'Aspe'cts of the Synthetic Rubber Position

Page 29

Page 30

If you've noticed an error in this article please click here to report it so we can fix it.

Many of Our Readirs. Should be Interested in the Points Raised by Dr. Pickles in His Paper Read Last Tuesday Before th: Royal Society of Arts

MANY of our readers are vitally interested in the supply of rubber, mainly in its most-used form, as tyres and inner tubes. Particular value, therefore, attaches to the paper "Rubber: Natural v.. Synthetic," read by ,Dr. S. S. Pickles, D.Sc., F.I.C., on February 16, before the RoyalSociety of Arts, With Sir George Beharrell, D.S.O., chairman, Dunlop Rubber Co., Ltd:, presiding.

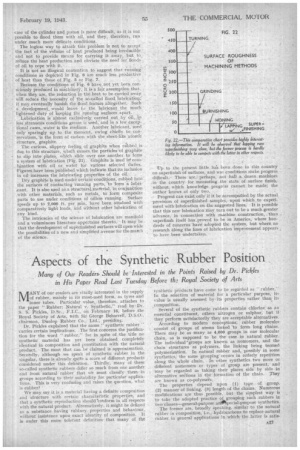

Dr. Pickles explained that the name "synthetic rubber" carries certain implications. The first concerns the justification for the word "rubber," for in spite of the title no synthetic material has yet been obtained completely identical in composition and constitution with the natural product. The most that can be claimed is approximation. Secondly, although we speak of synthetic rubber in the singular, there is already quite a score of different products considered under this definition. Thirdly, many of these so-called synthetic rubbers differ so much from one another and from natural rubber that wh must classify them in groups according to their suitability for particular applications. This is very confusing and raises the question, what is -rubber? • We may say it is,a material having a definite composition and structure with certain characteristic properties, and that a synthetic reproduction should'co'nform in. all respects with the natural product. Alternatively, it might be defined as a substance having robbery, properties and behaviour, without insistence upon exact identity of composition. It is under this more tolerant definitionthat many of the

synthetic products have come to he regarded as " rubber." In the selection of material for a particular purpose, its value is usually assessed by its properties rather than its composition.

Several of the synthetic rubbers contain chlorine as an essential constituent, others nitrogen or sulphur, but if they perform satisfactorily they are acceptable alternatives.

According to modern conceptions, rubber molecules consist of groups of atems linked 'to form long chains. There may be as many as 4,000 groups in one molecular chain, as is supposed to be the case in natural rubber. The individual 'groups are known as nomomers, and the chain structures as polymers, the linking being termed polymerization. In natural rubber and, possibly in some synthetics, the same grouping occurs in orderly repetition along the whole chain. In other synthetics two more or diflerent nomomers or types of group are present, and may be regarded as taking their places side by side in alternative sections in theformation of the chain. They are known as co-polymers. The properties depend upon ()) type of group,

up, (2) manner of linking, (3) length of the chains. Numerous modifications are thus possible, but the simplest way is to take the adopted practice of grouping such rubbers iv two classes—general-purpose andkecial-purpose synthetics. The former are, broadly speaking. similar to the natural rubber in composition, i.e., hydrocarbons to replace natural rhbber, in general applications in which the -latter is satis factory. Their -aim is to simulate rubber without aspiring to superiority in any particular direction. To this group belong the numbered Buna rubbers, the American and German Buna "S " type, the .Russian " S.K.B.," Hycar" T.T. " and the Butyl. It is on these that America is planning the largest production.

Special-purpose synthetic rubbers, whilst retaining typical rubber characteristics, possess definite superiority in certain properties, such as resistance to petrol and oil, heat, oxidation, and other agencies to, which natural rubber is susceptible. They differ from the natural material in containing other elements, such as chlorine, nitrogen or sulphur as essential constituents, to which their special properties are in large measure due. Included in this group are the Ncoprenes; the Perbunans and the Thiokols.

' What Makers and Users Require The user is mainly interested in the properties of the vulcanized product," e.g., tensile strength, elasticity, resilience, resistance to abrasion, oil and heat, durability, permeability to gases, electrical properties and inflammability.

The maker is particularly concerned with the processing properties, with plasticising for manipulation, and obtaining the " tack " or adhesiveness necessary for building articles from sheets or plies. Vulcanization requirements have also to be considered.

Density is important, for this has a bearing on the volume cost of an article. The lighters-the material the more articles can be made from a 'given weight. Here the advantages lie with natural rubber and general-purposesynthetics, the sp. gr. of which lie between 0.91 and 0.93, whilst the sp. gr. of Perbunan, Hycar OR, etc., is 0.97; Neoprene, 1.25; Thiokols, 1.34 to 1.60.

High tensile strength is very desirable in many applications. In manufactured goods it is dependent to a large extent on the nature of the reinforcing materials employed, the highest results being obtained with carbon-black mixings, and in comparing different rubbers this type of -compound is generally used.

The following values of such compounds have been quoted by aeveral -authors, the figures representing load at break in kilos. per 'sq. cm., and elongation per cent.: natural, 350-650; Buna 85, 175-600; Buna 115, 200-700; Buna " 5," 280-650; Neoprene, 290-760; Perburian, 320-600; Thiokol " RD," '220-530.

Qualities of Synthetic Rubber Is a recent review bythe U.S. National Bureau of Standards, it is stated that no synthetic rubber compounds have been made with tensile strengths exceeding those of the best carbon-black compounds of natural rubber, but some approach fairly closely;

Natural rubber is also definitely superior to nearly all synthetics in resilience—the ability to return quickly to the original form after stretching or compression, with a minimum retention of energy. Poor resilience may lead to internal heating with undesirable effects. The published results concerning resistance to abrasion are somewhat conflicting. This quality is of extreme importance in the treads of tyres, and most of these statements refer to tread compounds: One authority states that tyres from Russian Butadiene rubber -have far snperior abrasion resistance to those-made from the natural product. It is being claimed that tyres from Buna S have.a 25 to 35 per cent. advantage in -this connection over the natural product, whilst the nitrogen-containing Perbunan is said to be superior to any other rubber, natural or -synthetic, inthis respect.

The susceptibility to oxidation and the swelling and softening effects constitute defects inherent in the natural product. As regards resistance to ageing and oxidation, both at normal and more elevated temperatures, most synthetic rubbers are equal or superior to the natural, but in nearly all cases synthetic varieties tend to harden on prolonged heating at high temperatures, whereas the natural cotnpounds sometimes become soft and tacky. Some of the former can be used in contact with hot oil attemperatures of 150 degrees C.,4ke with Neoprene, but Thiokols cannot be used under such conditions, as they tend to become plastic at above 100 degrees C.

The. hydrocarbons, as a class, are amongst the best non

conductors of electricity, and some synthetics are superior to rubber in dielectric properties.

The presence of such elements as chlorine and nitrogen are detrimental to the insulating properties, but they have compensating features, such as excellent resistance to the effects of active ozone from electrical discharges, sunlight and oily liquids.

Low permeability to water, necessary for certain clothing, hose, hot-water bottles, etc., together with flexibility, renderink it suitable for barrage balloons, gas masks, etc., are properties of rubber, but the synthetics are, in most cases, quite as satisfactory, the oil-resisting types being

generally -superior.

As to inflammability, the synthetics, particularly those containing chlorine, show a greater resistance to burning.

As regards processing, there are two main difficulties: First is the difficulty of plasticising to get rubber into a suitable condition for 'compounding and manipulating. Many synthetics are more difficult to break down than is natural rubber; this involves higher power consumption, loss of output, or the installation of more machinery, resulting in increased costs. The second is that of obtaining the adhesiveness -so necessary when building from plies. Some synthetics are " drier " than the natural rubber after mixing. If good adhesion be not obtained, there is a lack of consolidation which may involve premature breakdown. No doubt satisfactory solutions, of these problems will be . found.

Problem Is Natural Plus Synthetic

-These are not normal times, and freedom of choice is limited. Price is a secondary consideration, and makers are glad to use all the synthetic rubber that they are able to obtain. The problem is really one of natural ruliber phA synthetic rather than natural rubber versua synthetic.

America may ,produce something like 300,000 tons of synthetic in 1943, and 600,000 tong in 1944, but concern is being mipressed in mauy; quagers that there has been such little progress in the, production of this material in Britain. The chief obstacle, however, has been the fact that we have not here readily available supplies of the necessary basic raw materials.

The three main sources from which most of the world's synthetic is made are alcohol, petroleum and acetylene. Ta obtain, the first in sufficiently large iluantities would require a tremendouS amount of sugar, grain or potatoes— all valuable foodstuffs. Imported petroleum would .require expensive plant for cracking and separating. The materials for acetylene, Viz., coal and lime, we have in large quantities. but for the making of carbide very high temperatures are necessary, involving large-scale generation of electricity„ This calls for cheap power, preferably from water.

Produce Synthetic Rubber Here

However, it may he desirable that the situation regarding the manufacture of synthetic rubber here should be thoroughly investigated, and, if found practicable, arrangements made to augment our rubber supplies from this sOurce. Presumably this could be done only with (;overnment support, which would leave in its hands the power to curtail production later for: reasons of broad Empire policy. It may be noted here that the U.S.A. Government's contract with the Rubber Reserve Company provides that after the war the Government Will have the right to acquire . the plants.

Malay and the East Indies formerly produced about 90 per cent, of theworld's supply and represented an inveited capital of over £250,000,000. It would he a tragedy, -therefore, if a cut-throat competition Were allowed to develop to the permanent detriment of this industry. Over 1,000,000 non-Europeans are directly employed, and serious curtailment would mean that 'large numbers of natives would be reduced to something perilously near starvation.