New Features in All-metal Bodywork

Page 57

If you've noticed an error in this article please click here to report it so we can fix it.

riONSIDERABLE aCtivity prevails

in the bodybuilding shops of E. J. Newns, Ltd., of Portsmouth Road, Thames Ditton, Surrey, where many types of body are produced, primary attention being given to all-metal construction. Mr. E. 3% Newns, the managing director of the company, has for many years been concerned with allmetal bodies and he has eVolved a successful pattern, several modifidations to which have recently been made.

The cranked angle-steel bottom members, which carry wood floor bearers, are bolted to the chassis and a layer of felt is interposed as an insulator. Hand-beaten-steel side pillars are

riveted to the cross-members and they are securely flitch-pia-bed to the floor bearers, these plates fitling into the

uprights. • The main side pangs are Axed chiefly to the waist-rail, although two copper rivets are used to secure the panels to each standing pillar.. It is claimed that, by . this arrangement, sideways flexing of the body is permitted, thus allowing shocks to be absorbed and, at the same time, minimizing the risk of the panels splitting at their inost vulnerable points. Further to ensure flexibility the outside shell of the body is not fixed to the framework between the waist and the cant-rail level. The cantpanel is welded in one piece from front to back.

Three angle bearers stretch across the body and support the weight of the luggage compartment, several patterns of which are constructed. In future it is proposed to fit stainless-steel waistbands to Newns coach bodies.

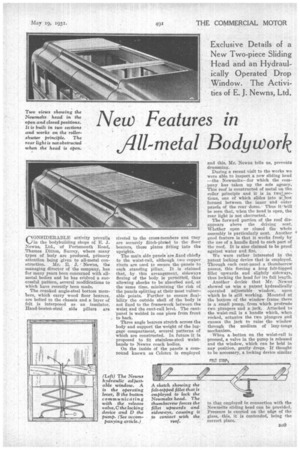

On the inside of the panels a compound known as Celotex is employed and this, Mr. Newns tells us, prevents drumming. During a recent visit to the works we were able to inspect a new sliding head —the Newmelts—for which the company has taken up the sole agency. This roof is constructed of metal on the roller principle and it is in twojseetions, one of which slides into a. box formed between the inner and miter panels of the rear dome.Thus be seen that, when the head is open, the rear light is not obstructed.

The forward portion of the roof disappears above the driving seat. Whether open or closed the whole assembly is particularly neat. Another good feature is that it works freely by the use of a handle fixed to each part of the roof. It is also claimed to be proof against water and Ere.

We were rather interested in the patent locking device that is employed. Through each cant-panel a thumbscrew passes, this forcing a long felt-topped fillet upwards and slightly sideways, thus locking the head for its full length.

Another device that Mr. Newns showed us was a patent hydraulically operated adjustable window, upon which he is still working. Mounted at the bottom of the window frame there is a small pump, from which protrude two plungers and a jack. Attached to the waist-rail is a handle which, when rocked, actuates the two plungers and causes the jack to raise the window through the medium of lazy-tongs mechanism.

When a button on the waist-rail is pressed, a valve in the pump is released and the window, which can be held in any position, gently drops. If thought to be necessary, a locking device similar

rat