An All-British Motor Omnibus.

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

Some Details of the Dennis System.

Messrs. Dennis Brothers, Limited, of Bridge Street, Guildford, are now turning out their latest type of doubledeck petrol 'bus to carry 30 passengers, exclusive of the driver and conductor. The engine has four vertical cylinders, kin. bore by sin. stroke, and at a normal speed of 9oo revolutions per minute gives out 2oh.p. The cylinders are cast separately, and have a crank bearing between each. High-tension ignition is used, the spark control being operated from a lever on the steering wheel. The cooling of the engine is by a honeycomb radiator with a suction fan and a gear-driven centrifugal pump of large capacity. Three forward speeds and one reverse are fitted, the top speed being a direct drive with the second shaft entirely disengaged. The changing of speeds is controlled by a single lever and sliding rod, to which is affixed a fork-shaped arm,

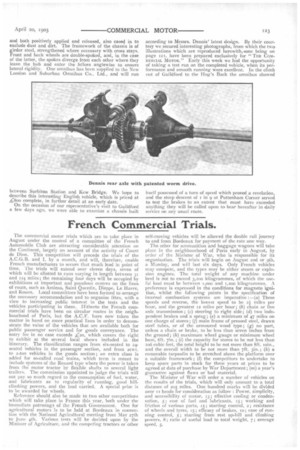

operating the sliding gear on the second shaft. The spindle of this shaft is stationary, being bolted to the gear box ends, and a steel-bushed sleeve revolves upon it, carrying the sliding gears. This arrangement of a bushed sleeve is claimed to be superior to the more usual one of a rod sliding in bearings, as giving greater support to the gears and making them run more smoothly. The transmission from gear box to road wheels is by means of a longitudinal shaft and the makers' patent back axle. The worm and pinion drive, which we hear has given good results in practice, is exceptionally quiet in running, and is fitted with both journal and thrust ball bearings where necessary (as shown). Each bearing on the back axle has 12 by tin, steel balls. The worm pinion is contained in a specially constructed differential gear box. The crank shaft is hardened and ground "dead

true " after being finished on the lathe, a feature conducive to economical wearing of the bearing surfaces. The worm wheel encircles the differential gear, which is of the parallel pinion type, having six pinions and two star pinions. The axle casing is a malleable casting, with specially strengthened outer flanges, into which are screwed and locked the live axle casings, these extending to take the road wheel bearings. The road wheels themselves run loose on these bearings, and are driven through plates fitted on the square ends of the live axle and bolted into recesses in the hubs. It will be seen that the wheels have an independent bearing on which to support the weight of the bus and passengers, the live axle transmitting the drive alone. The front axle is a steel forging, with steering arms having hardened steel cups at the top and bottom of the swivelling pivots. The

bottom cup is made adjustable for wear and is locked in position by a set screw, which avoids the necessity for any pins in the steering arms and thereby strengthens this part considerably. Another interesting feature is the spring drive which conveys the power from the engine through four coil springs placed behind the gear box. The advantages claimed for this are (a) the bus can be started on the top speed if necessary, (b) any harshness of the clutch is absorbed, (c) the gears are relieved, and (d) changing speed is facilitated, all of which points are of importance in the working of such a heavy vehicle as a bus. There are two powerful brakes. The one working on the counter shaft is a large steel drum and band operated by a foot pedal; the other on the back wheels consists of internal expanding steel rings openIng against drums on the rear hubs, compensated,

and both positively applied and released, also cased in to exclude dust and dirt. The framework of the chassis is of girder steel, strengthened where necessary with cross stays. Front and back wheels are double-spoked, and, in the case of the latter, the spokes diverge from each other where they leave the hub and enter the felloes anglewise to ensure lateral rigidity. One omnibus has been supplied to the New London and Suburban Omnibus Co.. Ltd., and will run between Surbiton Station and Kew Bridge. We hope to describe this interesting English vehicle, which is priced at '800 complete, in further detail at an early date. On the occasion of our representative's visit to Guildford a few days ago, we were able to examine a chassis built

according to Messrs. Dennis' latest design. By their courtesy we secured interesting photographs, from which the two illustrations which are reproduced herewithopone being on page 121, have been prepared exclusively for " Tux COMMERCIAL MOTOR." Early this week we had the opportunity of taking a test run on the completed vehicle, when its performance and smooth running were excellent. In the climb out of Guildford to the Hog's Back the omnibus showed

itself possessed of a turn of speed which proved a revelation, and the steep descent of i in g at Puttenham Corner served to test the brakes to an extent that must have exceeded anything they will be called upon to bear hereafter in daily service on any usual route.