial vehicles of that make it was most plainly exemplified in the gearbox. The old (Ammer Car box, with theself-changing gears was an outstanding example of originality even in far-gone days when the commercial motor itself was something of an innovation. Recent, examination of the same • company's after-the-war models has onlyconfirmed our existing impressions as regards this feature.

The Commer Car agrimotor, latest born of the concern's progeny, bids fair to out-rival its older brethren when judged by this same standard_ . Our sub-title describes this machine as being of the self-contained order, and this term has been. selected as indicating, to the general reader, with as little verbiage as nossible,hhe type to which it con forms. On the other hand it should not, strict y speaking, be applied in this case. One is natural y

.inclined to assume, if -the machine is self-contained, that the plough whichis attached 'forms an integral part of the machine as such, and that without it translation of the remainder would be difficult. Actually, however, the Commer Car agrinnotor is designed for universal use, and can rapidly be converted for use as a tractor.

However, no matter for what purpose the machine may profitably be used, the principal object of the patented features to which we are about to draw attention is to fit it more particularly for convenient operation as a plough, and we will therefore, in the main, consider it from that standpoint. In'general appearance it conforms very closely to the typo whiCh, was originated, in this country, at least, by Mr. Wyles, the whole outfit, including, the plough, being balanced about a centrally-disposed pair of driving wheels. A trailing wheel, at the extreme rear of the implement, serves tomaintain the machine in equilibrium when not actually engaged in the soil ; it also acts as a steering wheel. At the front end of the machine there is a skid, which comes into use only when certain manceuvring operations are being carried out.

The engine is at the front, under an ordinary auto

mobile-type bonnet, and the preliminary transmission. to the gearbox is also as is customary in car practice. The final transmission is by chain. and spur gearing, and is arranged so that the wheels can be driven separately if required, or together. The wheels themselves bear on stub axles set eccentric with the main axle, so that by simply turning the latter through a small angle, all the necessary variations inAlepth of ploughing can he had, as well as the very essential setting of one wheel higher than the other, 80 that the furrow wheel runs in the furrow, and the land wheel on the ground, white maintaining the machine itielf approximately level, it is in this arrangement, together with the final drive, that the -interest and novelty 'of the new agrimotor lie. To a consideration of them we shall return a little later.

The chassis projects behind 'the driving wheels, and

the plough is suspended from the rear end, being attached so that the tendency is for the front end of the plough to lift about the trailing wheel as a fulcrum.

The main axle, about which interest centres, is in the form of a crankshaft, with two cranks set at right angles. Upon the pins of these eilinks are mounted the road or ground wheels of the agrimotor. The body of the shaft is carried in bearings which are secured to the frame of the machine. The axle is capable of being rotated in its bearings, and is nominally held stationary by means of a ratchet wheel which is secured to it, and into•the teeth of which engages a pawl. Occasional Movement of the axle, to suit the circumstandes, and to alter the depth of ploughing, etc., is effected by means of pawls and ratchets -controlled automatically. The operation performs this

function through the medium of a hand wheel and screw.

The utilization of a cranked axle, as in this

machine, is particularly ingenious. Let the reader imagine the cranks set so that the near-side one is . standing vertically upwards: The other will, perforce, be horizontal. With the axle so disposed, then, the near:side wheel will be higher than the other. by an amount equal torthe throw of the crank. With the wheels set in this manner, the off-side wheel would conveniently travel at the bottom of a furrow the depth of which was about equal to the crank length, the off-side wheel being upon the land and the machine reinaining horizontal. Now, suppose the axle to be revolved by means of the screw and ratchet gear until both cranks are below the axle, and arranged to form an inverted V. The wheels will now be on a level, one with another, but the axle, which is, to all intents and purposes, integral with the frame, will be lifted above the wheel centres by an amount equal to the total height of the V. In this position the ploughs will be lifted clear of the .ground, for road travelling.

Swinging the axle through an angle of 14) degrees, half a complete revolution, sets the cranks above the axle, thus dropping the latter, with the frame, a total height of twice the height of the V. (It. was before above the wheel centre by a distance equal to the .height.of the V; it is now belo v, the cs.ntre length the same distance). This is the position for commencing to plough a field, or for other cultivating operations.

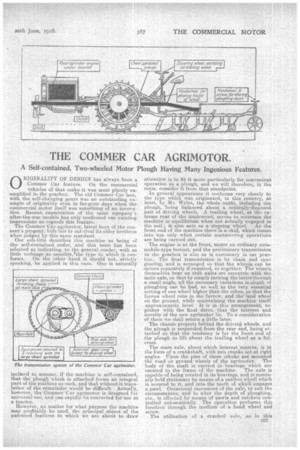

As might be expected, the actual drive to the ground wheels, positioned on an axle as described above, has been the subject of careful thought. The result is as simple, and yet withal as efficient and as likely to give good service, as the cranked axle itself. A countershaft projects from either side of the gearbox, and terminates at each side in a spro,cket wheel. The arrangement so far is very similar to that of a chain-driven lorry, bearing in mind that the gearbox also contains an arrangement of clutches whereby either of the sides may temporarily be disengaged. The drive from each sprocket pinion is by way of a roller chain to a large sprocket which bears upon the

main portion of the axle. Secured to this large sprocket is a spur pinion, which engages -vith an internal gear wheel 4uhich is actually bolted to the ground wheel. As the cranked axle is turned, therefore, in order to adjust the height Of a wheel on the frame, it carries round with it the wheel, and also its internally-cogged gear. The latter moves sweetly round its pinion, the actual gear centre remaining sunchanged. One of the, illustrations which we reproduce shows the principle of the gearing quite Well.

The ratchet gear, by the aid of which movement of the axle is effected, is alsc _an important and interest ing part of the chassis. Although in itself quite simple, as regards its operation, it does not readily lend itself to a short written description such as can be incorporated in an article of this kind, particularly e38 in view of the scarcity of paper. Other details, such as the .suspension of the plough, and the methods of steering, although sound in their way, and not without a certain amount of originality, are not of suffi, • cient importance to justify more than this passing reference at present. In the earlier part of the article mention was made of a skid which was fitted to the front of the machine.

This fitting, normally, is clear of the. ground it comes into use at the headlands when manoeuvring for the next traverse of the field. The procedure, quite novel, is as follows : —The driver, on reaching the side of the field, with ploughs withdrawn, declutches one of his driving wheels, and puts the reverse gear

into mesh. The preliminary effect of this operation, owing to the balance of the tractor and ploughs on its wheels, is to lift the tail of the machine, and consequently the plough, until the latter is quite Clear of the ground. The skid on the front of the chassis prevents this overbalancing from proceeding too far, and so soon as it strikes the ground, the driving wheel, which is still engaged, commences to back, causing the tractor as a whole at the same time to turn round the other wheel as a pivot. The necessary width of headland is thus considerably reduced, and -very quick turns should be possible. The use of this skid, and the facility for lifting the plough by putting the reverse gear into operation is very useful, too, when, in ploughing a furrow, it may be desired to withdraw a little.. Immediately the reverse gear is engaged. the plough is automatically lifted from the soil and the outfit. may be backed quite freely.

Enough has been written to indicate the value of this latest Commer Car product, and we have no doubt that, as regards performance, it will prove a worthy " follower of its road-travelling prototype, the wellknown and deservedly popular Commes Car.