Tar Transport at Even Temperature

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

IN an article appearing in our special Goads Vehicle and Haulage Number published in May last we surveyed the subject of tank wagons for liquid loads and made it clear that increasing pse was likely to be found for such vehicles in those spheres of transport where bulk supplies can be dealt with. There is little doubt that, in some directions, the ultimate development of tanker

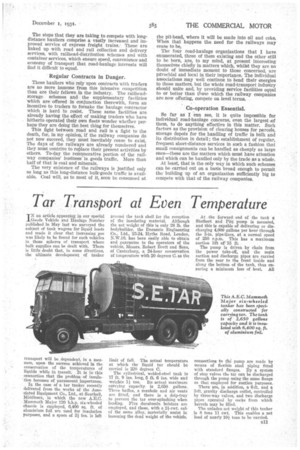

transport will be .dependent, in a measure, upon the success achieved in the conservation of the temperatures of liquids while in transit. It is in this connection that the problem of insulation becomes of paramount importance. In the ease of a tar tanker recently delivered from the works of the Associated Equipment Co., Ltd., at Southall, Middlesex, in which the new A.E.C. Mammoth Major 120 b.h.p. six-wheeled chassis is employed, 6,400 sq. ft. of aluminium foil are used for insulation purposes, and a space of 31 ins. is left around the tank shell for the reception of the insulating material. Although the net weight of this is only 28 lb. the bodybuilder, the Duramin Engineering Co., Ltd., 22-24, Hythe Road, London, NAVA°, has been easily able to obtain and guarantee to the operators of the vehicle, Messrs. Robert Brett and Sons, of Canterbury, a 24-hour conservation of temperature with 20 degrees C. as the limit of fall. The actual temperature at which the liquid tar should be carried is 220 degree C.

The cylindrical, welded-steel tank is 17 ft. 9 ins. long, 5 ft. 6 ins, wide and weights 11 ton. Its actual maximum carrying capacity. is 2,650 gallons.. Three baffles, a manhole and air vents are fitted, and there is a drip-tray to prevent the tar over-splashing when loading. rive duraltimin bolsters are employed, and these, with a 2i-cwt. cab of the same alloy, materially assist in lessening the dead weight of the vehicle.

At the forward end of the tank a Stothert and Pitt pump is mounted, and this is capable of delivering or discharging 4,000 gallons per hour through the 3-in, pipe-lines, at a normal speed of 250 r.p.m. This has a maximum suction lift or 15 ft.

The pump is driven by chain from the power take-off, and the main suction and discharge pipes are carried from the rear to the front inside and along the bottom of the tank, thus ensuring a minimum loss of heat. All connections to the pump are made by means of flexible steel piping fitted with standard flanges. By a system of stop valves the tar can be discharged through the pump using the same flange as that employed for suction purposes.

There are, in addition, a 6-ft. and a 3-ft. gravity discharge outlet, controlled by three-way valves, and two discharge pipes operated by cocks from which

barrels may be filled. ' The unladen net weight of this tanker is 8 tons 11 cwt. This enables a net load of nearly 101 tons to be carried.