A PRIZE OF TEN SHILLINGS is awarded each week to

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

the sender of the best letter which we publiqi on this page; all others paid for at the rate of ei:pensy a line, with an allowance for photographs. All notes are edited before being publithed. Mention your employer's name, in confidence, as evidence of good faith. Address D., 11. and F., "The Commercial Motor," 7-15, Bosebery Avenue, London, E.C.

Lamps Alight.

Light your lamps at 9.31 in London, 10.36 in Edinburgh, 9.54 in Newcastle 9.51 in Liverpool 9.42 in Birmingham, 9.41 in Bristol, and 10.36 in Dublin.

Using Standard Piston Rings in Badly-worn Grooves.

The sender of the following communication has been awarded the 10s. prize this week.

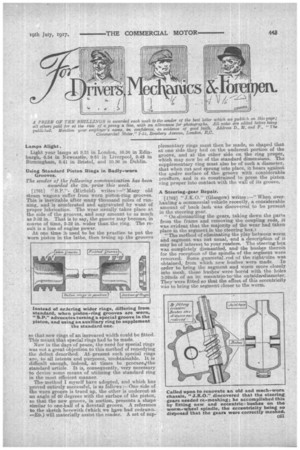

[1761] "8.1?."(Mirfield). writes :—" Many old steam wagons suffer from worn piston-ring grooves. This is inevitable after many thousand miles of running, and is accelerated and aggravated by want of proper lubrication. The wear usually takes place at the side of the grooveS, and may amount to as much. as 3-32 in. That is to say, the groove may become, in course of time, 3-32 in. wider than the ring. The result is a loss of engine power.

At one time it used to be the practice to put the worn piston in the lathe, then truing up the grooves so that new rings of an increased width could be fitted. This meant that special rings had to be made..

Now in the days of peace, the need for special rings was not a great objection to this method of remedying the defect described. At present such special rings are, to all intents and purposes, unobtainable. It is difficult enough, indeed, at times to procuretAhe standard article. It is, consequently, very necessary to devise some means of utilizing the standard ring hi the most efficient manner.

The method I myself have adopted, and which has proved entirely successful, is as follows :—One side of the worn groove is trued up, the other is undercut at an angle of 60 degrees with the surface of the piston, so that the new groove, in section, presents a shape similar to one-half of a dovetail groove. A reference to the sketch herewith (which we have had redrawn. ..En.) will materially assist the reader. A set of sup plementary rings must then be made, so shaped that at one side they bed on the undercut portion of the groove, and at the other side on the ring proper, which may now be of the standard dimensions. The supplementary ring must also be of such a diameter, that when cut and sprung into place, it bears against the under surface of the, groove with considerable pree§ure, and is so constrained to press the piston ring proper into contact with the wall of its groove.

A Steering-gear Repair.

[1762] "331.0." (Glasgow) writes :—" When overhauling a commercial vehicle recently, a considerable amount of' back lash was discovered to be present in the steering gear. " On.dismantling the gears, taking down the parts from the frame and removing the coupling rods, it was evident that the majority of the wear had taken place in the segment in the steering box.i

, "The method of eliminating the play between worm and segment was not usual, -and a description of it may be of interest to your readers. The steering box was completely dismantled, and the bushes therein for the reception of the spindle of the segment were removed. Some gunmetaLrod of the right.size was obtained, from which new bushes were made. In order to bring the segment and worm more closely into mesh, these bushes' were bored with the holes 3-32nds of an in: eccentric, to-the outsideediameter. They were fitted so that the effect of this eccentricity was to bring the segment closer to the worm.