A QUESTION OF QUALITY

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

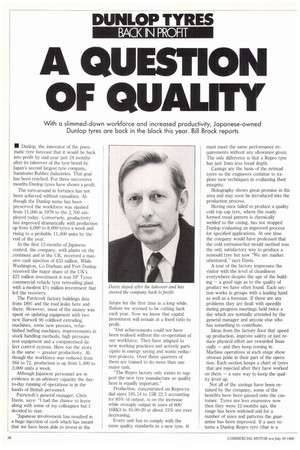

With a slimmed-down workforce and increased productivity, Japanese-owned Dunlop tyres are back in the black this year. Bill Brock reports

• Dunlop, the innovator of the pneumatic tyre forecast that it would be back into profit by mid-year just 24 months after its takeover of the tyre brand by Japan's second largest tyre company, Sumitomo Rubber Industries. That goal has been reached. For three successive months Dunlop tyres have shown a profit.

The turn-around in fortunes has not been achieved without casualties. Although the Dunlop name has been preserved the workforce was slashed from 11,000 in 1979 to the 2,700 employed today. Conversely, productivity has improved dramatically with production up from 4,000 to 8,000 tyres a week and rising to a probable 11,000 units by the end of the year.

In the first 12-months of Japanese control, the company, with plants on the .continent and in the UK, received a massive cash injection of £53 million. While Washington, Co Durham and Fort Dunlop received the major share of the UK's 221 million investment it was SP Tyres commercial vehicle tyre retreading plant with a modest 21/2 million investment that led the recovery.

The Patricroft factory buildings date from 1891 and the roof leaks here and there. However, most of the money was spent on updating equipment with two new Barwell 90 coldfeed extruding machines, some new presses, refurbished buffing machines, improvements in stock handling methods, high pressure test equipment and a computerised defect control system. Here too the story is the same — greater productivity. Although the workforce was reduced from 164 to 72, production is up from 1,400 to 2,000 units a week.

Although Japanese personnel are in evidence in an advisory capacity the dayto-day running of operations is in the hands of British personnel.

Patricroft's general manager, Chris Davis, says: "I had the chance to leave along with some of my colleagues but I decided to stay.

"Japanese involvement has resulted in a huge injection of cash which has meant that we have been able to invest in the future for the first time in a long while. Before we seemed to be cutting back each year. Now we know that capital investment will remain at a fixed ratio to profit.

"Our achievements could not have been realised without the co-operation of our workforce. They have adapted to new working practices and actively participate in energy saving and waste reduction projects. Over three quarters of them are trained to do more than one major task.

"The Repro factory only exists to support the new tyre manufacture so quality here is equally important."

Production, concentrated on Repro/radial sizes 185.14 to 15R 22.5 accounting for 85% of output, is on the increase while crossply output in sizes of 600 16Rk3 to 10.00-20 at about 15% are ever decreasing.

Every unit has to comply with the same quality standards as a new tyre. It must meet the same performance requirements without any allowance given. The only difference is that a Repro tyre has just lmm less tread depth.

Casings are the basis of the retread tyres so the engineers continue to explore new techniques in evaluating their integrity.

Holography shows great promise in thi! area and may soon be introduced into the production process.

Having once failed to produce a quality cold top cap tyre, where the ready formed tread pattern is chemically welded to the casing, has not stopped Dunlop evaluating an improved process for specified applications. At one time the company would have professed that the cold extrusion/hot mould method was the only satisfactory way to produce a remould tyre but now "We are market orientated," says Davis.

A tour of the factory impresses the visitor with the level of cleanliness everywhere despite the age of the building — a good sign as to the quality of product we have often found. Each section works in groups with a leading hand as well as a foreman. If there are any problems they are dealt with speedily during progress meetings held twice a day which are normally attended by the general manager and anyone else who has something to contribute.

Ideas from the factory floor that speed up production, improve safety or just reduce physical effort are rewarded financially — and they keep coming in. Machine operatives at each stage show obvious pride in their part of the operation. Each section keeps a chart of tyres that are rejected after they have worked on them — a sure way to keep the quality level up.

Not all of the savings have been retained by the company, some of the benefits have been passed onto the customer. Tyres are less expensive now then they were 12-months ago, the range has been widened and for a number of sizes and patterns the guarantee has been improved. If a user returns a Dunlop Repro tyre (that is a