Equipment that Expedites

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

the Efficient Handling of

GIANT PNEUMATIC TYRES

As a Perusal of this Article a and Will in the Long Run L Fact that, by the Use of Old-) Replacing Large, Low-pre5 how, Suitable Equipment Means Efficiency tbtedly Pay for Itself. It Emphasizes the )fled Methods of Removing, Repairing and Tyres, Time and Money May be Lost

WE witnessed an unusual occurrence the other day, when, in a busy street in London, we saw. the wheel of a pneumatic-tyred bus being changed. The rarity of this-occurrence may he measured by the comment and surprise it evoked. "Never seen 'em --do that before," is typical of the former.

"Not the least interesting feature of the proceeding was the type of wheelnut spanner used, this being about -31t. long. A tubular, extension was applied to it, bringing the total length up to about 8 ft., so that the device could be manipulated—we shall not say with ease—by a couple of really well-built members of the bus company's repair staff engaged on the job.

The incident, as we have said, was strangd to the point of being unique. The • organization in a modern bus garage is such that tyre trouble on the road is indeed rare. Part of that organization turns on the use of labour-saving equipment, designed not only to reduce the number of man-hours necessary . when handling giant pneumatic tyres, but also to make the work less of a Strain for those whose duty it is to remove, repair and replace such tyres. The accompanying illustrations exemplify modern tyre-handling equipment and show how it can be used.

The first step is, of course, the removal of the wheel from the vehicle, and for that purpose there does not appear as yet to be anything which can satisfactorily replace the "outsize" wheel-brace, to which we have already referred—at any rate, so far as the removal of the nuts which hold the wheel in place is concerned.

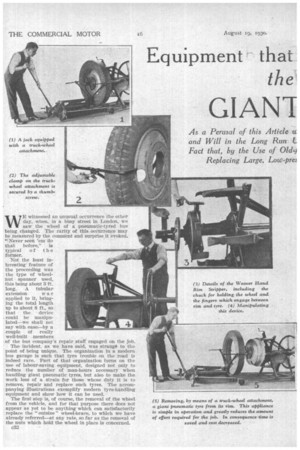

c32 The conveyance of the wheel from the vehicle can be facilitated if what is called a "truck-wheel attachment " be used in conjunction with a heavy jack. This type of device is depicted in one of these illustrations, in which a giant-tyred disc wheel, carried by such an attachment, is shown being placed in position upon a large-tyre remover.

The appliance is simple, consisting of merely a couple of upwardly and outwardly projecting arms mounted on a bracket, which is designed to engage with the• saddle of the jack and having two lower 'horizontal prongs. The last-named can be brought into position below, the tyre by manipulating the jack in the ordinary way. Two adjustable clamps, mounted on the upper arms, are then brought into position, so as to embrace the tyre and prevent the wheel from toppling over. The wheel can then be moved anywhere merely by propelling the jack on its trolley wheels.

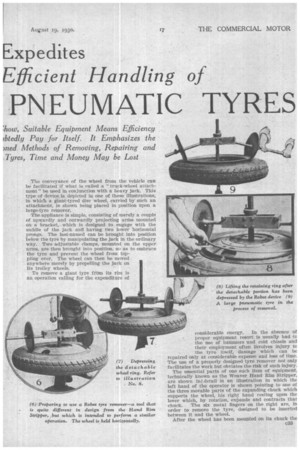

To remove a giant tyre from its rim is an operation calling for the expenditure of considerable energy. In the absence of proper equipment resort is usually had to the use of hammers and cold chisels and their employment often involves injury to the tyre itself, damage which can be repaired only at considerable expense and Joss of time. The use of a properly designed tyre remover not only facilitates the work but obviates the risk of such injury, The essential parts of one such item of equipment, technically known as the Weaver Hand Rim Stripper, are shown LW. detail in an illustration in which the left hand of the operator is shown pointing to one of the three movable parts of the expanding chuck which supports the wheel, his right hand resting upon the lever which, by rotation, expands and contracts that chuck. The six metal fingers on the right are, in order to remove the tyre, designed to be inserted between it and the wheel.

After the wheel has been mounted on its chuck the c33

ix fingers, which are hinged near their ends, are rought down to the correct diameter by manipulation E a hand lever, so that the tips of the metal fingers aaeh the junction between tyre and wheel. The large and wheel is then rotated in order to propel the fingers 3rwards and thus remove the tyre. This wheel nd screw exert a pressure in excess of 20,000 lb. Other illustrations show the wheel actually being mured in place on the machine and the tyre being emoved and taken away by means of the self-same ack and truck-wheel attachment, which served for its emoval to the Hand Rim Stripper.

Another giant-tyre remover, different but equally erviceable, is the Robot.

In this the wheel is lifted on to a horizontal table, ist of all with the retaining ring upwards. From he centre of the table a vertical screw projects. A entral bracket, with -a hub bored to fit this spindle nd having outwardly projecting spindles carrying ota table discs, is then placed in position, and the discs re adjusted so that they rest upon the retaining ring. A loose nut is next run down the spindle until a

spring-held cotter engages a corresponding hole in the hub of the bracket. The operator then takes hold of the end of one of the horizontal spindles and walks around, carrying it with him. As he does so the nut forces the brackets and discs downwards, taking the retaining ring with it, thus freeing the ring which holds that retaining ring, so that it can easily be removed. The nut, the bracket and the retaining ring are then removed.

The wheel is afterwards turned over on its table, the horizontal bracket replaced, but with the projecting spindles set in a new position, so that the discs on those spindles bear at an angle upon the edge of the tyre. The -nut is then once more replaced ; the operator again turns the bracket until the downward pressure causes the tyre to slide downwards off the rim of the wheel.

The Weaver equipment is obtainable from numerous agents, of which Blown Bros., Ltd., 22, Great Eastern Street, London, E.C.2, is one. The Robot device is marketed by Harvey Frost and Co., Ltd., 148, Great Portland Street, London, W.1.