Devices for Solving the Jacking Problem

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

For Low-loading Vehicles.

MODER.N demands for vehicles having low loading lines, coupled with large-section pneumatic tyres, impose a severe tax upon the ingenuityof jack manufacturers. Not only is the ground clearance of such parts as skirt panels usually on the small side, but: the axle clearance, when a large tyre is deflated, makes, it an awkward proposition to get into position a jack of large dimensions.

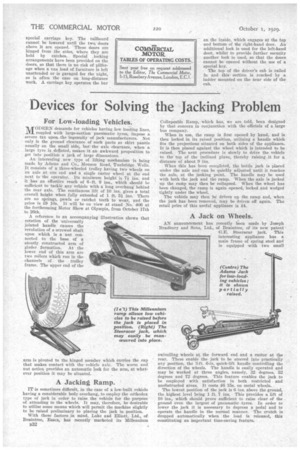

An interesting new type of lifting mechanism is being made by Adams and Co., Monson Road, Tunbridge Wells. It consists of a three-wheeled trolley having two wheels on an axle at one end and a single castor wheel at the end next to the operator. its minimum height. is 71 ins, and it has an effective reach of 6.ft. 9 ins., which should be sufficient to tackle any vehicle with a long overhang' behind the rear axle. The continuous lift of 10 ins, gives a total overall height when fully extended of 1 ft. 51 ins. There are no springs, pawls or ratchet teeth to wear, and the price is £9 10s. It will be on view at stand No. 406 at the forthcoming Motor Show at Olympia, from October 17th to 26th.

A reference to an accompanying illustration shows that rotation of the universally jointed handle causes the revolution of a screwed shaft upon which is a nut connected to the base of a stoutly constructed arm of girder formation. At the lower end of this arm are two rollers whIch run in the channels of the trolley frame. The upper end of the arm is pivoted to the hinged member which carries the cap that makes contact with the vehicle axle. The worm and nut action provides an automatic lock for the arm, at whatever position it may be situated.

A Jacking Ramp.

IT is sometimes difficult, in the case of a low-built vehicle having a considerable body overhang, to employ the orthodox type or jack in order to raise the vehicle for the purpose of attending to the wheels. It may, therefore, be desirable to utilize some means which will permit the machine slightly to be raised preliminary to placing the jack in position.

With these factors in mind, Lake and Elliott, Ltd., of Braintree, Essex, has recently marketed its Millennium B32 Collapsable Ramp, which has, we are told, been designed by that .concern in conjunction with the officials of a large bus company. When in use, the ramp is first opened by hand, and is then locked in its raised position, utilizing a handle which fits the projections situated on both sides of the appliance. It is then placed against the wheel which is intended to be raised. The next procedure is slowly to drive the vehicle to the top of the inclined plane, thereby raising it for a distance of about 9 ins.

When this has been completed, the bottle jack is placed under the axle and can be quickly adjusted until it reaches the axle, at the jacking point. The handle may be used with both the jack and the ramp. When the axle is jacked up the ramp may then be collapsed. When the wheel has been changed, the ramp is again opened, locked and wedged tightly under the wheel.

The vehicle may then be driven up the ramp and, when the jack has been removed, may be driven off again. The retail price of this useful appliance is £4.

A Jack on Wheels.

AN announcement has recently been made by Joseph Bradbury and Sons, Ltd., of Braintree, of its new patent • C.E. Steeracar jack. This interesting appliance has a main frame of spring steel and is equipped with two small swivelling wheels at the forward end and a castor at the rear. These enable the jack to be steered into practically any position, the 3-ft. 6-in, quick-lift handle controlling the direction of the wheels. The handle is easily operated and may be worked at three angles, namely, 32 degrees, 52 degrees and 72 degrees. This feature enables the jack to be employed with satisfaction in both restricted and unobstructed areas. It costs £6 15s, on metal wheels.

The lowest position of the jack is 6 ins, above the ground, the highest level being 1 ft. 7 ins. This provides a lift of 10 ins., which should prove sufficient to raise clear of the ground even the largest of pneumatic tyres. In order to lower the jack it is necessary to depress a pedal and to operate the handle in the normal manner. The crutch is dropped automatically when the load is released, this constituting an important time-saving feature.