With Intent to Improve. 4

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

A Weekly Summary of Recent Patents' of Interest to the Maker and User of Commercial Motor Vehicles.

Selected and Abridged by H. S. Hall, A.M.I.A.E.

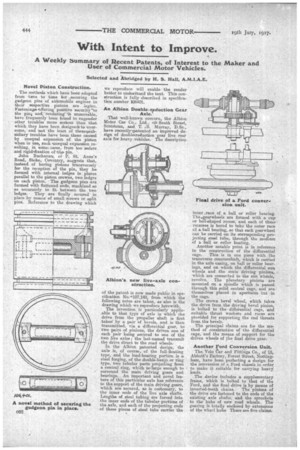

Novel Piston Construction.

The methods which have been adopted. from • fans to time or .securing the gudgeon pins of automobile engines in their Fespective pistons are legion. Fasteninsasssffering positive security'to the pin; and: rendermg"it immovable, have frequently been found to engender other troubles more serious than that which they have been designed‘ to overcome, and not the least of theseesubsidiary troubles have been those caused by unequal expansion of the piston when in use, such -unequal expansion resulting, in some cases, from too secure and rigidsfixation of.itla.fs

John Buchanan., i3f P. St. Anne's Road, Stoke Coventry, -suggests that, instead of boring pistons transversely for the reception of the pin, they be formed with internal ledges in planes parallel to the piston crowns, two ledges on each piston. The gudgeon pins are formed with flattened ends, machined 60 as accurately to fit between the two ledges.' They are finally secured in place by means of small screws or split pins. Reference to the drawing which we reproduce will enable the reader better to underStand the text. This construction is fully ,described in specification number 106401.

An Albion Double-reduction Gear Axle: That well-known concern, the Albion Motor Car Co., Ltd., ofe South Street, Scotstoun, and T. 1. Murray, D.Sc., have recentlyspatented an improved design of double-reduction gear live rear axle for heavy vehicles. The description of the patent is now made public in specification No.q107,149, from which the following notes are taken, as also is the drawing which we reproduce herewith. The invention is particularly applicable to that typo of axle in which the drive from the propeller shaft is first taken by a pair of bevels, and is then transmitted, via a differential gear, to two pairs of pinions, the driven one of each pair being secured to one of the two live axles; the last-named transmit the drive direct to the road wheels.

In the Albion patented design, the axle is, of course, of the full-floating type, and the load-bearing portion is a steel forging, of the double-banjo or ring type, two tubular parts projecting from a central ring, which iss large enough to surround the main driving gears and bearings._ An important and novel feature of -this particular axle has reference to the support of the main driving gears, which are secured, as is customary, to the inner ends of the live axle shafts. Lengths of steel tubing are forced into the inner ends of the tubular portions of the axle, and each of the projecting ends of these pieces of steel tube carries the

inner ,race of a ball or roller bearing. The gearwheels are formed with a cup or bell-shaped recess, and each of these recesses is bored to take the outer race of a ball bearing, so that each gearwheel can be carried on its corresponding projecting steel tube, through the medium of a ball or roller bearing.

Another notable point is in reference to the construction of the differential cage. This is in one piece with the transverse countershaft, which is carried in the axle casing, on ball or roller bearings, and on which the differential sun Wheels and the main driving pinions, which are connected to the sun wheels, revolve. The planetary pinions are mounted on a spindle which is passed through this solid central cage, and are ' themselves placed in apertures cut in the cage. The crown bevel wheel, which takes the drive from the driving bevel plain'', is bolted to the differential cage, and suitable thrust washers and races are provided for supporting the end thrusts frosn the bevels.

The principal claims are for the method of construction of the differential cage, and the means of support for the driven wheels of the final drive gear.

Another ford Conversion Unit.

The Vele &r and Fittings Co., of 15, Abbott's Factory, Forest Street, Nottingham, have been perfecting a design for the conversion of a Ford chassis in order, to make it suitable for carrying heavy loads. • The device includes a supplementary frame, which is bolted -to that of the Ford, and the final drive is by means of inverted-tooth chains. . The pinions of the drive are fastened to the ends of the eicistingaxle 'shafts, and the sprockets to the hubs ofnew road wheels. The gearing is totally enclosed by extensions of the wheel hubs. There are five elaims.