For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE Ole TEN SHILLINGS is awarded each week to the sender of the best letter which we publish on this page 6 all °then are paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being published. Mention pour employer's name, in confidence, as evidence of good faith, Address, D. , M. an P., "The Commercial Motor," 7-15, Rasebery Avenue, London., E.C. 1.

Lamps Alight— Light your lamps at 5.0 in London, 5.28 in Edinburgh, 4.56 in Newcastle, 5.6 in Liverpool, 5.5 in Birmingham, 5.1 in Bristol, and 5.50 in Dublin.

A Pump Delivering Valve Repair.

[1795] "ED." (Liverpool) writes :—" Some time ago the water pump on my steam wagon ceased to deliver; and on investigation I discovered that the delivery valve had broken clean in two, just under the head. See sketch [which we have had redrawn.—En.l.

"As is quite usual in these times, we found, on inquiry, that we should have to wait several days if we wanted a replacement. It therefore devolved upon me to effect a repair of the broken one. "This I did in the following manner', and although my original intention was only to enable the engine to keep running until a new valve could be obtained, the patched-up valve did so well that it is being allowed

i to remain_ n use. It looks like rasting for an indefinite period.

"I clamped the two broken pieces of valve together, and drilled a quarter-inch hole right through the centre of both. A set pin of the same diameter-was then driven through the hole and riveted in place."

On Re-lining Brakes. '

The sender of the following communication, has been awarded the 10s. prize this week. _ [1796] " A.J.H." (Cambridge) writes : —" The majority of fitters have trouble when engaged in relining brake shoes, and more particularly those which are situated inside or outside drums on the rear. wheels. No matter how carefully the drums are calipered, or the liner fitted, nine times out of ten, when the shoes are offered up in place, one shoe will be found to bind. The reason is really very easily found, and lies in the fact that either the axle sleeve or bush in the wheel, or both, has worn, so that, when fated, the shoes are not truly central with the drum. "If the wheel and its drum be erected in position while the axle is jacked up, the top shoe (I am writing of the internal-expanding type of brake) will he found to bind on the inside of the drum owing to the wheel, in consequence of its weight and the wear which has taken place, falling a little below the true centre of the axle. An unthinking repairer will probably grind down the apparently offending shoe until it fits, and, satisfied, will refit the wheel and lower the vehicle to • the ground off the jack. The wheel will then take up a new position, leaving the gap in its bearing at-the Op of the axle, instead of below, and will now be a little above the true centre of the axle. In conse.; cluence the bottom shod will now bind, and this again is generally ground to free it. The result is that the equivalent of several hundred miles of wear is ground. off the liners before they start work.

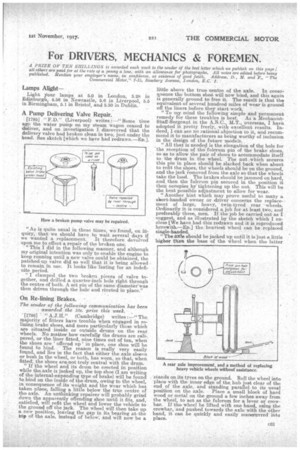

"To my mind the following simple and permanent remedy for these troubles is best. As a MechanistStaff-Sergean.t in the A.S.C., M.T., overseas, I have adopted it pretty freely,. with excellent results. Indeed., I can see no rational objection to it, and recommend it to manufacturers as being worthy of inclusion in the design of the future models. " All that is needell is the elongation of the hole for the reception of the fulcrum pin of the brake shoes, so as to allow the pair of shoes to accommodate itself to the drum in the wheel. The nut which secures this pin • in place should be slacked back when about to refit the shoes, the wheels should be on the ground, and the jack removed from the axle so that the wheels take the load. The brakes should be jammed on hard, and then the fulcrum pin secured in the position it then occupies by tightening up the nut. This will be the best possible adjustment to allow for wear. "Another hint which may prove useful to many a short-handed owner ,or driver concerns the replacement of large, heavy, twin-tyred rear wheels. Ordinarily it is considered a job for at least two, and preferably three, men. If the job be carried out as I suggest, and as illustrated by the sketch which I enclose [We have had this redrawn and it is reproduced herewith.—Ere] the. heaviest wheel can be replaced single-handed.

The axle should be jacked up until it is .just a little higher than the base of the wheel when the latter stands, on its tyres on the ground. Roll the wheel into place with the inner edge of the, hub just clear of the end of the axle, and standing parallel to its usual position on the axle. Place a small block of hard wood or metal on the ground a few inches away from the wheel, to act as the fulcrum for a lever or crowbar. If the wheel be lifted with one hand, using the crowbar, and pushed towards the axle with the other hand, it can be quickly and easily manceuvred into place.