THE GOODS CHASSIS =0 TO-MORROW

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

To-DAY

IN a recent issue of this journal (June 5.), I reviewed the pros and cons of present-day types of goods vehicle in relation to engine position and its effect upon accessibility and body space. I now propose to submit various layouts of chassis design which would overcome the serious defects I then outlined, and, at the same time, would dissipate many of the other difficulties at present encountered by the operator in connection with running and maintenance.

The proposed arrangements would entail a radical departure from orthodox design, but vehicles built on these lines would, in my opinion, offer many advantages which cannot otherwise be obtained. Indeed, I consider that the need for this revision is more urgent than the majority of manufacturers and designers have so far realized, and that there will eventually be a general demand for such a revolutionary change.

Whilst manufacturers have adhered for so many years to a general layout on the lines of touring-car practice it would now appear that new developments are needed to cater for modern requirements.

It is, in fact, remarkable that so little change has been made in the basic principle of design, and " stagnation" would appear to be the order of the day.

This is equally applicable to detail design, and, as an example, I would point out the

common difficulty of gainingaccess to the batteries for topping up purposes, or of seeing or removing anything from beneath the instrument facia . board. These are only details, but are important.

Manufacturers, naturally, do not wish to make drastic changes, but if the advantages, from a, manufacturing, operating, and maintenance point. of view, accruing from such outweigh those existing at present, then surely a revised policy is warranted, provided, of course, that there is no commercial riSk or interference with production.

132 Traditionally, as a. nation, we are inclined to possess a very conservative outlook on all innovations, but it would appear that the German manufacturers are much less bound by the orthodox than are we in this country. When we consider that at the recent Berlin Show most manufacturers staged vehicles having horizontal engines we see that they realize that the use of this type is the only logical method of overcoming present-day difficulties in rlesign. Many of the younger generation of automobile engineers speak with awe of the horizontal engine, as though it were something to be shunned, but it should be recalled that, with one exception, all the earliest motor vehicles made in this country were so equipped, and that the remarkable results of the early Wolseley and Lanchester cars were obtained with this type of unit. The reason is not hard to seek ; they were based on sound gas-engine practice.

Many people labour under a misapprehension regarding the lubrication of this type and visualize many difficulties. Modern practice, however, proves that with the use of forced feed and the dry-sump system no trouble Whatever is experienced. Incidentally, aeroplane engines, having inverted cylinders, do not experience the slightest trouble from this cause.

It is agreed that with the old splash system, where dippers picked up oil from troughs, trouble naturally ensued, for the bulk of the oil was thrown into that cylinder into which the piston was moving when the big-end was at its lowest position, with consequent over-lubrication, whilst the opposing cylinder suffered , from starvation.

An advantage of the multi-cylindered horizontally opposed engine, which is not always realized, is that for a given number of cylinders it is shorter and lighter than a corresponding engine with the cylinders in line. Moreover, the crankshaft is stiffer and, therefore, there is less torsional vibration.

The horizontal engine has received careful consideration and development in America and has been widely adopted. Among the leading makers of this type are the White company of Cleveland and the Hall-Scott concern.

In incorporating the horizontal engine in my, proposals, I claim that this type is the only remedy for body encroachment and inaccessibility. Accessibility is of the utmost importance in maintenance work, but often receives the least consideration in design.

• Many engineers believe that engine reliability has reached the stage where accessibility may be sacrificed. In my opinion, this outlook is wrong. Regular inspection is the secret of good maintenance, and, if this can easily be accomplished, it will probably save the operator delay and expense by nipping troubles in the bud.

I have endeavoured to aim at the utmost accessibility of both main components and accessories, and to allow for the maximum body-space area.

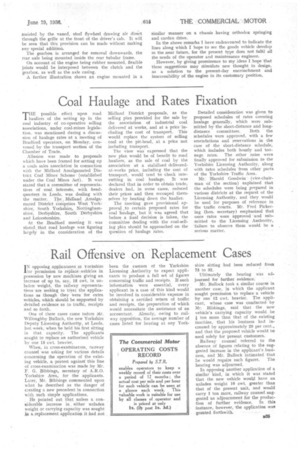

From the illustrations, which are purely schematic and do not represent finality, it will be seen that there are several alternative chassis layouts, although the general scheme of the vehicle is the same in all cases.

It will be noted that, as previously mentioned, the engine in each layout is of the compression-ignition type and either a horizontally opposed or simple multi-cylindered unit. Its adoption is mainly due to its possessing distinct advantages in the saving of headroom, weight, etc., whilst it can be positioned to give a low centre of gravity.

Its location at any point inside the wheelbase gives the utmost accessibility, and is far more get-at-able than when placed in any other position in the chassis. In the simple type the cylinder head may be withdrawn from one side of the chassis, whereas the crankcase cover may be removed on the other.

Efficient Lubricating Arrangement.

Pressure lubrication of the dry-sump type, as used in the White l2-cylindered engine, would be adopted. The actual sump or reservoir is supported over the crankcase, oil being allowed to leak from this reservoir through the oil pump to the crankcase when the engine is standing long enough to get cold.

Accordingly, when the engine is first started, the connecting-rods dip into the oil and give immediate excess lubrication to the pistons and cylinders, but in a short time the two scavenging pumps remove the crankcase oil, and the pressure pump draws lubricant from the reservoir, cleaning it en route.

The gearbox is of the over-speed type and is coupled to the rear axle, either directly or through the medium of a universal coupling. The rear axles may be of the doublereduction, spiral-bevel or worm-driven types. It will be noted that the rear suspension arrangements are shown with either transverse or semi-elliptic springs.

It may be said that the use of transverse springs decreases the stability of the vehicle when rounding corners at high speed, therefore coil springs might be adopted advantageously. This, however, is a matter for decision in the ultimate design.

Various transmission combinations are shown with oscillating axle sleeves, or carclan drive, and, in one case, with a standard axle.

Well-designed Cooling System.

The cooling of the power unit would be assured'by radiators and water pumps, mounted at the forward end of the engine, the radiator being supported on the frame, which position eliminates long lengths of piping, with the consequent risks of leakage.

Fans, driven by twin belts from the crankshaft, are mounted on the radiators and pass air directly through the engine cover to the back.

In connection with the frame, it will be noted that I favour the tubular herring-hone type. This form offers the best means for reducing weight, without sacrificing strength or rigidity, and, in conjunction with steel pressings welded to the main member, forms a structure far stronger than the orthodox type. Ease of welding, at one setting in a fixture, should make for cheap production.

In view of the extra expense which would otherwise be entailed, I have adopted orthodox semi-elliptic springs at the front, these springs being carried from fish-backed pressings, suitably welded and gusseted to the main tube. Shackles are eliminated at the rear of the springs, which run in housings incorporating roller bearings.

The cab illustrated is built of steel pressings, and is mounted' on an extension bolted to the two spring crossmembers. It is detachable, so that, • in the event of accident, replacements or repairs may. be made with ease.

B34

The change-speed control and hand-brake lever are mounted on the main tube, and the rods can pass inside the tube if necessary. The driver's step is placed low to give easy access to the cab and a clear view of the road is obtainable from the driver's seat, which greatly simplifies the handling of the vehicle in traffic.

Incidentally, the freedom of the driving compartment from engine noise and fumes enables the driver to carry out his duties without fatigue and with less physical effort.

Hinged Grille Replaces Usual Radiator., In place of the usual radiator there is a hinged grille which, whilst giving an orthodox appearance to the vehicle, allows air to enter under the footboards and pass through the central frame tube for cooling purposes.

This grille can be swung down to give immediate access to the underside of the facia board, the batteries, wiring, steering gear and controls. The battery supports are adjustable, enabling any type to be accommodated.

Reverting now to the alternative schemes that can be utilized, it will be seen in the left-hand picture in the group that the engine, gearbox and back axle are slung beneath the frame. This construction allows all units to be withdrawn downwards. The rear axle is worm driven, but incorporates a double reduction with helical spur gears, on the lines of the Henschel chassis, This enables the road-wheel centres to be in line with the transmission axis, giving increased clearance beneath the chassis.

The top-centre drawing depicts a more orthodox layout, with the engine mounted above the frame. It will be noted that the section of the frame is of the inverted U shape, which allows for flywheel clearance and eliminates spring brackets, the semi-elliptic springs being mounted inside the channels.

An alternative and unique method would be to mount the power unit amidships in a banjo, formed in the frame, as illustrated on the right. It will be seen that the assembled engine is passed from one side through an opening, having ample clearance. It is slung from the flange and mounted on rubber buffers.

An Air-cooled Crankcase.

When the engine is in position, the pumps, air cleaner, etc., are assembled and the flywheel placed in position. A feature of this layout is that the crankcase is ribbed and mounted internally, in line with the tubular frame member. Air is passed through the latter and impinges upon and passes over the crankcase, thereby cooling the oil and the engine in general. Exit is made finally over the gearbox and back axle and out at the rear. This air stream assisted by the vaned, steel flywheel drawing air direct through the grille at the front of the driver's cab. It will be seen that this provision can be made without making any special addition.

The gearbox is arranged for removal downwards, the rear axle being mounted inside the rear tubular frame.

On account of the engine being rubber mounted, flexible joints would be interposed between the clutch and the gearbox, as well as the axle casing.

A further illustration shows an engine mounted in a similar manner on a chassis having orthodox springing and cardan drive.

In the above remarks I have endeavoured to indicate the lines along which I hope to see the goods vehicle develop in the near future, for the present type does not fen all the needs of the operator and maintenance engineer.

However, by giving prominence to my ideas I hope that these suggestions may stinanlate new thought in design, as a solution to the present-day encroachment and inaccessibility of the engine in its customary position.