T HE 36-ft.-long, 8-ft,in. wide publicservice vehicle was the sole subject of Mr.

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

McHugh's paper. He based J. McHugh on his discussion on the assumption that the public would turn more and more to the single-deck transit bus for short-haul transport in the centres of towns and cities.

This necessitated some rethinking on the part of the bus engineer, he said, especially if new passengers were to be attracted away from motorcars, and fast loading and unloading of vehicles was to be a desirable concept.

Elderly people were forsaking buses because of alighting and boarding difficulties with orthodox buses. Younger people preferred cars because of the unattractive decor and general finish of some of the older p.s.v.s.

Furthermore. he went on, there was a growing demand for reduction in the cost of operation, and in the purchase cost of new vehicles. The answer was a complete revision of design thinking in connection with vehicle weights. If tare weight could be reduced, purchase and operation costs might also he brought down.

Mr. McHugh's concept was, therefore, virtually dictated by the weight consideration, he said.

The vehicle he had in mind would weigh 31 tons, with a full tank of fuel. Within the 36-ft. x 8-ft. 2+-in. dimensions, it would have seats for 48 passengers and a maximum load, including standees, of 75. There would be a single forward entrance. Maximum gross vehicle weight would be 81 tons. The power unit would be a six-cylindered oil engine developing 125 b.h.p. at 2,400 r.p.m. Four-speed fully automatic transmission would have torque converter input combined with a direct-drive lock-up automatic clutch.

Mr. McHugh's design called for a glass-fibre body, integrally constructed, of a double-skinned design with reinforcement between the skins. Plastics frames would be used for the transverse seat. Only one step would be necessary for the entrance and rear exit, if provided, with maximum floor height of 18 in.

Use of a single longitudinal chassis member and integral body would provide a full integrated structure which still allowed for removal of the body.

A maximum diameter of 30 in. was envisaged for the tyres, to be fitted on 15-in. wheels. The front axle loading would be 2+ tons and the rear 5+ tons on twin tyres.

Front and rear brakes would be discs, hydraulically operated with pneumatic assistance. The rear callipers

CHANGED CONCEPTS FOR TOWN BUSES

would incorporate mechanical actuation for the handbrake. Full air suspension would be used at the front of the single air-chamber type, and dual-chamber at the rear. The front axle would be pivoted from rubberized locations forward 'of the axle. By combining a rigid beam axle and trailing-arm connections, a limited-roll stabilizer effect would be achieved in combination with a forwardlocation for the rear axle. Double-reduction final drive would be used, with 1.3-to-1 spiral bevel gears and a 4-to-1 helical gear.

A transversely mounted rear engine was envisaged, located under the rear seat. Integral mounting would be provided for the automatic transmission. A 24v. alternator would be used. The engine cooling fan would force air through transverse radiators incorporated in the body structure, the heated air either being used for heating the interior of the bus or being ejected at the rear. Moulded heating ducting would be built into the body. Light fixtures, pattrasses and wiring ducts would also be built-in.

Individual one-piece plastics seats and back supports were envisaged, being demountable from the seat frames.

Light-alloy one-piece wheels and hubs would be utilized, with provision for demountable rims. A further weight reduction might be achieved by replacing ferrous castings or forgings with light-alloy pressure die-castings, Tests, said Mr. McHugh, had shown that such a Vehicle achieved over 13 m.p.g. fully laden at five stops per mile on a level road. At a continuous 30 m.p.h. it returned more than 23 m.p.g.

A minimum service life of 10 years could be expected of such a vehicle, he said, but it might prove to last much longer. If what Mr. McHugh described as " exotic " materials (such as titanium alloys, lightweight plastics, or magnesium alloys) were used where structurally possible, further weight reductions were feasible. If the passenger capacity were limited to 50, a smaller engine might be used.

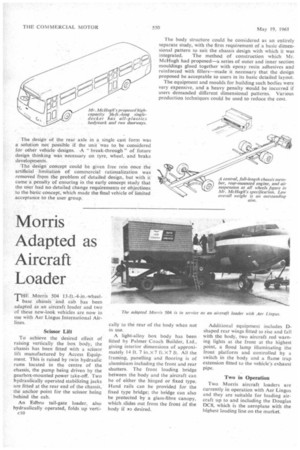

For a long period the economics of production have dictated the types of vehicle available to the industry. But the time would shortly arrive when the concept of a bus such as Mr. McHugh had specified would be justified. The vehicle would be basically a simple chassis with an inte grated complete body structure. The "spinal chord" chassis would take all the suspension loads and the engine and gearbox would be installed on a chassis structural member. Steering and controls would be mounted on a forward transverse member. The design of the rear axle in a single cast form was a solution not possible if the unit was to be considered for other vehicle designs. " break-through" of future design thinking was necessary on tyre, wheel, and brake developments.

The design concept could be given free rein once the artificial limitation of commercial rationalization was removed from the problem of detailed design, but with it came a penalty of ensuring in the early concept study that the user had no detailed change requirements or objections to the basic concept, which made the final vehicle of limited acceptance to the user group. The body structure could be considered as an entirely separate study, with the firm requirement of a basic dimensional pattern to suit the chassis design with which it was integrated. The method of construction which Mr. McHugh had proposed—a series of outer and inner section mouldings glued together with epoxy resin adhesives and reinforced with fillers—made it necessary that the design proposed be acceptable to users in its basic detailed layout.

The equipment and moulds for building such bodies were very expensive, and a heavy penalty would be incurred if users demanded different dimensional patterns. Various production techniques could be used to reduce the cost.