PUTTING THEORY INTO PRACTICE

Page 107

Page 108

If you've noticed an error in this article please click here to report it so we can fix it.

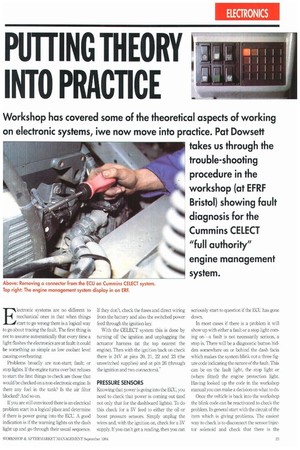

Workshop has covered some of the theoretical aspects of working on electronic systems, iwe now move into practice. Pat Dowsett takes us through the trouble-shooting procedure in the workshop (at EFRF Bristol) showing fault diagnosis for the Cummins CELECT "full authority"

engine management 4N4141% system.

Fidifectronic systems are no different to mechanical ones in that when things c-lart to go wrong there is a logical way to go about tracing the fault. The first thing is not to assume automatically that every time a light flashes the electronics are at fault: it could be something as simple as low coolant level causing overheating. Problems broadly are non-start fault; (31" stop lights. If the engine turns over but refuses to start the first things to check are those that would be checked on a non-electronic engine. Is there any fuel in the tank? Is the air filter blocked? And so on.

If you are still convinced (here is an electrical problem start in a logical place and determine if there is power going into the ECU. A good indication is if the warning lights on the dash light up and go through their usual sequence. If they don't, check the fuses and direct wiring from the battery and also the switched power feed through the ignition key. With the CELECT system this is done by turning off the ignition and unplugging the actuator harness (at the top nearest the engine). Then with the ignition back on check there is 24V at pins 20, 21, 22 and 23 (the unswitched supplies) and at pin 26 (through the ignition and two connectors)..

PRESSURE SENSORS Knowing that power is going into the ECU, you need to check that power is coming out (and not only that for the dashboard lights). To do this check for a 5V feed to either the oil or boost pressure sensors. Simply unplug the wires and, with the ignition on, check for a 5V supply. If you can't get a reading, then you can seriously start to question if the ECU has gone down.

In most cases if there is a problem it will show up with either a fault or a stop light coming on---a fault is not necessarily serious, a stop is. There will be a diagnostic button hidden somewhere on or behind the dash facia which makes the system blink out a three figure code indicating the nature of the fault. This can be on the fault light, the stop light or (where fitted) the engine protection light. Having looked up the code in the workshop manual you can make a decision on what to do.

Once the vehicle is back into the workshop the blink code can be reactivated to check the problem. In general start with the circuit of the item which is giving problems. The easiest way to check is to disconnect the sensor/injector solenoid and check that there is the required supply voltage. Having done so use a mulitmeter to check the continuity of the signal wire up to the ECU (the wiring diagram will show which pin number to test).

Cummins' wiring diagram not only shows the pin number of each connection to the ECU but also all the checking parameters for the sensors. Armed with this you can check out the injector solenoids, engine position/speed sensor, accelerator pedal, oil and water temperature and pressure sensors. Only the boost pressure sensor cannot be checked (as checking with a inultimeter will damage the sensor),

FAULT CODE

Most, if not all, electronic systems you are likely to see on trucks use a combination of sensors, wiring and ECUs. To that end the checking procedures are very similar to those described here. Given that you have a fault code manual and wiring diagram for a system there is no reason why you and your multimeter shouldn't trace most problems.

Our aim throughout this series of articles has been to demystify the language and conventions which can cause many technicians to want to turn their backs on this new technology Once over the phobia created by wires you will find that an electronic unit injector system is less complicated than its mechanical counterpart. Indeed, electronics are easier to fix— no mechanical system tells you what is wrong with it? Equipment like ECHEK, which makes the fault finding process even easier, will become more available to workshops—especially if the proposed changes on Block Exemption go through.

Manufacturers go to great lengths to make the fault finding process as easy as possible and run courses to train those in dealer network and fleet workshops.

Cummins began developing courses on CELECT in the UK in 1991 with full introduction of CELECT-powered trucks which became avail able from ERF, Foden and Seddon in 1993 and DAF in 1994. In order to carry out warranty work on Cummins CELECT engines, a technician will have had to be qualified to meet the engine familiarisation and fault code analysis standards, taken as part of a comprehensive course at the UK Service Training School in Daventry Technicians from fleet workshops can attend the courses at Daventry, the usual approach is through the vehicle manufacturer but direct bookings are available (call Jean Templeton on (0327) 76000 ext 2400).