OIL ENGINES FOR COMMERCIAL VEHICLES.

Page 8

Page 9

If you've noticed an error in this article please click here to report it so we can fix it.

Some Account of Successful Experiment Along New Lines Towards the Noduction of a True Oil Burning Engine.

By Henry Sturmey.

WHATEVER MAY BE the case with regard to passenger car engines, there can be no two opinions about the desirability, with engines for all classes of commercial work, of methods by which paraffin or fuel oils may be consumed instead of petrol, not only on account of the greater cheapness of such fuels, but also because of their known higher efficiency. '

In the early days of the motot vehicle, many ex

perimenters recognized this and set themselves to solve the problem, but with only partial success and; as the supply of petrol increased' its many advantages for use in the engines of that day were so apparent that, following the line of least resistance, the paraffin experimenters dropped out and any attempts to re-open the subject met with little encouragement.

Then came the war and the shortage and high price of petrol, and then, too, came tractors, introducing a new field of use in which low cost of fuel was an important factor, with the result that development followed the line of adapting the motorcar petrol engine to the use of paraffin by fuel heating devices and paraffin carburetters. Whilst it is true that some comparative success has been attained, it is admitted that the best of these devices is but a makeshift, and that something more is wanted before success can be considered to have been gained. In America much attention has been given to the subject and, in achieving success in the burning of oil fuel, the inventor has, at the same time, achieved several other highly desirable points for, instead of using some complicated system of carburetter, or fuel heating, or ignition, he has abolished all the usual equipment in this

Fig. I.—Fuel plug, line and obtained a simplicity needle valve, and which is remarkable, as he em fuel pocket. ploys neither carburetter, vaporizer, magneto, batteries, spark plugs, wiring, nor hot bulbs, but both vaporizes and ignites the fuel by the. simple act of compression, for this purposu all the mechanism of the engine consisting of a fuel admission valve, with the usual inlet and exhaust devices.

In this, so far as the principle is concerned, there is nothing new, as it has long been with us in the Diesel e.ngine. But the new system goes one betaer than the Diesel, and may he termed a super-Diesel. This, too, is not altogether new, as it has been known for some years in the Brous engine, and later—in America--in the Hvid system, an improvement of the Brons, and it is a development of the latter type, again, which has now brought the heavy oil auto_ mobile engine within sight of accomplishment. ,

Hitherto, we have been accustomed to associate groat weight and slow speed with the Diesel and all othar high compression engines, and that has naturalb ruled them out of motor vehicle consideration. Bu., when I say that the• latest development has brought us to the stage of a 1,000-revolution engine, 30

weighing only 10 per cent. more than a petrol engine, it will be recognized that a very great step in advance has been made. So far as the Hvid engine is concerned, as a slow-speed engine for stationary commercial and marine purposes, it has been on the market now in the States for about five years. En

gines are now being built over there under licence by seven or eight different firms Specializing on different sizes and types of engine, and they are achieving a very considerable success, about 5,000 bp. being produced of these engines monthly. Briefly, the system consists in the employment of a compression of Oa lbs. per square inch, the combustion chamber being very small and formed with a. small valve pocket, in which the patent fuel valve is , located. The construction of this valve is shown in Fig. 1. It consists of oil and air passages, the former controlled by a needle valve and the latter by the lifting of a small cone valve off its seating, the opening of both passages being simultaneous and controlled by the movement of the tappet of the in-duction valve, the induction valve, it may be said, admitting pure air only to the cylinder. On the other hand, the fuel valve ports, which open on the top centre and remain open. 180° during the induction stroke, admit at the same time a tiny portion of both oil and air, not directly into the cylinder, but into the small fuel cup, which forms the bottom of the fuel plug and occupies the centre of the valve pocket. This small oil cup communicates with the interior of the cylinder by means of two tiny holes drilled in the sides, the size of which may be judged when I say they are usually made with a No. 40 drill, and it may here be said that the size of the holes determines the point of firing, as will be shown later. The operation is as follows:—

On the induction stroke, a full charge of pure air is taken into the cylinder, and at the same time a. proportioned mixture of oil and air,is taken into the fuel cup. Compressien follows, and the heat rises -with the compression until, at 475 lbs., the contained air is practically. red het. --The lopof the stroke is therefore the point of greatest heat and, when this point has -been reached, the heat. is such as to vaporize the lighter constituents of the oil in the cup and enable it, with the contained air, to make an explosive mixture, which is fired by the same heat, an explosion in the Cup takes place, blowing the rest of -the fuel out through the small holes in the cup into the heavily-compressed air in the cylinder, in which it burns. . And here comes-in the of the size of the holes. If these are too large, the heat will be suf6.cient to explode 'the charge before the vision reaches its highest compression and back firing will take place, and if too small the piston Will move too fast for the pressurn behind it to be maintained. , Hence the timing of the engine depends on the size of the holes. At the end of the combustion stroke, the burnt gases are expelled through the exhaust valve in the usual manner,-and the sequence of operationik is repeated.

It will be seen that, unlike a netrol or true explosion engine, the combustion of the fuel does not take place all at once, but gradually, as iii escapes from the holes in, the cup into the contained air. The

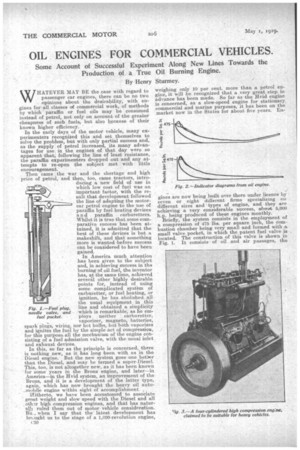

result of this is that this engine, as shown in Fig, 2, gives a diagram much more akin to that of a steam engine than an I.C. engine, a more constant pressure being maintained on the piston than with a true explosion engine, in. which the full force is exerted at once and immediately. begins to fall away. One result of this is to provide an engine of very high fuel efficiency, the fuel consumption of these engines being only .45-.50 lbs. per b.h.p. hour, which is very much less than that of the most efficient LC. engines of the usual type ; whilst another feature is the fact that the slower combustion results in an entire and ;I complete consumption of the whole of the fuel used, with the consequent sequence that the engines are free from carbon deposit.

This slower combustion is, further, of the first importance when the engine is considered from the point of view of weight. When the Diesel engine was first introduced, it was quickly seen that its enormous weight must, for ever, preclude the possibility of its employment for motorcar purposes. The cylinder walls and combustion chamber, in particular, required to the of great strength to withstand the pressure of the explosion .of a charge at so high initial nitial comPression ; whereas, in the Hvid engines; it has been found that the maximum pressure is lower, but is maintained for a greater time, so i that it s only necessary to make the walls of the combustion chamber and other parts very slightly Stronger than for a petrol engine.

The point of interest tothe automobile world is that this fact has been followed up, by Mr. C. E. Sargent, chief engineer to one of the licence working companies, who has now succeeded in producing a practical engine for motor lorry and tractor use weighing, as above said, only 10 per cent. more than for an ordinary conventional lorry outfit..

Experiments in this difection commenced about two years ago, and were carried out for a year with a petrol engine having the cylinder head altered. The results of these experiments having proved successful, the experimenter has now had a speciallydesigned and constructed four-cytinder engine running for some months, a sectional drawing of which is shown in Figs. 4 and 5, and a photographic illustration in Fig. 3. This engine runs at 1,000 revolt'. ..tions, and is operating quite successfully, and it is probable that. before long, it. will come on the market as a commercial article. •