Thornyerofts Gain Australian Coal

Page 102

If you've noticed an error in this article please click here to report it so we can fix it.

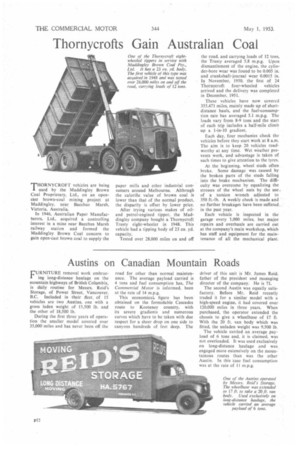

THORNYCROFT vehicles are being used by the Maddingley. Brown Coal Proprietary, Ltd., on an opencast brown-coal mining project at Maddingley, near Bacchus Marsh, Victoria, Australia.

In 1946. Australian Paper Manufacturers, Ltd., acquired a controlling interest in a mine near Bacchus Marsh railway station and formed the Maddingley Brown Coal concern to gain open-cast brown coal to supply the paper mills and other industrial consumers around Melbourne. Although the calorific value of brown coat is lower than that of the normal product, the disparity is offset by lower price.

After trying various makes of oiland petrol-engined tipper, the Maddingley company bought a Thornyeroft Trusty eight-wheeler in 1948. This vehicle had a tipping body of 23 Cu. yd. capacity.

Tested over 28,000 miles on and off

the road, and carrying loads of 12 tons, the Trusty averaged 5.8 m.p.g. Upon dismantlement of the engine, the cylinder-bore wear was found to be 0.005 in. and crankshaft-journal wear 0.0015 in. In November, 1950. the first of 24 Thornycroft four-wheeled vehicles arrived and the delivery was completed in December, 1951.

These vehicles have now covered 355,471 miles, mainly made up of shortdistance hauls, and the fuel-consumption rate has averaged 5.1 m.p.g. The loads vary from 8-9 tons and the start of each trip includes a half-mile climb up a 1-in-10 gradient.

Each day, four mechanics check the vehicles before they start work at 8 a.m. The aim is to keep 20 vehicles roadworthy at any time. Wet weather prevents work, and advantage is taken of such times to give attention to the tyres.

At the beginning, wheel studs often broke. Some damage was caused by the broken parts of the studs falling into the brake mechanism. The difficulty was overcome by equalizing the stresses of the wheel nuts by the use. of a torsion wrench adjusted to 350 ft.-lb. A weekly check is made and no further breakages have been suffered. in the past year.

Each vehicle is inspected in the garage every 1,000 miles. but major repairs and overhauls are carried out at the company's main workshop, which has staff and equipment for the maintenance of all the mechanical plant.