Experienef

Page 72

Page 73

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

of MILE

:7ounts in the Construction VEHICLES

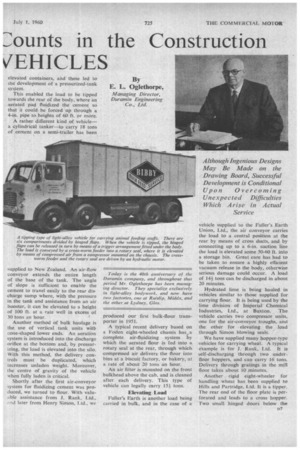

GREAT advances have been made in recent years in the transport of powdered loads in bulk. cement and flour being two traffics that spring readily to mind. Bulk handling affords obvious economic advantages by eliminating sacks and the labour to handle them, but it also presents problems which an operator should carefully consider before embarking upon this particular system of transport.

Light-alloy panelling is ideal for flour-carrying bodywork, but the body should be thoroughly cleaned, if a ,vehicre is likely to lie off the road for any length of time. In cement haulage, some air hardening can occur, and aeration pads, which are essential for speedy unloading, must be kept opera

ting freely. Some other powdered loads are potentially dangerous, and the possibility of explosion must not be overlooked.

There is urgent need for the standardization of uptake pipework and connections. Pipelines of 4-in. diameter make for easier handling in discharge compared with 3-in. pipelines. There is a wide variation in the type and size of connection, ranging from the 3-in. V thread to 4-in. V or 4-in, round threads. As low pressures are generally acceptable, the 4-in. round thread would appear to be the most suitable to adopt as standard, It is quick and easy to handle, and is not easily damaged.

Air compressors present a problem. Clean, dry air is essential in dealing with nearly all powdered loads, and the blower type of unit has much in its favour. Noise, however,, is• objectionable at the delivery point and the introduction of methods of silencing has received much thought from the manufacturers.

New developments are always in progress. Those now under way are concerned chiefly with payload, speed of discharge, economy of compressed air, silence, greater reliability and the reduction of cost. All these problems have been tackled vigorously, and lessons learnt are being embodied in a new vehicle which my company will exhibit at the Commercial Motor Show in September.'

Important Qualities

The use of light alloys has played an important part in the progress of bulk-haulage vehicles. Its freedom from rust and hygienic ,qualities are important. The substantial increase in payload that it permits through reduction of unladen weight is something that no operator can afford to overlook.

In the early days of bulk haulage, the tipping body for cement served its turn but had obvious disadvantages. To overcome them my company were early in the field in producing a bulk vehicle employing the air-conveyor principle of making the load fluid. It was provided with a controlled-dis• charge system. A typical vehicle of this kind was supplied to carry Blue Circle cement. It had loading hatches on the roof and three conveyor bays The discharge system of aeration enabled up to 16 tons to be delivered in about 10 minutes. This type of vehicle is particularly useful where there is a large and regular intake of cement. Later there were demands for bulk cement to be delivered into supplied to New Zealand. An air-flow conveyor extends the entire length of the base of the tank. The angle of slope is sufficient to enable the cement to travel easily to the rear discharge sump where, with the pressure in the tank and assistance from an air booster, it•can be elevated to a height of 100 ft. at a rate well in excess of 30 tons an hour.

Another method of bulk haulage is the use of vertical tank units with cone-shaped lower ends. An aeration system is introduced into the discharge orifice at the bottom and, by pressurizing, the load is elevated into the silo. With this method, the delivery controls must be duplicated, which increases unladen weight. Moreover, the centre of gravity of the vehicle when fully laden is critical.

Shortly after the first air-conveyor system for fluidizing cement was produced, we turned to flour. With valuable assistance from I. Rank, Ltd., nd later from Henry Simon, Ltd., we

Today is the 40th anniversary of the Duramin company, and throughout that period Mr. Oglethorpe has been managing director. They specialize exclusively in light-alloy bodywork, and now have two factories, one at Ruislip, Middx, and the other at Lydney. Glos.

produced our first bulk-flour transporter in 1951.

A typical recent delivery based on a Foden eight-wheeled chassis has,a complete air-fluidizing system by which the aerated flour is fed into a rotary seal at the rear, through which compressed air delivers the flour into bins at a biscuit factory, or bakery, at a rate of about 20 tons an hour.

An air filter is mounted on the front bulkhead above the cab, and is cleaned after each delivery. This type of vehicle can legally carry 151 tons.

Fuller's Earth is another load being carried in bulk, and in the case of a vehicle supplied to the Fuller's Earth Union, Ltd., the air conveyor carries the load to a central position at the rear by means of cross ducts, and by connecting up to a 6-in, suction line the load is elevated some 50-60 ft. into a storage bin. Great care has had to be taken to ensure a highly efficient vacuum release in the body, otherwise serious damage could occur. A load of 14+ tons can be discharged in about 20 minutes.

Hydrated lime is being hauled in vehicles similar to those supplied for carrying flour. It is being used by the lime division of Imperial Chemical Industries, Ltd., at Buxton. The vehicle carries two compressor units, one for the air-conveyor troughs, and the other for elevating the load through Simon blowing seals.

We have supplied many hopper-type vehicles for carrying wheat. A typical example is for J. Rank, Ltd. It is self-discharging through two underfloor hoppers, and can carry 16 tons. Delivery through gratings in the mill floor takes about 10 minutes.

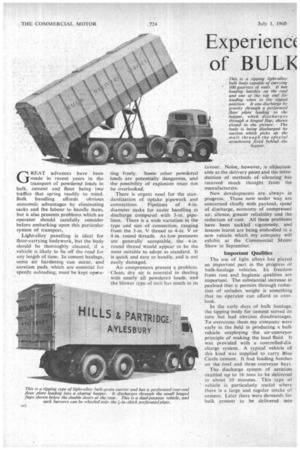

Another -rigid eight-wheeler for handling wheat has been supplied to Hills and Partridge, Ltd. It is a tipper. The rear end of the floor plate is perforated and leads to a cross hopper. Two small hinged doors below the floor at the .rear are opened, and the wheat is emptied through them into a grating in the ground.

The advantage of this vehicle is that it has a flat floor and sack barrows can be wheeled over the perforated section of the -'-in.-thick plate at the rear.

Important new develop

me ts are taking place in the

ha dling of malt. In this instance the big cst problems are at the receiving pot. A tipping vehicle we have Wilt ca carry 100 qr. of malt. It can be lea ed through three hatches in the ro or, when tipped, can take. on its Joa i through a small hatch at the forwad edge of the roof.

perforated plate is fitted across the rear, flush with the floor, and the ma t passes through the holes in it ints a hopper below. From the hopper the malt can be dropped at a contro led rate into a grating in the grs nd, Or on to a conveyor. Ahernatt ely unloading can be by suction. To prevent any vacuum that might be ca sed in the body, two special flaps ar fitted in the front bulkhead.

Handling Flour y company are the sole manufaetur rs of the Bulkmobile vehicle

keted by F. G. Smith Motors, Ltd. A ong Vehicles of this type which have be n built is one supplied to Spillers, Lt., to carry flour. It is an eight

wh tipper and has a dual purpose in that it can carry bagged loads as we l as bulk.

hen used as a bulk transporter, a cross-worm feeder driven by an hydraulic motor is -fitted at the rear. The flour is fed into a rotary seal be ow the floor, and a compressor bl ws it up into storage. The vehicle can also carry bulk wheat and deliver by tipping through an aperture in the tailboard. The crossworm feeder would be removed for this. When transporting flour or fine powder, a patented cross-air flow conveyor can be fitted below floor level in place of the cross-worm feeder.

Another Bulkmobile supplied to J. Bibby and Sons, Ltd., can carry different animal feeding stuffs in six COMpartments. By releasing catches beneath the body, the partitions which separate the compartments can swing on their top hinges towards the rear during tipping, and the load can then be fed by the cross-worm feeder into a rotary seal below the floor. The air compressor mounted on the chassis allows each variety of feeding stuff in turn to be elevated and delivered into separate storage bins.

Commodities such as pellets, crumbs and meal are easily handled, but cubes are more difficult and special attention has to be paid to prevent them from crumbling.

Two Varieties

Thos. Hedley and Sons, Ltd., have an articulated outfit for special powdered loads, two varieties of which can be carried at the same time. The body has a central partition and discharges through two hoppers. Delivery is by suction, the system being connected up by running bogies underneath the vehicle and making adjustments to the two outlets.

Powdered toads do not run freely. It is i.lways necessary for the hatches to be open and for the load to be paddled down manually to complete discharge.