PRACTICAL ASPECTS OF \ N BODY CONSTRUCTION

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

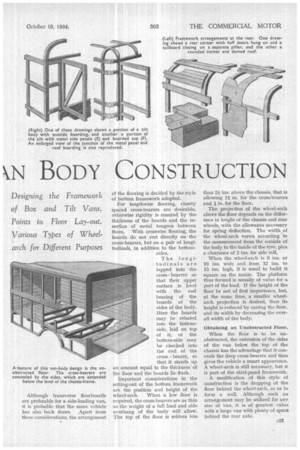

• Designing the Framework of Box and Tilt Vans. Points in Floor Lay-out. Various Types of Wheelarch for Different Purposes THERE are two leading types of covered body for goods vehicles, one being the box and the other the tilt pattern. The boxvan may be of a severe rectangular design, or made more attractive by means of curved side and end panels and rounded corners,. or the outline may approach the streamline form. With the boxvan, the side and roof framework are joined by a top rave, but this rail is omitted in the tilt van and, instead of the standards and hoopsticks of the boxvan, there are hoops which form a continuous arch from one side of the body to the other.

Dealing with Bent Wood Hoops.

These bent wood hoops are usually framed-in at the waist level, where they are lapped to the standards of the lower part of the body, so that the side framework is continued to the bottom. If the hoop be the full height of the body, then, even with a small van, the timber required is at least 15 ft. long, in order to allow for twice the height, as well as the width of the body.

Many tilt vans, however, are wider at the waist than at the floor and there is an overhanging middle rave. In this instance the bent hoops must terminate at the waist. The overhanging rave is notched for the foot of the hoop, and it is set back an amount equal to the thickness of the tilt boarding, so that this may be flush with the outside of the rail.

When the sides of the tilt are flush with the lower part of the body, the waist rail is lapped-in with its upper surface projecting beyond the hoop and forming a bearing for the bottom board of the tilt. In each case, the junction between the board and the rave is covered with a wide moulding.

If there be a metal panel below the waist, the lower edge of the middle rave is recessed for it, or with an overhanging rave it may be grooved in on the underside.

A lightweight tilt consists of bent hoops and lengthwise battens, which support a fixed or loose waterproof sheet. Otherwise, the tilt is close-boarded on the outside and covered with a waterproof duck cloth bedded in paint, apart from its .subsequent outside coats of paint.

The boarded tilt, although heavier, has the advantage that it is stronger and keeps its shape better than does a sheet supported on a skeleton framework, especially if it be stiffened at the rear with wide pillars and a deep top rail. Weight may be saved, however, by discarding the conventional outside boarding and using in its place an aluminium panel.

This panel may cover the tilt entirely, or only the sides, with the centre and flat portion of the roof boarded in the usual manner. If this composite form of construction be adopted, a roof rail is re

quired with a deeper recess on one side than on the other, so that an 12-gauge aluminium panel may lie flush with a 4-in, roof board. For the same reason, the upper surface of

the hoop is higher under the panel than it is under the board_ Van floors are laid either lengthwise or crosswise. When the boards are longitudinal and the van is loaded from the rear, on most occasions the goods will be moved over the floor boards parallel with the direction of the grain of the wood. Moreover, should there be any irregularity in the floor, owing to the edge of a board projecting above its neighbour; this ledge would not offer the same amount of obstruction as with crosswise boards.

Although transverse floorboards are preferable for a side-loading van, it is probable that the same vehicle has also back doors. Apart from these considerations, the arrangement of the flooring is decided by the style of bottom framework adopted.

For lengthwise flooring, closely spaced cross-bearers are desirable, otherwise rigidity is ensured by the thickness of the boards and the insertion of metal tongues between them. With crosswise flooring, the boards do not rest directly on the cross-bearers, but on a pair of longitudinals, in addition to the bottom sides.

The longitudinals are lapped into the cross-bearers so that their upper surface is level with the end bearing of the boards at the sides of the body. Here the boards may be rebated into the bottomside, laid on top of it, or the bottom-side may be checked into the end of the cross bearer, so that it stands up an amount equal to the thickness of the floor and the boards lie flush.

Important considerations in the setting-out of the bottom framework are the position and height of the wheel-arch. When a low floor is required, the cross-bearers are as thin as the weight of a full load and side overhang of the body will allow. The top of the floor is seldom less than 2i. ins, above the chassis, that is allowing 14 in. for the cross-bearers and in. for the floor.

The projection of the wheel-arch above the floor depends on the difference in height of the chassis and rear wheels, with the allowance necessary for spring deflection. The width of the wheel-arch varies according to the measurement from the outside of the body to the inside of the tyre, plus a clearance of 2 ins, for side roll.

When the wheel-arch is 9 ins. or 10 ins, wide and from 12 ins. to 15 ins. high, it is usual to build it square on the inside. The platform thus formed is usually of value for a part of the load. If the height of the floor be not of first importance, but, at the same time, a smaller wheelarch projection is desired, ' then its height is reduced by raising the floor, and its width by decreasing the overall width of the body.

Obtaining an Unobstructed Floor.

When the floor is to be unobstructed, the extension of the sides of the van below the top of the chassis has the advantage that it conceals the deep cross:bearers and thus gives the vehicle a smart appearance. A wheel-arch is still necessary, but it is part of the skirt-panel framework.

A modification of this style of construction is the dropping of the floor behind the wheel-arch, so as to form a well. Although such an arrangement may be utilized for any size of van, it is of greatest value with a large van with plenty of space behind the rear axle.