Adelaic of

Page 126

Page 127

Page 128

Page 129

If you've noticed an error in this article please click here to report it so we can fix it.

10-Year Plan Idernization

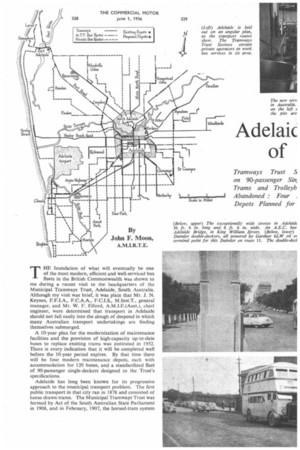

Tramways Trust 5 on 90-passenger Sin, Trams and Trolleyb Abandoned : Four Depots Planned for THE foundation of what will eventually be one of the most modern, efficient and well-serviced bus fleets in the British Commonwealth was shown to me during a recent visit to the headquarters of the Municipal Tramways Trust, Adelaide, South Australia. Although my visit was brief, it was plain that Mr. J. N. Keynes, F.F.I.A., F.C.A.A., F.C.I.S., M.Inst.T., general manager, and Mr. W. F. Elford, A.M.I.E.(Aust.), chief engineer, were determined that transport in Adelaide should not fall easily into the slough of despond in which many Australian transport undertakings are finding themselves submerged.

A 10-year plan for the modernization of maintenance facilities and the provision of high-capacity up-to-date buses to replace existing trams was instituted in 1952. There is every indication that it will be completed well before the 10-year period expires. By that time there will be four modern maintenance depots, each with accommodation for 120 buses, and a standardized fleet of 90-passenger single-deckers designed to the Trust's specifications.

Adelaide has long been known for its progressive approach to the municipal transport problem. The first public transport in that city ran in 1878 and consisted of horse-drawn trams. The Municipal Tramways Trust was formed by Act of the South Australian State Parliament in 1906, and in February, 1907, the horsed-tram system was bought out by the Trust for 1280,000. On March 9, 1909, the Trust's electric tram service was officially opened.

In common with nearly every other principal city in Australia, Adelaide placed much dependence upon its trams, but on March 25, 1925, the first petrol bus service was introduced, this being between Adelaide and Fide. The vehicle employed was a Mack 27-seater. From that date the bus fleet grew steadily.

With one eye always open to possible improvements, the Trust introduced the first trolleybus to run in Australia and an experimental service was operated for n years between Payneham and Paradise. This was worked over an existing tram route, using a single-pole pick-up from the overhead wire and a skid-type rail return through the tram rails.

In September, 1937, a further service between Adelaide and Tusmore, which was later extended to Largs and Semaphore, was instituted, The Trust now has a fleet of 91 trolleybuses, consisting of 30 A.E.C. and five Leyland double-deckers, and 26 Leyland and 30 Sunbeam single-deckers. Under the current modernization scheme, however, none of these vehicles will be running after 1962.

A similar fate Ties in store for the 167 trams at present operated by the Trust. So far, nine tram routes have been converted to oil-engined bus operation and as new buses are delivered the remaining routes will be abolished. In 1937 there were 307 trams and 58 motorbuses, the tram routes totalling 76.11 miles, compared with 21.69 miles for the buses. There are now 167 trams, 91 trolleybuses and 154 motorbuses. The trams operate over 69.27 route-miles, whilst the trolleybuses and motorbuses work over 22.55 miles and 38.33 miles, respectively.

The bus fleet at present consists of 17 Ansair rearengined single-deckers—Australian-built vehicles with Ford V8 power units-49 A.E.C. Regal Mark III singledeck oilers, 15 Daimler Gardner-engined double-deckers and 70 A.E.C. Regal Mark IV underfloor-engined single deckers. In addition to these vehicles there are a Daimler Freeline, an A.E.C. Regal Mark IV with Monocontrol transmission, and a Leyland Royal Tiger Worldmaster with Pneumo-Cyclic transmission.

These three buses have been running as prototypes, with the result that orders were placed for 70 A.E.C. and 75 Leyland. At the time of my visit, the first A.E.C. was in the hands of the bodybuilders and should now be in operation.

Although the two types are virtually identical in appearance, there is a slight difference in overall length. Having 19-ft. 6-in, wheelbase chassis, the A.E.C. buses are 36 ft. 6 in. long, whilst the Leyland buses have a 24-ft. wheelbase and an overall length of 37 ft. Both types are 8 ft. 6 in. wide and in this respect the Trust has cause to be thankful to the original town planners of Adelaide, who laid out the city with its symmetrical network of wide streets.

Adelaide-built Bodies All the bodies on these vehicles are being built by J. A. Lawton and Sons, Ltd., Adelaide, and are 40-seaters with standing capacity for 50 persons. A tubular-steel body frame is employed, with aluminium interior and exterior panelling. With a view to keeping the weight as low as possible, Duralumin has been used for the bumpers and grab rails and, with a view to reducing further the weight and 'the cost of replacement and repairs, new materials, such as plastics, are being considered for certain interior and exterior components.

There are three jack-knife air-operated doors. The rear one is used as an entrance and is adjacent to a large low-level loading bay to speed up the entry of passengers. This bay has two seats and there is one step up from it into the main body. All the doors are under the direct control of the driver.

Although underfloor-engined chassis are the only type suitable for three-door bodies, the high floor line is still a considerable problem. A low entrance can be achieved at the rear by using a dropped rear-frame extension, but several steps are necessary at the centre and front exits. At present, there is little that can be done to ease this problem, and the only possible alternative is, in the opinion of Mr. Elford, a rear-engined chassis, provided that this can be designed so as not to obstruct the rear entrance.

The Adelaide Tramways Trust is, like all other Australian municipal passenger undertakings, faced with the problem of falling revenue because of the prevalence of private cars, and more and more people prefer to use their own transport. To combat that trend, the Trust decided that it would have to make its buses as attractive and comfortable as economic considerations would allow.

Each seat, for example, has an individual reading light, and air ducts run along each side of the body to provide adequate fresh-air ventilation, the intakes for these ducts being above the windscreen. Further ventilation is provided by the sliding windows on each side of the body, which are glazed with toughened glass and have both heat and glare-reducing properties.

Several Safety Features Safety has received due consideration in the design of these vehicles. The deep windscreen, besides improving the appearance, enables the driver to see within 2 ft. 6 in. of the front of his bus. The driver-operated doors are another safety factor and the pneumatic system controlling them incorporates an additional air reservoir to avoid any dangerous reduction of air pressure available for braking.

Large stop lights are incorporated in the rear panel of each bus and, although they are not legally recognized, the use of flashing-arrow direction indicators in these panels is also being considered.

A further safety feature is an 1-in.-thick steel plate inside the front panelling. This protects the driver from serious injury in the event of a front-end collision and it is considered by the Trust far to outweigh the disadvantage of its weight.

The average unladen weight of these buses is 8f tons, of which 4f tons is on the front axle. When fully laden they run at over 14 tons gross, but power-assisted steering has not been found necessary, although its use is being considered. The suspension of a vehicle of this capacity, in which the laden and unladen weights vary greatly, can be troublesome, and one of the A.E.C. chassis is, at the moment, running with Gregoire coilspring units at both axles. The performance of this system is reported to be favourable and it will possibly be incorporated in other chassis.

The area covered by the Trust is within an approximate 10-mile radius of the city's centre. It is almost at and consists for the most part of industrial and suburban residential districts. There are 130 route-miles covered by 14 tram, six trolleybus and 12 motorbus services. The shortest route is the 3.4-mile tram service from the City to St. Peters, whilst the City-Largs Bay trolleybus service (11A miles) is the longest. None of the routes operated is a paying proposition on the basis of comparing revenue received with total operating costs, the 1955 statement of accounts showing a deficiency of 12.51d. per traffic-mile.

There is much local industry along Port Road, which runs between Adelaide and Port Adelaide. This tends to create two-way morning and evening peak loading. These peaks are steep and three times as many buses are needed at such times as are used during off-peak periods.

To cope with them, the Trust licenses private operators to serve certain areas. Last year 114 vehicles were thus licensed, covering a route mileage of 106.26 and carrying 13.3m. passengers. At peak periods the maximum frequency of any service operated by the Trust is 50 seconds, which compares with the minimum off-peak figure of 40 minutes on some suburban services.

Each fare stage is about a mile long and 5d. is charged for the first stage, plus 2d. per stage to the fourth and I d. extra per section thereafter. Children can travel over the first section for 2c1., plus id. per stage for the next three, the maximum fare being 6d. Monthly concession tickets are issued with a 17k-per-cent. reduction, and schoolchildren's tickets carry a 331-per-cent. reduction.

Manually Issued Tickets • Ticket-issuing machines are not used. All tickets are carried in stapled bunches and clipped manually. The 17 Ansair and 49 A.E.C. Regal Mark III buses have one-man operation. It is intended that the new 90-passenger vehicles should also be used as one-man buses, but at the moment the Trust is receiving strong opposition from the unions, who have always been against one-man operation but have recently agreed to let buses of up to 32 ft. overall length be worked by a driver alone.

Manual ticket-issuing methods will still be retained until a really efficient type of ticketand change-issuing machine is available. Mr. Keynes considers that the ideal machine must be suitable for use by either driver or conductor, which means that it must be light, portable and simple to operate on a crowded bus. During the year 1954-1955, 66.4m. passengers were carried over 10.2m. miles. The number of passengers carried was 525,603 fewer than in the previous year, despite an increase in population of 21,000, to 496,000, within the area covered by the Trust.

The M.T.T. has over 2,000 employees. This staff is adequate for current needs, with the exception of skilled tradesmen. This shortage of skilled labour is general throughout Australia and has been only partly satisfied by immigration schemes. Adelaide is fairly well placed for labour and although the Trust's average turnover rate of 24 per cent, seems high, it is low when compared with that of other industries in the area.

Facilities for employees are generally good. In the new depot at Hackney Road South, modern messrooms, locker rooms, shower and toilet facilities have been provided. There is a Tramways Club subsidized by the Trust, which operates a canteen selling groceries, confectionery and other small items, in addition to providing certain sick and death benefits to members.

Employees who are paid by the day can also become members of a retiring and death gratuity scheme, which provides 80 weeks' pay for 30 years' service. Sick leave is based on current Government and union awards and agreements, but is generally in the region of five days a year on a cumulative basis. Staff employees are entitled to six months' long-service leave after 20 years and a sick-pay allowance, also cumulative, of 10 full and 10 half pay-days a year.

The retiring age for all employees is 65. New employees are required to pass a medical examination before being enrolled, and motormen and bus drivers have to undergo further medical examinations at the ages of 55 and 60, and each year after 60 until retirement.

The central workshops and bus, tram and trolleybus depot are at Hackney Road, which is a mile from the centre of the city. To the south side of the central building a new servicing depot and bus park have been built. These are to form the pattern for another layout to the north of the workshops, a second at Glenunga and a rebuilt depot at Port Adelaide. The present building at Port Adelaide is used as a motorbus and trolleybus depot.

The new depot at Hackney Road South is impressive in layout and function, and is the result of extensive study of the latest shops to be found in Europe and the United States, The workshop building is set in a corner of a large open park, but there is a road running round the back of it. As each bus comes off duty it passes under a refuelling gantry, where fuel tanks are topped up and engine oil and water levels are checked. Drivers report vehicle defects at a gatehouse adjacent to the gantry.

Ready for Next Duty Having been refuelled, buses which are not due for service are run into the park, where they are then ready for the next tour of duty, whilst vehicles scheduled for maintenance are run straight into the depot. The depot itself has a sunken servicing area and 11 pits. Two of these are open at each end, so that buses can be run straight through. The pits are equipped with Gilbarco lubricant-dispensing equipment for under-chassis greasing. One has Servex wheel-alignment equipment, and two have built-in hydraulic hoists.

The pits are equipped with fluorescent lighting and are completely tiled. When I visited this depot at 9 p.m. I was particularly impressed by the absolute cleanliness of the pit areas, although each was in use.

Every fortnight chassis parts are lubricated and an underneath inspection is carried out. At 5,000 miles comes the A dock, during which all oils are changed, and at 40,000-50,000 miles there is the B dock, which consists basically of valve grinding and mechanical inspection.

Heavier docks are done in the main workshops behind the Hackney Road South depot. These workshops are equipped to handle all classes of repair. Engine overhauls could be undertaken there, but for the most part replacement units are carried.

Reconditioning of worn components has been facilitated by the use of Metco metal-spraying and there is a fully equipped paint and body-repair shop. The Trust even carries out its own tyre retreading and two Olympic X2 general-purpose machines are used in the workshops. These machines have a capacity of about five tyres a day and the process of retreading has been speeded up by applying solution by spray-gun instead of by brush. Each tyre is given three re-caps, the first at 18,000 miles. The average life of a tyre is 60,000 miles.

Minor Engine Overhauls C docks are done in the main workshops at 80,000100,000-mile periods and consist of minor engine overhauls, during which piston rings are changed and small repairs effected, and complete mechanical, electrical and body inspections carried out. The main item on the maintenance schedule is the D dock, which comes at 160,000-200,000-mile intervals. At this mileage there is a general overhaul of all mechanical, electrical and body components. Bodies are removed and the completely overhauled vehicles are repainted before going back into service. Vehicle-repair history cards are kept and all repairs, however minor, are entered on them.

The Trust is tackling the future with confidence, despite financial difficulties, which, last year, warranted a State grant of £600,000 towards working expenses. Even with this grant the net operating deficiency was £139,423. It is hoped, however, that by the eventual conversion of all routes to oil-engined bus operation and the drastic modernization of workshops and servicing depots, this loss will be much reduced.