MADE FOR MILEAGE

Page 56

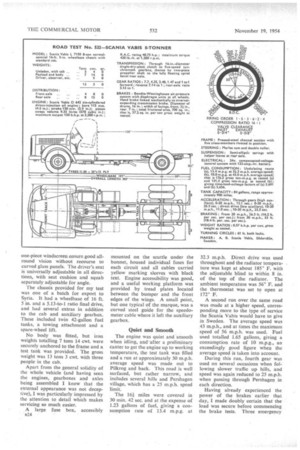

Page 57

Page 58

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

by John F. Moon, A.M.I.R.T.E.

1 T may not be generally realized that A.B. Scania Vabis, of Sodertalje, Sweden, have been manufacturing high-quality vehicles for nearly 60 years, since the days when each chassis was almost entirely built by an individual craftsman. A similar standard of workmanship is still continued to this day, and recently I was afforded the opportunity IA testing an example of the latest series of chassis to come from this concern, the L 7150 8-ton normal-control four-wheeler.

The L 71 vehicles are of an exceptionally high standard in respect of performance and reliability, and are not only high-speed, longdistance load carriers, but also suitable for timber hauling and general construction work. The time-loadmileage figure of 5,656 which was obtained after a fast run over a hilly route is proof of the high-speed economy standard set by Scania Vabis, and even under such con n22 ditions the 150 b.h.p. oil engine was working with a large margin of reserve power.

The power unit of the L 71 range is the Scania Vabis D 642 six cylindered direct-injection engine. Its 150 b.h.p. is developed at the governed speed of 2,200 r.p.m., and the maximum torque output of 420 lb.-ft. occurs.at 1,200 r.p.m, The cast-iron cylinder block and crank case unit carries wet centrifugal-cast cylinder liners, which have a bore of 115 mm., the seals between the block and the liners being rubber rings. The crankshaft is an alloy-steel stamping and, before assembly into the engine, all journals are burnished by hand to reduce initial friction and eliminate the risk of small particles entering the oil flow and damaging other bearings.

The main 'aridbig-end bearings arc steel-backed lead-indium-coated leadbronze bearings of the skip type and the crankshaft carries a torsional vibration damper. Three compression and two oil-control rings are fitted to each cavity-head aluminiumalloy piston, and the top rings are chromium-plated. The pistons, which have a stroke of 150 mm., have fully floating case-hardened steel gudgeon pins.

There are three identical cylinder: heads, each carrying two injector nozzles. Stellite-faced valve seats • are shrunk into place, and inlet and exhaust valves are also Stellite-faced,' with chromium-plated stems. The inlet valves are not shrouded, sufficient turbulence being provided by the design of the inlet ports and the piston cavities. The exhaust manifold is in three Sections to allow for expansion and the single inlet manifold carries two oil-bath air cleaners mounted at the front of the engine between the radiator block and the valve-gear cover.

C.A.V. fuel-injection equipment is used, with an N-type pneumatically governed pump gear driven through an idler from the front of the crankshaft, and four-hole injector nozzles. A gear-type pump, driven from the crankshaft, provides positive lubrication to all bearings, with an intermit tent feed to the rocker gear. A triangulated twin V-belt drives the Bosch 24v. dynamo and the fan, which is adjustable about an eccen tric shaft. The centrifugal water pump is shaft driven in tandem with the dynamo.

A 16-in.-diameter single-dry-plate clutch, with solid centre plate, transfers the torque to the large five-speed direct-top gearbox. This has baulkring synchromesh engagement and helical gearing for all except first and reverse ratios, which have straightcut teeth. The mainshaft gears rotate on bronze bushes and are positively lubricated by rotating-plunger oil pump. A further detail worthy of note is the provision of a magnetic oil filter at the drain plug.

The gearbox is unit-mounted with the engine, the assembly being supported at four points on rubber blocks, with a fifth pad underneath the gearbox to absorb torque reaction and steady the unit.

Specified as optional equipment, but fitted to the chassis tested, is a two-speed constant-mesh auxiliary box. This is mounted on rubber midway in the transmission line and provides a direct drive and a 1.47 to 1 reduction. A metal and rubber torsional vibration damper is fitted to the input shaft of the auxiliary box and this, in conjunction with a Layrub joint at the main-gearbox end of the propeller shaft, is effective in smoothing out the transmission.

The fully floating rear axle has a 16-in.-diameter spiral-bevel crown wheel and a proportionately large pinion. The gearing is mounted in a massive pressed-steel banjo casing and the half-shafts are splined into the hubs to increase torque capacity.

The chassis frame, which is made entirely by Scania Vabis, is a pressed-steel riveted assembly with 91-in.-deep side members and a flat upper flange, and having five channel-section cross-members.

Standard braking equipment on

the L 71 is the Bettdix-Westinghouse air system, but Lockheed hydraulic brakes with a Bendix-Hydrovae booster are available. The rear brakes have a frictional area of 466 sq. in., the facings being 7 in. wide. The twin-cylindered compressor is belt-driven from the front of the, . crankshaft and there are two reservoir tanks.

The brake pedal acts directly on the brake valve and the maximum operating pressure is 105 p.s.i.

Diaphragm units are fitted to all• wheels, the rear units being bolted to the axle casing and acting through a floating lever and shafts. An alcohol evaporator, mounted on the engine bulkhead, is Connected to the inlet side of the compressor to prevent the system freezing because of condensation.

The hand-brake lever is linked to a 12-in.-diameter internal-expanding drum brake behind the auxiliary box, or behind the main gearbox when no auxiliary is fitted.

An Oskarsham composite cab is used by Scania Vabis when a cab is ordered, but is not fitted as standard equipment. This cab, which seats three persons comfortably, has a-timber frame with a stressed inner skin of plywood, and pressed-steel outer panels. Porous insulating material is interposed between the two skins. The two wide rear windows and one-piece windscreen ensure good allround vision without recourse to curved glass panels. The driver's seat is universally adjustable in all directions, with seat cushion and squab separately adjustable for angle.

The chassis provided for my test was one of a batch for export to Syria. It had a wheelbase of 16 ft. 5 in. and a 5.13-to-1 ratio final drive, and had several extras in addition to the cab and auxiliary gearbox. These included twin 42-gallon fuel tanks, a towing attachment and a spare-wheel lift.

No body was fitted, but iron weights totalling 7 tons 14 cwt. were securely anchored to the frame and a test tank was provided. The gross weight was 13 tons 3 cwt. with three people in the cab.

Apart from the general solidity of the whole vehicle (and having seen the engines, gearboxes and axles being assembled I knew that the external appearance was not deceptive), I was particularly impressed by the attention to detail which makes servicing so much easier.

A large fuse box, accessibly B24 mounted on the scuttle under the bonnet, housed individual fuses for each circuit and all cables carried yellow marking sleeves with black text. Engine accessibility was good, and a useful working platform was provided by tread plates located between the bumper and the front edges of the wings. A small point, but one typical of the marque, was a curved steel guide for the speedometer cable where it left the auxiliary gearbox.

Quiet and Smooth

The engine was quiet and smooth when idling, and' after a preliminary canter to get the engine up to working temperature, the test tank was filled and a run at approximately 30 m.p.h. average speed was made out to Pilkrog and back. This road is well surfaced, but rather narrow, and includes several hills and Pershagen village, which has a 25 m.p.h. speed limit.

The l6i miles were covered in 30 min. 42 sec. and at the expense of 1.21 gallons of fuel, giving a consumption rate of 13.4 m.p.g. at

32.3 m.p.h. Direct drive was used throughout and the radiator temperature was kept at about 185° F. with the adjustable blind to within 8 in. of the top of the radiator. The ambient temperature was 56° F. and the thermostat was set to open at 172° F.

A second run over the same road was made at a higher speed, corresponding more to the type of service the Scania Vabis would have to give in Sweden. The average speed was 43 m.p.h., and at times the maximum speed of 56 m.p.h. was used. Fuel used totalled 1.65 gallons, giving a consumption rate of 10 m.p.g., an exceedingly good figure when the average speed is taken into account.

During this run, fourth gear was used on several occasions when following slower traffic up hills, and speed was again reduced to 25 m.p.h. when passing through Pershagen in each direction.

Having already experienced the power of the brakes earlier that day, I made doubly certain that the load was secure before commencing the brake tests. Three emergency

applications from 20 m.p.h. produced an average stopping distance of 26-1 ft. and from 30 mph. the distance was 53 ft., giving an average retardation of 0.57 g. The wheels had just started to lock each time the chassis came to rest and it is possible that had the road been completely dry, the figures would have been improved slightly.

With the engine stationary, the reservoirs •hold sufficient pressure for five full applications before the pressure drops to 62 p.s.i., at which pressure a warning buzzer sounds.

Smart Acceleration

The acceleration figures were no less impressive than the braking figures. Because of the auxiliary box, several sets of readings were taken with either high or low ratios engaged. From a standing start and using second, third and fourth gears, the fastest time was recorded with the high ratio of the auxiliary box, but the difference was only slight when using low ratio and the four highest ratios of the main box.

Similarly, two sets of figures were obtained for the direct-drive test, and although the engine protested a little whets pulling away in direct drive, it smoothed out at about 14 m.p.h. In low ratio the acceleration from 10 -m.p.h. was good, as is evidenced by the time of 23.5 sec. taken to reach 30 m.p.h. The quick gear changes made possible by the synchromesh gearbox, combined with the high engine torque, yielded an acceleration rate well above average for this type of vehicle.

From Rest on 1 in 5.8 Final tests were made on two nearby. hills, the steepest of these being Sankt Ragnhildsgatan in Soderthije, which has a maximum gradient of 1 in 5.8. The L 71 scaled this short gradient in second gear high, but when stopped at the steepest section it was necessary to engage low ratio in the auxiliary box to pull away again. No excessive pressure was needed on the hand-brake lever to hold the chassis, and the clutch was smooth during the take-up of power.

Tvetabacken Hill is about half .a mile long, with an average gradient of 1 in 8.75, and required the use of second gear high. With the blind lowered 8 in from its highest position the temperature rose to 190 F. after three climbs, but when the blind was completely lowered the temperature fell and remained at 150' F.

This indicates that the cooling system is efficient enough for opera tion in hot climates while still working satisfactorily in cold Cowl' tries. During the climb, while pulling hard in secondgear, no exhaust smoke was observable, which showed that complete combustion had been obtained.

was impressed by the lightness of the controls and the quietness of the power unit. The steering was good at high speeds, but a little heavy by British standards when manceuvring in a confined space.

With a front-axle loading of nearly 4i tons, however, the steering effort required was not excessive, and the 22-in.-diameter two-spoked steering wheel enabled a good leverage to be obtained. The good steering lock was useful in tight corners.