HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

CCONTRIBUTIONS are invited for this page from %"fleet managers, drivers, garage foremen, and mechanics, works staff and draughtsmen, and will be paid for on a generous scale. Every system, make ami type of commercial motor vehicle is being dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle.

It often happens that even a normal practice, or a practice peculiar to a particular type of vehicle, is not generally known. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, dealing with letters from our driver and mechanic readers. Communications should be addressed to "The Editor, The Commercial Motor, 7-15, Rosebery Avenue, London, E.C.1."

465.—What to do if Wear Occurs in a Traction-engine Steering Gear.

The chain type of steering gear employed extensively for steam tractor and, until fairly recently, for almost all types of steam wagon, has a chain drum which is actuated by a worm and wheel. After considerable work the worm wheel becomes worn and causes slack steering and, owing to the fact that the wear is mostly confined to two or three teeth as the axle is seldom locked over to any great extent, there is no way of taking it up, for if the•worm be let deeper into mesh it jams on the unworn teeth when a large lock is necessitated.

However, there is no reason to purchase a new wheel if this proves to be the case, as, by simply removing the steering chains and altering their position on the drum or barrel, an entirely new portion of the wheel will come into mesh with the worm and the wearing life of the gear will be doubled. In fact, this alteration can be effected more than once, each time giving a new lease of life to the gear.

466.—A Simple and Effective Method of Removing Boiler Scale.

In the locomotive type boilers of steam wagons, a weekly or fortnightly. wash out is almost invariably given, but this does not prevent a gradual scaling up of the tubes and the internal surfaces of the boiler which are in contact with the water. The effect of scale in boilers of this description is too well-known to need further comment.

There are several ways of removing it independently of boiler fluids or of going to the expense of drawing the tubes and scraping them and the inside surfaces, and good results can be obtained on boilers with the scale on the tubes and plates about ale in. thick.

The boiler should be thoroughly washed out in the ordinary manner, and all mud plugs returned. It can then be filled with water until the latter just shows in the gauge, the safety valves disconnected, and one of the valves taken out to allow extra water to be added as required.

A fire should then be lighted in the ordinary way, 842

just sufficient fuel being used to keep the water boiling at atmospheric pressure. A bucket of this water should be drawn off and about 7 lb. of good washing soda dissolved in it. The mixture may then be poured down the safety valve through a funnel, and the fire regulated by the damper to keep the water boiling gently until it just recedes from the gauge glass. This operation must be repeated until about 20 lb. of soda have been used and the water kept boiling for six or seven hours, the steam escaping to atmosphere through the safety-valve column.

The boiler may now be cooled down with the sodawater in, and the mixture run off in the morning through the blow-down cock, after which the boiler may be filled up to the working level with fresh water, the safety valves coupled up and the fire lighted in the ordinary manner for the day's work.

The effect of this procedure is not to dissolve the scale but to loosen it, and it gradually falls off and can be washed out in the ordinary course without further trouble.

467.— Preventing the Breakage of Cross-stressed Bolts.

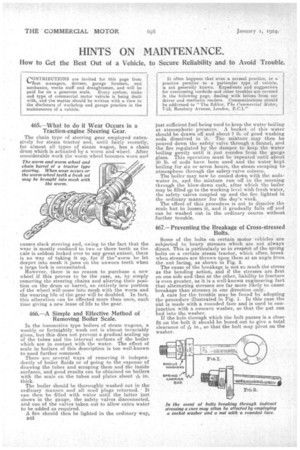

Some of the bolts on certain motor vehicles are subjected to heavy stresses which are not always direct. This is particularly so in respect of the spring bolts on a certain steam tractor, which often break when stresses are thrown Upon them at an angle from. the nut facing, as shown in Fig. 2.

The cause of the breakage is not so much the stress as the bending action, and if the stresses are first on one side and then at the other, liability to fracture is even greater, as it is a well-known engineering fact that alternating stresses are far more likely to cause breakage than stresses in one direction only. A cure for the trouble may be found by adopting the procedure illustrated in Fig. 1. In this case the nnt is made with a rounded face and is used in -conjunction with a conc,s,ve washer, so that the nut can bed into the washer.

If the hole through which the bolt passes is a close fit on the bolt it should be bored, out to give a total clearance of in., so that the bolt may pivot on the washer.