A NEW 3-TONNER OF CLEAN DESIGN.

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

The Latest Vulcan Goods Chassis with a Twopiece Propeller Shaft, Transmission Brake, Worm Drive and Underslung Rear Springs.

MHE already large range of commercial chassis manufac

tured by the Vulcan Motor and Engineering Co. (1906), Ltd., Crossens' Southport, has just been augmented by a new 3-ton model, which is remarkable for its clean and robust construction. It is the type of chassis which should appeal to the user, as it is comparatively simple and should, therefore, prove easy to maintain, whilst it embodies the most up-to-date practice and is excellently sprung.

An engine considerably more powerful than that employed on the 21-ton model is utilized. It is a four-eylindered monobloc of 110 mm. bore and 140 mm. stroke giving a capacity of 5,320 c.c. (This compares with the 100 mm. stroke and 130 mm. bore of the unit on the 21-tonner.) At 1,000 r.p.m. it develops 39 b.h.p., and at 2,000 r.p.m. 60 b.h.p., so that the power curve has a speedy rise which is carried well over the higher speeds. To facilitate decarbonization, the cylinder head is detachable in one piece and four lugs are provided for lifting purposes. Priming cocks are supplied and an aluminium water pipe of ample size is bolted to the head.

A good point in the design is that the main bearing bolts are extended through the crankcase and serve to secure the cylinder block. Three-point suspension is employed to isolate the unit from the effects of any frame distortion. To afford good carburation a hot-spot is obtained by combining the inlet and exhaust manifolds.

The water pump and fan, driven by a link belt, form a unit which is mounted at the front of the cylinder block. The single gland can easily be adjusted.

Carburation is effected by a Zenith horizontal instrument

of 42 mm. bore, and ignition is by Simms high-tension magneto bolted to a platform at the off side of the crankcase. It is connected by er Simms coupling to its driving spindle, which is mounted on ball bearings.

Three per cent. nickel steel is the material used for the valves, which have a throat diameter of 21 ins. They are operated by silent roller tappets working in oil mist received from the crankcase.

Three. large bearings support the camshaft, which is of C.N.Y. steel. •

Aluminium alloy is used for the pistons, which have 1-in. ease-hardened gudgeon pins so fitted that, if they work loose, scoring of the cylinder walls is impossible.

The crankshaft is a 40-ton steel stamping equipped with a double ball-thrust washer. The crankpins and the three main bearings are of 21 ins. diameter.

White-metal-lined bronze shells are employed in the bigends of the connecting rods, which have two-bolt caps and are of the same material as the crankshaft. The big-ends may be inspecteol by removing the lower half of the crankcase.

• -A Renold silent chaiu, 1.6-in, wide and 1-in. pitch, -is arranged to -form a triangular drive from the crankshaft pinion to the camshaft and magneto; adjustment is. effected externally, by moving a jockey Pulley running on largediameter ball bearings.

Removal of the timing cover can be effected without disturbing the chain drive.

There is a breather on the upper half of the crankcase and a combined filler and breather in an accessible position on the timing cover.

To facilitate timing the various settings are clearly marked on the rim of the flywheel, and these can be set to a fixed pointer on the cylinder block.

To circulate the lubricant there is a gear-type pump submerged in the sump and driven by skew gears from the camshaft It forces oil thiongh a pressure filter to the main bearings, the oil passing through steel pipes and holes drilled in the crankshaft and crankcase to the big-ends, camshaft bearings and tim

ing chain. There is an accessible suction filter in the 'sump, and this may be withdrawn for cleaning purposes without losing the main body of oil. Incidentally, this is one of the good points which have resulted from the W.D. subsidy requirements. A dipstick is mounted at the near side of the crankcase and a large-diameter drain plug fitted in the bottom of the sump.

The clutch is an external coro type faced With Ferodo. It has three easily adjustable springs and

a clutch stop. Plexible fabric joints connect the clutch to the gearbox, and it is pleasing to note that the clutch may be withdrawn without affecting either the engine or gearbox.

Made of aluminium and as a separate unit, the gearbox is suspended at four points from two chanuebsteel cross-members. It provides four speeds forward and a reverse, the ratios being as follow: Top, 7 to 1; third, 10.85 to 1; second, 1.7.9 to 1; first, 28 to 1, and reverse, 37.4 to 1. Large-diameter shafts running on ball bearings serve to carry the stub-tooth gears. Central gear control is provided, and there is a safety catch for the reverse on the' change-speed lever. There are a breather on the filler cap and an oil-level cock at the side of the case.

Behind the gearbox is a ribbed brake drum with internal, expanding shoes faced with fabric. The drum has a diameter of 12/ ins., and the shoes are operated by a pedal. At this point we may mention that the hand-lever controls expanding shoes, also fabric' faced, in wheel drums 19 ins, in diameter.

An intermediate, self-aligning bearing divides the two-piece tubular shaft, which has joints of the Spicer type completely enclosed and lubricated with soft grease.

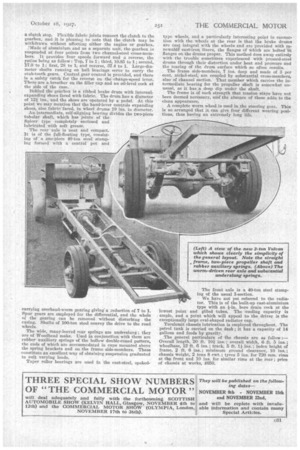

" The rear axle is neat and compact. It is of the full-floating type, consisting of a one-piece 40-ton steel stamping formed with a central' pot and carrying overhead-worm gearing givinia reduction of 7 to 1. Spur gears are employed for the differential, and . the whole of the gearing can be removed without disturbing the casing. Shafts of 100-ton steel convey the drive to the road S wheels.

The wide, many-leaved rear springs are underslung ; they are of Woodhead make, Used in conjunction with them are rubber auxiliary springs of the hollow double-coned pattern, the ends of which are accommodated in cups mounted above the spring brackets and on the frame side-members. These constitute an excellent way of obtaining suspension graduated te suit varying loads.

Taper roller bearings are used in the cast-steel, spoked type wheels, and a particularly interesting point in connection with the wheels at the rear is that the brake drums are cast integral with the wheels and are provided with renewabld cast4ron, liners, the flanges of which are bolted to flanges on the drums proper. This method does awaiy entirely with the trouble sometimes experienced with pressed-steel drums through their distortion under heat and pressure and the tearing of the drum surface which so often results.

The frame side-members, 7 ins. deep and made of 3 per cent, nickel-steel, are coupled by substantial cross-members, also of channel section. That member which carries the intermediate bearing for the propeller shaft is somewhat unusual, as it has a deep dip under the shaft.

The frame is of Such strength that tension stays have not been deemed necessary, and the absence of these adds to the clean appearance. .

A complete worm wheel is used in the steering gear. This is so arranged that it can give four different wearing positions, thus having an extremely long life.

The front axle is a 40-ton steel stamping of the usual I-section.

We have not yet referred to the radiator. This is of the built-up cast-aluminium type with an Fin. bore drain cock at the lowest point and gilled tubes. The cooling capacity is ample, and a point which will appeal to the driver is the exceptionally large oval-shaped radiator cap.

Tecalemit chassis lubrication is employed throughout. The petrol tank is carried on the dash ; it has a capacity of 14 gallons and feeds by gravity.

The general particulars of the chassis are as follow:— Overall length, 20 ft. 10/. ins..; overall width, 6 ft. 5 ins.: wheelbase, 12 ft. 6 ins.; track, 5 ft. 1/ ins.; laden height of frame, 2 ft. 6 ins.; minimum ground clearance, 10 ins.; chassis weight, 2 tons 8 cwt.; tyres 5 ins. for 720 mm. rims at the front and 10 ins, for similar rims at the rear ; price of chassis at works, £650.