There are few things more irritating than busting a gut

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

to get your vehicle to its destination on time, only to face unloading delays when you get there. But by dragging along a little extra weight in the shape of a piggyback forklift, you can often take back control.

You know what it's like: you've beaten your way through stodgy traffic to get there on time, only to find yourself being kept waiting. Either they can't find a forklift, or they don't have a driver, or perhaps they never had any suitable method of unloading you in the first place. So you wait—and all your subsequent deliveries have to wait too.

The obvious solution is to unload the vehicle yourself. Up to about 75 years ago, the only way of doing this was via a lorrymounted crane, and cranes remain a most effective way of unloading trailers. But they have two major drawbacks: cranes aren't suitable for all types of vehicle, and they suffer from restricted reach so they're not much use if you can't manoeuvre to the precise point of desired delivery.

In these circumstances a piggyback forklift comes into its own, although ironically its very flexibility can lead to problems, as John Shepperson of Derbyshirebased Shepperson Transport explains:

'-i-' "Unloading often takes longer by forklift. If

'1 you can't get close to the delivery point, you might have to run a couple of hundred yards with every palletload."

z'a Sheppersons specialises in brick and block haulage, traditionally core business for lorrymounted cranes. Most of its trailers, predominantly Fruehauf tri-axle flatbeds, are fitted with centre-mounted cranes, but three years ago the company decided to try out a single Moffett Mounty M2003 forklift in a bid to reduce product damage by lifting pallets from below.

"We used to move a lot of tiles but had problems lifting goods off safely because of poor quality pallets," says Shepperson. "With the crane we could only grab the pallets and some of them would just collapse." The trial was a success, and the company bought a second Mounty last year. "Building sites are getting smaller and roads into them are getting smaller too," says Shepperson. "This way we have an advantage in getting in."

Because unloading often takes longer via forklift, Shepperson generally charges a little more for jobs that need one. But customer reaction is hard to gauge. "If you say a job will be an extra £20-30 with the forklift, and then you don't get the job, you do wonder why," he says, although he adds that many customers specifically request the forklift.

"They're a good tool," he remarks, "but if you're not careful you can be used by people in some situations, asking you to move stuff around for them on site, for example. It can be very difficult for a driver to refuse."

On the other hand, of course, the more you help out, the more popular your service is likely to be. That's certainly the experience of Northallerton-based Prestons of Potto. David Preston, operations director at the familyowned firm, says: "Even if things take more time, it's helping the customer, and is more likely to generate future work. We find the little extra time is usually very positively received. Making a delivery this way is often much easier and much more positive in terms of customer reaction."

A forklift can also cut down on manoeuvring time, he adds. It means with artics, say, that you can park them off site and still deliver onto a site where access is a problem or it would be hard to manoeuvre the artic."

Prestons is a general haulage firm with a fleet of just under 200 vehicles and 500 trailers. It uses its two M2003E Mountys exclusively on a contract for a Tarmac subsidiary, delivering mostly to construction sites. "Delivery with the Moffett works well," says Preston. "There is zero product damage as there is no direct contact with the product, and a crane only offers a limited reach away from the trailer, so if access is difficult or ground conditions are bad, it can be hard to get in where the customer wants."

Another benefit he appreciates is that the forklift is not restricted to its host vehicle. "If you're sending three or four trailers to one place you can send the forklift along with the first and it can then unload the others," he points out. "With cranes you can only do that if you have the trailers side by side, and it can be time consuming to manoeuvre them into that position."

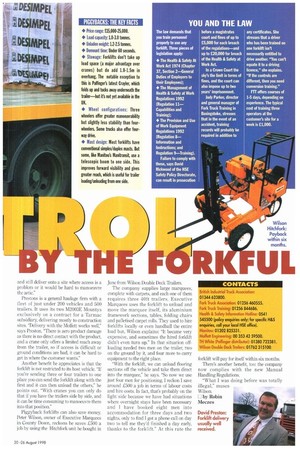

Piggyback forklifts can also save money Peter Wilson, owner of Executive Marquees in County Down, reckons he saves £500 a job by using the Hitchfork unit he bought in June from Wilson Double Deck Trailers.

The company supplies large marquees, complete with carpets, and each one of them requires three 40ft trailers. Executive Marquees uses the forklift to unload and move the marquee itself, its aluminium framework sections, tables, folding chairs and palletised carpet rolls. They used to hire forklifts locally or even handball the entire load but, Wilson explains: "It became very expensive, and sometimes the hired forklift didn't even turn up." In that situation offloading needed two men on the trailer, two on the ground by it, and four more to carry equipment to the right place.

"With the forklift, we can unload flooring sections off the vehicle and take them direct into the marquee," he says. "So now we use just four men for positioning. I reckon I save around £500 a job in terms of labour costs and hire costs. In fact, that's probably on the light side because we have had situations where overnight stays have been necessary and I have booked eight men into accommodation for three days and two nights, only to find I got a phone call on day two to tell me they'd finished a day early, thanks to the forklift," At this rate the forklift will pay for itself within six months.

There's another benefit, too: the company now complies with the new Manual Handling Regulations.

"What I was doing before was totally illegal," muses Wilson.

U by Robin Meczes

PIGGYBACKS: 11IE KEY FACTS

• Price range: £15,000-25,000.

• load capacity: LO-3.0 tonnes.

• Unladen weight: L2-2.5 tonnes.

• Demount time: Under 60 seconds.

• Stowage: Forklifts don't take up load space (a major advantage over cranes) but do add 1.0-1.5m in overhang. The notable exception to this is PaRinger's latest Crayler, which folds up and tucks away underneath the trailer--but it's not yet available in the UK.

• Wheel configurations: Three wheelers offer greater manoeuvrability but slightly less stability than fourwheelers. Some trucks also offer fourway drive.

• Mast design: Most forklifts have conventional simplex/duplex masts. But some, like Manitou's Manitransit. use a telescopic boom to one side. This improves forward visibility and gives greater reach, which is useful for trailer loading/unloading from one side.

YOU AND THE LAW

The law demands that you train personnel properly to use any forklift. Three pieces of legislation apply: • The Health & Safety At Work Act 1974 (Chapter 37, Section 2—General Duties of Employers to their Employees);

• The Management of Health & Safety at Work Regulations 1992 (Regulation 11— Capabilities and Training);

• The Provision and Use of Work Equipment Regulations 1992 [Regulation 8— lirformation and Instructions; and Regulation 9—Training).

Failure to comply with these, says David Rickwood of the HSE Safety Policy Directorate, can result in prosecution before a magistrates court and fines of up to £5,000 for each breach of the regulations—and up to £20,000 for breach of the Health & Safety at Work Act.

In a Crown Court the sky's the limit in terms of fines, and the court can also impose up to two years' imprisonment.

Judy Parker, director and general manager of Fork Truck Training in Basingstoke, stresses that in the event of an accident, training records will probably be required in addition to any certificates. She stresses that a driver who has been trained on one forklift isn't necessarily entitled to drive another. "You can't equate it to a driving licence," she explains. "If the controls are different, then you need conversion training."

M offers courses of 1-5 days, depending on experience. The typical cost of training three operators at the customer's site for a week is £1,000.