Why go for thin walls?

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

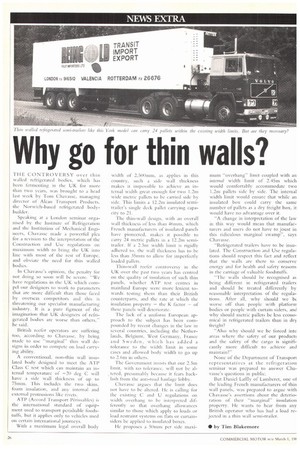

THE CONTROVERSY over thin walled refrigerated bodies, which has been fermenting in the UK for inure than two years, was brought to a head last week by Toni Chavasse, managing director of Alcan Transport Products, the Norwich-based refrigerated bodybuilder.

Speaking at a London seminar organised by the institute of Refrigeration and the institution of Mechanical Engineers, Chavasse made a powerful plea for a revision to the interpretation of the Construction and Use regulations on maximum width to bring the UK into line with Most Of the rest of Europe. and obviate the need for thin walled bodies.

In Chavassc's opinion, the penalty tinnot doing so soon will be severe. "We have regulations in the UK which compel our designers to work to parameters that are more difficult than those faced by overseas competitors and this is threatening our specialist manufacturing industry. it is a pure figment of the imagination that UK designers of refrigerated bodies are worse than others,he said.

British reefer operators are sulli.Ting too, according to Chavasse, by being made to use "marginalthin wall designs in order to compete on load carrying ability.

A conventional, non-thin wall insulated body designed to meet the ATP Class C test which can maintain an internal temperature of —20 deg C will have a side wall thickness of up to 75min. This includes the two skins, foam insulation, and any internal and external protrusions like rivets.

ATP (Accord Transport Perissables) is the international standard of equipment used to transport perishable foodstuff's, but it applies only to vehicles used On certain international journeys.

With a maximum legal overall body width of 2,500mm, as applies in this country, such a side wall thickness makes it impossible to achieve an internal width great enough for two 1.2m wide metric pallets to be carried side by side. This limits a 12.2m insulated semitrailer's single deck pallet carrying capacity to 21.

The thin-wall design, with an overall wall thickness of less than 46min, which French manufacturers of insulated panels have pioneered, makes it possible to Carry 24 metric pallets in a 12.2m semitrailer. If a 2.5m width limit is rigidly adhered to, the wall thickness has to he less than 35min to allow for imperfectly loaded pallets.

Thin-wall reefer controversy in the UK over the past two years has centred on the quality of insulation of such thin panels, whether ATP test centres in mainland Europe were more lenient towards testing them than their British counterparts, and the rate at which the insulation property — the K factor — of' these panels will deteriorate.

The lack of a uniform European approach to the subject has been compounded by recent changes in the law in several countries, including the Netherlands, Belgium, West Germany, France and Sweden, which has added a tolerance to the width limit in sonic cases and allowed body width to go up to 2.6m in others.

The Government insists that our 2.5m limit, with no tolerance, will not be altered. presumably because it fears backlash from the anti-road haulage lobby.

Chavasse argues that the limit does not have to be altered. He is calling for the existing C and U regulations on width overhang to he interpreted differently so that overhang allowances similar to those which apply to loads or load restraint systems on flats or curtainsiders be applied to insulated boxes.

He proposes a 5Ornin per side maxi

mum "overhanglimit coupled with an internal width limit of 2.45m which would comfortably accommodate two 1.2m pallets side by side. The internal width limit would ensure that while an insulated box could carry the same number of pallets as a dry freight box, it would have no advantage over it.

"A change in interpretation of the law in this way would mean that manufacturers and users do not have to joust in this ridiculous marginal swamp", says Chavasse.

"Refrigerated trailers have to be insulated. The Construction and Use regulations should respect this fact and reflect that the walls are there to conserve energy and for health and safety reasons in the carriage of valuable foodstuffs.

"The walls should he recognised as being different in refrigerated trailers and should be treated differently by reasonable interpretation of the regulations. After all, why should we bc worse off than people with platform bodies or people with curtain siders, and why should metric pallets be less economical in refrigerated trailers than in dry freight?

"Also why should we be forced inte areas where the safety of our products and the safety of the cargo is significantly more difficult to achieve and maintain?"

None of the Department of Transport representatives at the refrigeration seminar was prepared to answer Chavasse's questions in public.

But Daniel Laffly of Lamberet, one of the leading French manufacturers of thin mall panels, was prepared to argue with Chavasse's assertions about the deterioration of their "marginalinsulation property. He wants to hear from any British operator who has had a load rejected in a thin wall semi-trailer.

• by Tim Blakemore