HOW TO MAKE

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

E LOAD SECURE. improving Transport Efficiency and be Used. The Correct Roping of Sh The Effects of Weather Cond

Why Thimbles and Rings Should Not Where Dolly Knots are Advantageous. How Loads Should be Roped.

GOODS transport by road, if it is to be carried out in a thoroughly efficient manner and terminal and roadside delays reduced to the minimum, necessitates the employment of knowledge other than that required by the actual running of the vehicles concerned, the obtaining of loads and the general accounting. The knowledge to which we refer is that of rendering the load as safe as possible during the actual transit and the methods by which its .safety can be ensured in a minimum of time.

it may be thought by some that this matter is not one of great importance, but, actually, the effects of lack of knowledge in this respect may be far-reaching; in fact, they may quite possibly represent the difference between profit and loss. Goods may be damaged by being secured carelessly, and it is quite possible for articles to be-lost en route; as a matter of fact, this is a fairly frequent occurrence, and there is always the danger that a portion of the load may, if it falls, be the cause of accident to another vehicle.•Cases have also been known where heavy compensa

tion has had to be paid to persons injured through some article from a vehicle falling upon them.

Exceeding the Maximum Legal Width.

. There is another point to be considered, and one to which we recently referred in our news columns. This is the danger of exceeding the maximum width of a vehicle through careless loading or as the result of a load slipping. In one instance a man was fined for allowing the load on his vehicle to exceed a width of 7 ft. 6 ins., the excess proving to be 11 ins. The defence was that the ropes supporting the load had broken, thus allowing it to bulge at the sides.

In another issue, published a few weeks ago, we Included an article entitled, "The Art of Roping Loads," and this has caused so much interest that we have received further information on the subject from practical men who make other valuable suggestions and point to certain weaknesses which might be found in the methods previously described, which were also contributed by a man with much practical knowledge.

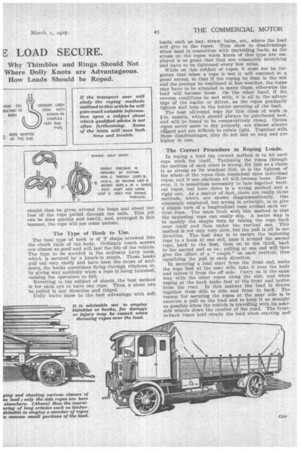

When roping up a load, it is often essential to throw one end of the rope over the load so that it can be drawn down from the other side. For this reason ropes which may be utilized in this manner should not be equipped with metal thimbles or rings, as they may strike lamps, windows, etc., and possibly injure persons passing; in addition, hooks are of little use, as the jolting of a vehicle causes constant stretching of the ropes, no matter how tightly the he secured. Once slightly loosened, a big jar caused by a deep pothole might be sufficient to let the majority of the hooks drop clear.

The method of roping a sheet so that it can conform to tile shape of the load is not liked, as it is claimed that in using this method the sheet is apt to slide along the rope, which is then likely to become loose. It is also pointed out that as the sheet is usually oblong it is almost impossible to secure a load without folding over the corners. It is only a net which can satisfactorily be employed without such a procedure.

Coiling Ropes for Storage.

Ropes, etc., hanging from vehicles are liable to cause attention from the police; they are exposed to all weather conditions and are easily lost or stolen.

The folding of ropes by hand is by far the quickest method, and it does not require the use of bars, etc., around which to wind or carry them. In folding a rope, one end should be held in the left band and the other hand slid along the rope until the arms are outstretched. The right hand should then grip the rope and pass a fold of it to the left hand, the process being repeated until only a yard is left. Five or six twists should then be given around the loops and about one foot of the rope pulled through the coils. This job can be done quickly and neatly, and, arranged in this manner, the rope will not come undone.

The Type of Hook to Use.

The best type of hook is of T shape screwed the chock rails of the body. Ordinary coach screws are almost as good and will last the life of the vehicle. The type to be avoided is the ordinary lorry _hook, which is secured by a knock-in staple. These hooks pull out very easily and have been the cause of accidents, the hooks sometimes flying through windows or, by giving way suddenly when a rope is being tautened, causing the operators to fall.

Reverting to the subject of sheets, the best method is for each eye to have one rope. Thus, a sheet can be pulled in any direction and ridged.

Dolly knots show to the best advantage with soft into loads, such as hay, straw, bales, etc., where the load will give to the ropes. They show to disadvantage when used in connection with unyielding loads, as the stress on the ropes when knots of this type are employed is so great that they are constantly stretching and have to be tightened every few miles.

While on this subject of ropes, it must not be forgotten that when a rope is wet it will contract to a great extent, so that if the roping be done in the wet and the journey be continued in fine weather, the ropes may have to be attended to many times, otherwise the load will become loose. On the other hand, if the reverse conditions be met with, it is all to the advantage of the loader or driver, as the ropes gradually tighten and help In the better securing of the load.

The best all-round rope for this class of work is fin, manila, which should always be purchased new, and will be found to be comparatively cheap. Cotton rapes never seem to dry properly, are almost always ragged and are difficult to retain tight. Together with these disadvantages, they do not last so long and are higher in cost.

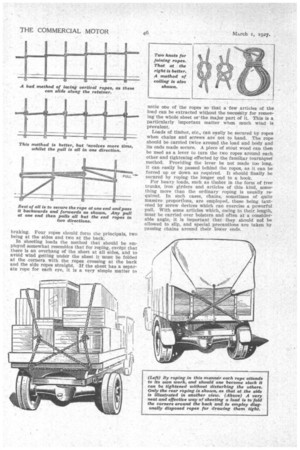

The Correct Procedure in Roping Loads.

In roping a load the correct method is to let each rope work for itself. Tautening the ropes through the medium of each other is wrong, for just as a chain is as strong as its weakest link, so is the tightest of the whole of the ropes then dependent upon individual ropes, and if one slackens all will become loose. However, it is sometimes necessary to lace together vertical ropes, but here there is a wrong method and a right one. As a matter of fact, there are really three methods, which are shown diagrammatically. One commonly employed, but wrong in principle, is to give a simple turn of a longitudinal rope around each vertical rope. The main fault with this method is that the tautening rope can easily slip. A better way is to modify the simple turn by taking the rope back over itself and then under the vertical one. This method is not only very slow, but the pull is all in one direction. The best way is to secure the tautening rope to a hook at one end, pass it around the second rope, back to the first, then on to the third, back to the second and so on; pulling at one end will then give the effect of a " couple " on each vertical, thus equalizing the pull in each direction.

In securing a load start from the front end, make the rope fast at the near side, take it over the body and tauten it from the off side. Carry on in the same way with the other Dopes along the side, and when roping at the back make fast at the front and tauten from the rear. In this manner the load is drawn together from side to side and front to back. The reason for securing the ropes at the near side is to exercise a pull on the load and to keep it as straight as possible when the vehicle is travelling with its nearside wheels down the camber of the road. The frontto-back ropes hold steady the load when starting and braking. Four ropes should form the principals, two being at the sides and two at the back.

In sheeting loads the method that should be employed somewhat resembles that for roping, except that there is an overhang of the sheet at all sides, and to avoid wind getting under the sheet it must be folded at the corners with the ropes crossing at the back and the side ropes straight. If the sheet has a separate rope for each eye, it is a very simple matter to untie one of the ropes so that a few articles of the load can be extracted without the necesSity for removing the whole sheet or\the major part of it. This is a particularly important matter when much wind• is prevalent.

Loads of timber, etc., can easily be secured by ropes when chains and screws are not to hand. The rope should be carried twice around the load and body and its ends made secure. A piece of stout wood can then be used as a lever to turn the two ropes around each other and tightening effected by the familiar tourniquet method. Providing the lever be not made too long, it can easily be passed behind the ropes, as it can be forced up or down as required. It should finally be secured by roping the longer end to a hook.

For heavy loads, such as timber in the form of tree trunks, iron girders and articles of this kind, something more than the ordinary roping is usually required. In such cases, chains, sometimes of quite massive proportions, are employed, these being tautened by screw devices which can exercise a powerful pull. With some articles which, owing to their length, must be carried over bolsters and often at a considerable angle, it is important that they should not be allowed to slip, and special precautions are taken by passing chains around their lower ends.