Mechanical "Mannequins" Take the Floor

Page 42

Page 43

Page 44

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

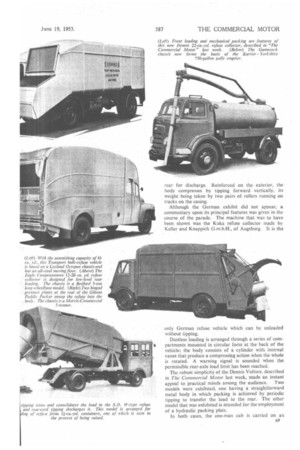

(Right) The new Dennis underfloor-mined refuse collector has crew seats at the rear which recede into the body sides when not in use or when dis charging the load.

FOR the transport operator, the highlight of last week's International Conference on Public Cleansing, at Edinburgh, was Wednesday's demonstration, when, as is usual at the British gatherings, there was a "mannequin parade" in which over 70 vehicles each made a-brief appearance in the arena while the manufacturers' representatives expounded the points of their products. This was an impressive exhibition and those who criticize lecal authorities for their expenditure on modern appliances might have spent a profitable morning in weighing up the value of the efficiency that can be set off against capital costs.

Those who have watched successive annual parades appreciate the steady, if somewhat stately, progress that has been made in cleansing-vehicle design, as well as the manner in which makers have, in later years, evolved designs that save labour and are increasingly hygienic. All this, however, the general public tends rather to take for granted.

The weather was unkind on Wednesday, for the first time during the conference, and so the organizers' choice of Edinburgh's Waverley Market as the venue was justified despite the accompanying gloom and the restricted space, which meant that only in a few cases could the working of the machines be adequately demonstrated.

Paradoxically, the greatest interest and publicity fell to those vehicles that did not arrive, especially to the Johnston appliances, which were, reported to have disappeared without trace somewhere on the British Railways system. .

Three vehicles were expected from Italy, Germany and Holland, but only the Dutch exhibit appeared, the German being involved in a little individual exhibition at the Dover Customs control. There was a strong British link with the Dutch machine, as the chassis was a forward-control Seddon, assembled in Holland by

Van Twist. , On this was mounted a N.E.T.A.M. collector body which has a three-bin dust-free rear loading compartment that hinges forward when the body is tipped to the rear for discharge. Reinforced on the exterior, the body compresses by tipping forward, vertically, its weight being taken by two pairs of rollers running on tracks on the casing.

Although the German exhibit did not appear, a commentary upon its principal features was given in the course of the parade. The machine that was to have been shown was the Kuka refuse collector made by Keller and ICnappich G.m.b.H., of Augsburg. It is the only German refuse vehicle which can be unloaded without tipping.

Dustless loading is arranged through a series of compartments mounted in circular form at the back of the vehicle; the body consists of a cylinder with internal vanes that produce a compressing action when the whole is rotated. A warning signal is sounded when the permissible rear-axle load limit has been reached.

The robust simplicity of the Dennis Vulture, described in The Commercial Motor last week, made an instant appeal to practical minds among the audience. Two models were exhibited, one having a straightforward metal body in which packing is achieved by periodic tipping to transfer the load to the rear. The other model that was exhibited is intended for the employment of a hydraulic packing plate.

In both cases, the one-man cab is carried on an B9

outrigger, so that the driver has a completely unobstructed view of the road in front and of the loaders working at his side. A Perkins P6V underfloor oil engine is used. Heavy metal doors are located at the rear 3 ft. from the end of the body, the intervening pace providing seats for the loading crew. When tipping is taking place, the seats and arms fold flat behind the doors, so that the movement of the load is uninterrupted.

Bulk Loading

Long specialization in the cleansing field by Shelvoke and Drewry, Ltd., has ensured an interested reception for fresh ideas from this source. Thence comes the S473 bulk-loading design. This provides for the contents of large bins to be projected to the front of the body, the method employed avoiding the use of any additional hydraulic gear or controls.

Containers of up to 11-cu.-yd. capacity are removed from their standings by a simple form of jack lift in which the lifting is performed by the pulling handle. After being wheeled into position at the rear of the S.D. fore-and-aft-tipping collector, the containers are hooked to a special rear door and lifted automatically by the forward tipping action of the body.

The upper part of the rear door has an aperture through which the mouth of the bin enters as the body is lifted, the container then being tipped so that the refuse has the available length of body into which it can fall, this action giving a substantial degree of consolidation. The rear aperture has an effective dustsealing arrangement; the bin mountings are arranged so that in the event of a fracture occurring, it would be impossible for a container to fall. Discharge of the load is by end tipping, the rear doors opening automatically, as in the case of other S.D. fore-and-aft tippers.

Because of the restricted entrance to the market, the

City of Edinburgh's Super Jekta for bulk disposal was among those vehicles which were inspected outside the hall. This comprises a 26-cu.-yd. body on a Leyland Octopus eight-wheeled chassis and is intended for handling the maximum legally permissible weight of dust and clinker, the laden total being 22 tons. Larger bodies of this design, up to 40 cu. yd., can be supplied. The model exhibited was a five-section telescoping body giving hydraulically operated horizontal discharge, and the whole was encased in aluminium panelling to avoid dust emission.

The specialized designs produced by Glover, Webb and Liversidge, Ltd., are always sure of an attentive audience and of particular interest this year was the bulk refuse vehicle produced for Liverpool. This machine may be described as additional evidence of a new line of thought on the subject of refuse disposal and the manufacturers claim it as the largest machine of its kind ever produced.

41.2 Cu. Yd.

Its capacity is 41.2 cu. yd. and the roof is arranged for overhead loading of bulk refuse. Discharge is achieved by a heavy-duty version of the Transport rustproof steel moving floor, which is stated to unload 12 tons of refuse in under two minutes. The vehicle shown was based on a Leyland Octopus chassis.

A Scottish product of note to be seen last week was the Paddle Packer, made by John Gibson and Son, ' Ltd., which was shown on a Morris-Commercial FVS12/5 chassis and provides a capacity of 12-16 cu. yd. with a payload of 51 tons. The loading line is only 3 ft. 2 in. high, the bin being easily tipped into the hopper and the paddles carrying the refuse forward. • Operating hydraulically, the paddle mechanism is robustly constructed and, by the use of cams, the pressure plates are made to present a vertical face when compressing the load. When the refuse is to be emptied, the entire body tips to the rear, the compressing mechanism swinging clear.

A nice touch to show how the old street sweeper has risen in the world is provided by the arrangements for fitting both heater and radio in the cab of the Bedford-Lacre sweepercollector which was first introduced last summer. The latest model is based on the Bedford A4SS 4-ton chassis, thus facilitating the provision of a larger water tank for spraying and increased loading capacity. Longer operating runs can, therefore, be undertaken.

Heavier tyres are fitted, but the turning circle has been decreased. Although the cab appears more capacious, the BedfordLacre is still one-man operated and, with this in mind, certain improvements have been effected in the control position.

The Karrier Gamecock 3-4-ton chassis has provided the basis for several revised models from that factory. There is a full-forward-control machine which replaces the C:K3, and uses the 85 b.h.p. six-cylindered o.h.v. underfloor engine. The all-steel body is fitted with curved sliding covers in three sections and a tail door designed so that each half can swing flush against the side of the vehicle. On the model exhibited there was a seven-seat cab, but a more luxurious three-seat version with rear corner windows and swivelling quarter lights is available.

A 15-cu.-yd. refuse collector, giving a neat form of dustless loading, was also to be seen on the Gamecock chassis. In this case there was a moving floor of rustproof steel slats driven by a two-speed reduction gear. the lower ratio being employed for compressing bulky refuse against the tail doors. Among models now employing the Gamecock chassis is the KarrierYorkshire 750-gallo7 gully-emptier.

Specially featured on Bedford cleansing vehicles with bodies and equipment by the Eagle Engineering Co., Ltd., was the Neville crew cab with accommodation for driver, foreman and four loaders. In order to fit in with the Bedford design, this cab is now readily removable by means of a straight lift, instead of being hinged forward.

A Fordson Thames 7-cu.-yd. refuse collector was shown with the new four-cylindered o.h.v. engine. Another Thames exhibit which found favour with a section of the spectators was a 500-gallon road sprinkler which was on order for Port Sudan. An emergency fire-fighting connection is fitted and two separate lengths of fire hose may be used.

The chassis is a Thames 4-tonner of 128-in. wheelbase, and equipment by the Eagle Engineering Co., Ltd., includes welded all-steel cylindrical tank, single-stage centrifugal pump operated from the power take-off, and two gunmetal sprinkler heads controlled separately from the cab. A suction valve and connection enable the tank to be filled from static supplies.

Although demonstrated on a Bedford 5-ton longwheelbase chassis, the Eagle-Compressmore 12-20-cu.-yd. refuse body is also suitable for use in semi-trailer form. The Compressmore two-section compression plate is suspended from an overhead trolley unit, the barrier plate being operated by a double-acting hydraulic ram. The body superstructure, in this case, is of light pressed-steel sections, with the floor sloping towards the tail so as to reduce the loading line and to provide the greatest possible carrying capacity beneath the loading rail. Discharge is by hydraulic tipping, the tail door being retracted into the roof.

Extensively used in India and elsewhere, the Scammell Scarab 3-ton semi-trailer unit, a 9-cu.-yd. side-loading end-tipping collector, presented an attractive appearance with a trough-shaped body tapering from front to rear for the purpose of easy discharge. •

Emphasis was laid on the valuable work that can be 'performed by the pedestrian-operated orderly trucks which fall into the £.3 tax category. Specimens shown included the Manulectric 1-ton (2-cu.-yd.) unit, and the Electruk. An endeavour to obtain the best of both the electric and the internal-combustion worlds is seen in a new Harbilt truck carrying two bins, each of 1-cu.-yd. capacity.

Co-ordination in the design of the bins and of a parent collecting vehicle provided for rear levers which engaged with lugs on the Harbilt containers, so that the contents were then deposited automatically into the main collector. Afterwards the bins were automatically replaced on the truck. In this way losses of time caused by the need for returning to a disposal point can easily be eliminated.