NARRATIVES OF THE INDUSTRY.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

The Evolution of the Prominent Concerns in the British Commercial Vehicle Industry which have Made History by the Pursuit of a Progressive Policy.

LEYLAND MOTORS LTD.

ALL THOSE engaged in any branch of the commercial vehicle industry will, we think, unhesitatingly admit that the reputation which Leyland Motors Ltd. at present enjoy can only have been achieved by dint of a perfect understanding of the many-sided problems associated with road transport development. The knowledge of these problems has not been acquired through superficial channels but is built up on the solid foundation of experience—experience dating back to the earliest days of the industry when the use of mechanical vehicles was eschewed by all but the most enterprising of business homes.

As a matter of fact, to trace the growth and development of Leyland Motors Ltd. it is necessary to go back to the days of the wayside blacksmith's shop, for there is a distinct link between the present company and the picturesque old forge which, at one time' was an inseparable feature of the quaint little village of Leyland. It was at that forge that Elias Sumner carried on the business of blacksmith established by his ancestors.

He was assisted in the work by his son, Richard, who, being of rather an inventive turn of mind, contrived in his spare time to build the first steam engine produced in Leyland, and this machine was actually in use in the village for a considerable number of years. On the death of his father, Richard Sumner took steps to develop the business, and erected a small foundry and engineering shop. At this time he was engaged in the manufacture of railway wagons, but as certain difficulties were experienced in transporting the completed products this work was abandoned.

In 1889, his son, James, apparently imbued with his father's natural aptitude for the mechanical, turned his attention to the design of a steam wagon which was actually constructed and was the forerunner of the type of steam wagon now produced by Leyland Motors Ltd., although, of course, its features of design were somewhat crude and its parts unnecessarily heavy owing to the use of unsuitable steels.

From this period the company's evolution and association with mechanical transport productions can be clearly traced. It was a year or two later that an experimental steam tricycle was built as well as a steam lawn-mower. In each of these machines the experience gained in the design of the steam 1330 wagon was turned to good account, and the lawn-mower proved to be distinctly successful in use.

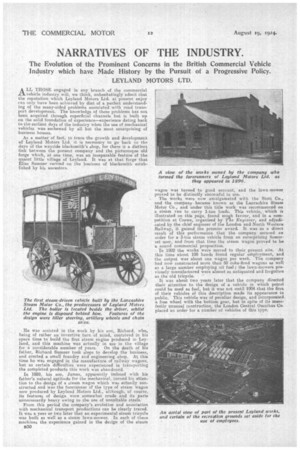

The Works were now amalgamated with the Stott Co., and the company became known as the Lancashire Steam Motor Co., and under this title work was recommenced on a steam van to carry 1-ton loads. This vehicle, which is illustrated on this page, found muih favour, and in a competition at Crewe, organized by nis Engineer, and adjudicated by the chief engineer of the London and North Western Railway, it gained the premier award. It was as a direct result of this performance that the company secured au order for a 3-ton steam vehicle from an enterprising Somerset user, and from that time the steam wagon proved to be a sound commercial proposition. In 1902 the works were moved to their present site_ At this time about 100 hands found regular employment, and the output was about one wagon per week. The company had now constructed more than 50 coke-fired wagons as well as a large number employing oil fuel; the lawn-mowers previously manufactured were almost as antiquated and forgotten

as the old tricycle. —

It was about two yearslater that the company directed their attention to the design of a vehicle in which petrol could he used as fuel, but it was not until 1904 that the first of their vehicles of this description made its appearance in public. This vehicle was of peculiar design, and incorporated a free wheel with the bottom gear, but in spite of its manifestly unusual construction, the London Central Omnibus Co. placed an order for a number of vehicles of this type.

At a somewhat earlier date, a 30-cwt. petrol-driven chassis, in which a twin-cylinder engine of the T-headed pattern was used had been designed.

This unit had a bore of 4L ins, and a stroke of 6 ins., and developed 12 .b.h.p. at 800 r.p.m. That this was an age when speed was apparently not an essential feature of business life is suggested by the fact that although this was approximately the maximum speed of the engine it was deemed expedient to fit a governor. The engine had two camshafts; the ignition was by means of a coil and accumulator, whilst a honeycomb-type of radiator was responsible for the cooling arrangement.

The engine drive was taken through a cone clutch to a three-speed-and-reverse straight-through type gearbox, and a cardan shaft with gunmetal dies led to the spherical thrust— an embryonic version of the present standard Leyland pattern. It had, however, this difference, that the universal joint was situated in front of the spherical thrust member instead of within it, as in modern practice. The propeller shaft conveyed the power to a single bevel live axle, the wheels being keyed direct to the driving shafts. The wheels were of the composite type, with a cast malleable centre and wooden felloes, and the tread was a steel band. The front springs were 3 ft, long and those at the rear 6 ins. longer, and except for the forward ends of the front springs, which were pivoted, the ends were attached to sliding slippers, This vehicle had a joggled frame, 2 ft. 6 ins. wide in front and 3 ft. 6i ins, wide at the rear.

At the' time that the first vehicles were supplied to the London Central Omnibus Co., the output of the Leyland factory was at the rate of two steam wagons and an occasional petrol wagon per week, but from now onwards the internalcombustion-engined vehicle began to oust. its parent from popularity.

The use of special steels was then a science undeveloped, and it is little wonder that replacement parts were continually being sought when it is realized that gearwheels were made of malleable cast-iron. It is a fact that many a chassis which stood almost complete in the afternoon was the following morning half dismantled, the storekeeper's stock having been insufficient to meet a rush demand.

In spite of these trials and tribulations the company continued to grow and expand, and their premises were enlarged to meet the constantly increasing demand for their products. By the year 1912 the production of steam wagons was relegated to the background, whilst the manufacture of petrol wagons was proceeding at the rate of five or six per week. The early years of experimenting with petrol-driven models were at length rewarded with a Government subsidy for the

company's 4-ton vehicle. Although the design of this machine is 11 years old, many of the features it embodied are to be found in a somewhat modified form in present-day models.

About. this period experiments were being undertaken with fire-fighting plant, and ultimately a highly satisfactory model was placed on the market. This became such a feature of the company's activities that in 1913 a factory devoted specifically to this branch of production was taken over at Chorley in Lancashire, and the manufacture of steam wagons was also relegated to these works.

A few months before the outbreak of war the title of the company was changed to Leyland Motors (1914), Ltd. A n;ght sift was then in regular operation, and 10 vehicles were being produced every week. Upon the declaration of hostilities the complete output of the works was, of course, commandeered by the Government, which even had four fire-engines nearing completion stripped so that their wilts could be utilized for other purposes.

The works were eventually enlarged .to three times their existing size, and production figures naturally leapt in response, and 40 vehicles per 'week was the maximum output of completed machines, although the construction of spare parts was equivalent lo about a further 20. The power house and foundry at Farington (which are electrically equipped) came into being in 1916-1917.

After the close of the war the company took over a large works near Kingston, in Surrey, for the purpose of rebuild-' log a considerable number of ex-R.A.F. lorries which had been bought back from the Government, and over 2,000 of these machines have now passed into the bands of civilian users after having been subjected to the most comprehensive overhaul and examination.

The company's vehicles have during the growth of the industry participated in many competitive events from which

they have emerged With flying colours. The first award which was ever obtained was in 1897, when a silver medal

(the highest award for self-moving vehicles) was awarded by the Royal Agricultural Societe of England. In the following year one of their vehicles received a £100 award from the same source. In the notable Liverpool Trials of 1901, a Leyland vehicle received a gold medal—the highest award. In March, 1903, and September, 1904, examples of their vehicles received silver medals from the Lancashire Agricultural Society. As a result of successful participation in War Office Trials for subsidy vehicles in 1912, the Leyland became the first War Office subsidized machine.

Although it is not possible to indicate the exact size of the company's works at Leyland, the area covered by the steel works and power house is approximately two acres, whilst the floor area of the Kingston shops is 340,500 sq. ft. Some idea of their activities, however, can be gauged from the fact that all types of goods vehicles are available for loads of from 30 cwt. to 6 tons, whilst others are expressly designed for passenger service, these including a range of bus and char-a-banes models. There are three models of fire-engines and, in addition, a highly efficient power-driven portable pum i p s manufactured, and, lastly, reference should be made to the Trojan van which, with its solid-tyred wheels and excellent system of suspension, is proving most popular in certain branches of commercial motor transport.