• ROADSIDE AND GARAGE.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

A Page for Drivers, Mechanics and Foremen.

A Ventilated Soldering Flux and Acid Cabinet.

The sender of the following commiovication has been awarded the .extra payment of 5s. this week.

(2215) " Foreman " (Manchester) writes:—" Since we began repairing our own radiators and doing a lot of sheet nietal work, we have naturally been using a good deal of acid for soldering flux and also for cleaning metal parts. Every mechanic who has ever worked in a shop where much soldering is done knows that the stopper is very frequently left out of the add bottle. The fumes which come off the acid rust all the iron and steel parts within range, and for a lung time we had just this sort of trouble in our own place, until I had the idea of making a cabinet in which the acids could be kept.

" First of all, .I got, four widemouthed bottles each holding about half .a gallon. They were fitted with ground glass stoppers, and were, therefore, per fectly gas tight. Thebottles, themselves, were 54 ins, diameter, which gave an indication of the necessary measurements of the cabinet, which I made 12 ins, square and 14 ins. high. The door in the front was made to close tightly, and fitted with a turn-buckle fastener.

" Care was taken When making the cabinet and the door so that as little surface as possible was subject to any acid fumes that might escape, and two coats of asphalt varnish were applied to the interior of the cabinet to protect the sheet metal of which it was made. A perforated wooden tray with two strips on the inside to raise it from the floor of the cabinet was placed inside. To improve the efficiency of the cabinet, I made arrangements or it. to be automatically ventilated. I drilled

a bole in the shop wall just below the cabinet, and through that ran 'a length of 2i in. galvanized iron pipe, the lower end of which was open to the atmosphere outside, the other • end opened into the cabinet itself. A second pipe similarly communicated, as shown in the sketch, between the top of the cabinet

and outside. These arrangements ensured a constant current of fresh air running through the cabinet, carrying

off any acid fumes that came off, •

An Anti-dazzle Tip.

(2216) " J.D." (Wolverhampton)

writes :—"Most of us are bothered from time to time with the glare from the headlights of advancing cars, lorries, or other road vehicles. Sometimes, after meeting a vehicle on the road, it is almost impossible to see where one is going. I find the following little tip very •iiseful. I take a piece of tinted celluloid, amber or green, 3 ins. wide and 6 ins, long, and fasten it on to the windscreen a little to the right of the view ahead when sitting naturally at the wheel. When a vehicle approaches, the lights of which are too strong for my eyes, I just lean to the right and look through the celluloid until it has passed by. This entirely relieves the strain."

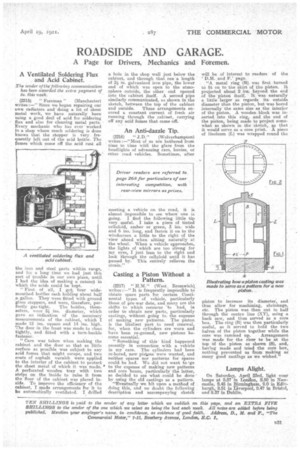

Casting. a Piston Without a Pattern.

(2217) " KM." (West Bromwich) writes :—" It is frequently impossible to obtain spare parts for certain Continental types of vehicle, particularly those of pre-war date, and many are the shifts to which recourse is had, is order to obtain new parts, particularly castings, without going to, the expense of making new patterns. The piston is the likeliest part to need renewal, fur, when the cylinders are worn and have been re-ground, new pistons became essential.

" Something of this kind happened recently in connection with a vehicle in my care. The cylinders had been re-bored, new pistons were wanted, and neither spares nor patterns for spares couldbe had. We did not, want to ;"go to the expense of making new patterns and core boxes, particularly the latter, so decided to see what could be done by using the old castings as a pattern.

"Eventually we hit upon a method of doing this, and no doubt the following description and apcompanying sketch will be of interest to readers of the 'P.M. and F.' page.

"A metal ring (R) was first turned to fit on to the skirt of the piston. It projected about 2 ins. beyond the end of the piston itself. It was naturally a little larger as regards its outside diameter than the piston, but was bored internally the same size as the interior of the piston. A wooden block was inserted into this ring, and the end of the piston, being i made to project somewhat as shown n the sketch, so that it would serve as a, core print. A piece of linoleum (L) was wrapped round this

piston to increase its diameter, and thus allow for machining, shrinkage, etc. The piston was then cut in half through the centre line (XY), using a hack saw, and thus served as a Core box. The ring (R) was then particularly useful, as it served to hold the two halves of the piston together while the

core was rammed up. Arrangement was made for the riser to be at the top hi the piston as shown (S), and, having made and tried the core how, nothing prevented us from making as many good castings as we wished."

Lamps Alight.

On Saturday, April 23rd, light your lamps at 8:37 in Lors3on, 8.50 in Newcastle, 8.45 in Birmingham, 9.0 in Edinburgh, 8.51 in Liverpool, 8.47 in Bristol, and 9.37 in Dublin.