HINTS ON MAINTENANCE.

Page 30

Page 31

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Troubles.

CONTRIBUTIONS are invited for this page from fleet managers, drivers, garage foremen and mechanics, works staff and draughtsmen, and will be paid for on .ki, generous scale. Every system, make, and type of commercial motor vehicle will be dealt with, and the matter should be written with a view to the disclosure of workshop and garage practice in the maintenance of a vehicle—practices 51.—The J Type Thornycroft Engine.

To maintain the efficiency of the Thornycroft engine, the valve clearances should be adjusted to not less t)mat .006 in. for the inlet and .008 in. for the exhaust. Make certain -also that the valves do not stick in their guides, especially in the case of the exhaust. They ate easily removed, and it is advisable to take them out once a week for cleaning.

It is as well for those who have bought secondhand vehicles to check the valve timing. The inlet valves should open 2 ins, before top dead centre, and closca4 ins. to 6 ins, after top dead centre. The exhaust valves should open 8 ins. before bottom dead centre and close 2 ins, after the top dead centre, these measurements being taken on the periphery or the flywheel. It should be noted that the. two studs for adjusting the clutch springs are plae-eti so that, when they -come opposite the pointer, they indicate that one or other pair of the pistons is at the top dead centre.

52.—Napier Rear Spring Brackets.

On sonic of the earlier -type Napier lorries the front brackets of the rear springs show a tendency to crack close up to the frame. The brackets should

therefore he watched carefully for the first signs of any such fracture, and if taken in time they can be saved by a good welder ; failing that, a new part should be obtained from the makers and fitted immediately. Attention to this point may save a hold-up on the road.

53.—Some Notes on Steam Valves.

When fitting a new valve, it should always he positioned so that the steam from the boiler comes under the seat and not over it, otherwise the valve is working the wrong way about. Always use a spanner which fits the hexagon and do not use pipe wrenches B34

which, whilst they may be quite normal, are peculiar to the particular vehicle and may not be generally known to those responsible for its running. Expedients and suggestions for overcoming roadside and other troubles are covered in the following page, headed "Roadside and Garage." Communications should be addressed to " The Editor, The Commercial Motor, 7-15, Rosebery Avenue, London, E.C. 1."

or Footprints, as they invariably round off the corners and may render the task of removing the valve extremely difficult. If possible, do not remove the top from the bottom of a valve, or the plug from a cock. This is not alwa-ys possible, but, if separated, theaparia should be very carefully replaced after fitting ; also, if the seat is removable, see that it is replaced in the correct position. When screwing up into place, if the valve has two hexagons, use the spanner on the hexagon nearest to the part to which it is being screwed, as otherwise the body of the valve may be strained. Also, when holding a valve in the vice, always place it so that there is no danger of squeezing the threads.

54.--Care of the Remy Ignition.

A large number of Peerless lorries are fitted with the Remysystem of ignition, consisting of a low-tension magneto with coil and accumulator. Complaints about this ignition-are often made by drivers, and the trouble usually proves to be caused by lack of attention. As compared with the high-tension magneto, there are several extra external connections which must be clean and make good contact. There arethree between the magneto and coil which call for special attention. These are low-tension connections and subject only to voltages in the neighbourhood of 20 and 30. Any dirty or loose connections at either end of any of these three leads will considerably reduce the voltage induced in the secondary winding, and will almost certainly cause misfiring, for if the primary circuit cannot operate properly neither can the secondary. .A loose contact in a high-tension wire connection is less vital, there being ample voltage ta bridge any small gap.

The Remy system gives, equally good results as the high-tension magneto, when properly looked after.

Another point which' must be attended to is that the accumulator does not quite fill ita box, and more than one case has come to our knowledge in which the remaining space has been filled with odd Spanners, bits ofchains, etc. In one instance these -*ere placed on top or the accumulatdr, and yet the driver could not understand why his vehicle would not start up or run on the -battery. The battery -box has provision for a padlock, and should be accessible only to the person responsible for keeping the accumulator charged and in good condition.

55.—Wheel Alignment on Steam Wagons.

The matter of wheel alignment is of great import. ance, as the life of the tyres depends to a great extent upon the care taken in this respect.

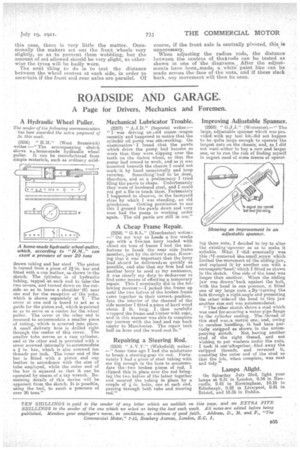

Periodically it is necessary to examine the front wheels of ia wagonto see that they are set properly. A front wheel can be tested by laying a long straightedge, such as a plank, against the face of the corresponding back wheel. Set one front wheel so that the distance between the straightedge and each side of the wheel is exactly the same. Do not move.the steering, but test the other front wheel in a, similar manner, and if the two distances are the same in

this case, there is very little the matter. Occasionally the makers set out the front wheels very slightly, so as to prevent them wobbling, but the amount of set allowed should be very slight, as otherwise the tyres will be badly worn. The next thing to do is to test the distance between the wheel centres at each side, in order to ascertain if the front and rear axles are parallel. Of course, if the front axle is centrally pivoted, this is unnecessary. When adjusting the radius rods, the distance between the centres of thetrods can be tested as shown in one of 'the diagrams., After the adjustments have been,made, a white paint line can be made across the face of the'nuts,• and if these slack back, any movement will then be seen. •