ROAD WHEEL RENOVATION.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

Effective Repairs Carried Out by Our Driver and Mechanic Readers.

TWO OF OUR driver readers send us this week descriptions of means 'which they have adoritecl for strengthening or repairing existing wheels of old touring car chassis, which have been converted to use as commercial vehicles.

"Argyll," to whom We award the 15s. prize, may be said, for once in a way, effectively to have carried out the operation of robbing Peter to pay Paul. He tells us that he has an Argyll lorry . which had once been a touring car, and which gave him a lot of trouble owing to the fact that its pneumatic tyres, which were 815 ram. by 105 mm., were too • small for the load—one ton. He was, he says, continually mending punctures, and, as though this were not enough, he eventually discovered that one of the wheels was showing signs of breaking up. He had on his hands a more substantial pair of wheels which had once formed part of a Humber chassis and were already fitted with solid rubber tyres, and he decided to see if it were possible to fit these in place of the ex‘sting ones.

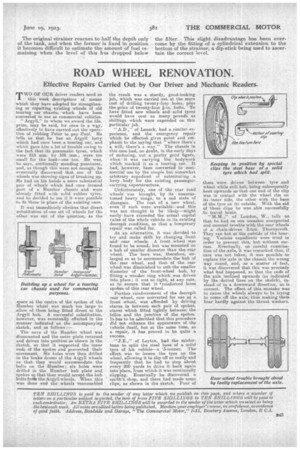

It was immediately obvious that direct substitution of one set of wheels for the other was out of the question, as the • space at the centre of the spokes of the

• Humber wheel was much too large to allow of them being fitted direct to the Argyll hub. A successful substitution, however, was eventually effected in the manner indicated on the accompanying sketch, and as follows—

The nave of the Humber wheel was dismounted and the outer plate reversed and driven into position as shown in the sketch, so that it supported the inner ends of the spokes and prevented their movement. Six holes were then drilled in the brake drums of the Argyll wheels so that they would accommodate the bolts on the Humber; six holes were drilled in the Humber huh plate and spokes so that they would accept the huh bolts from the Argyll wheels. When this was done and the wheels reassembled

the result was a sturdy, good-looking job, which was carried out at the mere cost of drilling twenty-for holes, plus the price of twenty-four I-in. bolts. To have fitted new wheels and solid tyres would have coat as many pounds as shillings which were expended on this particular job.

" A.D.," of Lanark, had a similar experience, and the emergency repair which he effected. gives point and emphasis to the saying that where there's a will, there's a way." The chassis in this case had, DO doubt, in the early days of motoring, cut a pretty good figure, when it was carrying the bodywork which marked it as a touring car. It had, however, been converted to coinmercial use by the simple, hut somewhat arbitrary expedient of substituting a lorryfor the existing passengercarryng superstructure.

Unfortunately, one of the .rear road wheels was brought, by its unaccustomed heavy usage, to a sad state of disrepair. The cost of a new wheel, even if such were available—and this was not thought to be likely—might easily have exceeded the actual capital value of the whole vehicle in its existing decrepit condition, so that s temporary repair was called for.

As an alternative, it was decided to try and make shift by changing front and rear wheels. A front wheel was found to be sound, but was mounted on a hub of smaller diameter than the rear wheel. The bore AVM, therefore, enlarged so as to accommodate the hub of the rear wheel, and that of the rear wheel was diminished to suit the smaller diameter of the front-wheel hub, by fitting a wooden ring which was driven into place ; it was so tight, at any rate, as to ensure that it *reinforced loose spokes of this rear wheel.

Further reinforcement of the decrepit rearrwheel, now converted for use as a front wheel, was afforded by driving staves in between each pair of spokes, staves which fitted tightly between the 'kilt* and the junction of the spokes. It hats to he admitted that this procedure did not enhance the appearance of the vehicle itself, but at the same time, as a repair, it has proved to be quite a success.

'"-J.E.," of Leyton, had the misfortune to split the steel base of a solid tyre of his vehicle—a '3-termer. The effect was to loosen the tyre on the wheel, allowing it to slip off so easily and frequently that. he had to stop about every 200 yards to drive it back again into place, from which it was continually slipping. Eventually he discovered a smith's shop, and there had made some clips, as shown in the sketch. Four of

these were driven between tyre and wheel while still hot, being subsequently bent upwards so that one end of the clip was in contact with the wheel rim on its inner tide, the other with the base of the tyre on its outside. With the aid of these clips he was able successfully to travel home.

"M.M.," of London, W., tells us that he bad on one occasion unexpected and unusual trouble with the rear wheels of a chain-driven 2-ton Thernycroft. They ran hot at. the outside of the bearing. Various expedients were tried in order to prevent this, but without success. Eventually, on careful examination of the axle, it was remarked that, if care was not taken, it was possible to replace the axle in the chassis the wrong way round, and, as a matter of fact, it was discovered that this was precisely what had happened, so that the ends of the axle inclined upwards (as indicated by the dotted lines on the sketch), instead of in a downward direction, as is correct. The effect of this mistake was to cause the wheels always to be trying to come off the axle, thus making them bear hardly against the thrust washers.