MAKING BEST USE OF THE FORD.

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport which will appeal to the Owner, Driver, and Repairer.

408.—Inserting the Pistons into the Cylinders.

After fitting new rings on the Ford piston, one way of making certain that they have plenty of oil before being inserted into the cylinder is first to push the skirt of the piston and the bottom ring into position, then, with the cylinder block lying in such a manner that the piston projects practically horizontally, to pour oil into the hollow 4. gudgeon pin, one finger of the other hand stopping the bottom of the hole in tae pin, which thus forms practically an oil reservoir. The remainder of the piston can be slipped quickly into the cylinder so that the oil does not escape. It is preferable, before carrying out this procedure, also to oil the rings.

When first starting up, after fitting the cylinder head, it is advisable to leave out the water and to run the engine for a few revolutions until the cylinder heads and bolts are fairly warm, then give the bolts a final pull down and fill the radiator with water in the usual manner. It is, of course, essential that the cylinder should not be allowed to become to hot during the initial run without water, as this is only a question of making them warm.

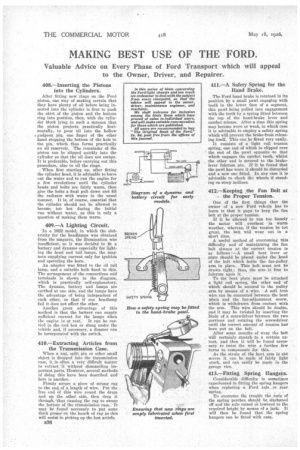

409.—A Lighting Circuit.

In a 1922 model, in which the elettricity for the headlamps was obtained from the magneto, the illumination was insufficient, so it was decided to fit a battery and dynamo especially for. light

big the head and tail lamps, the magneto supplying current only for ignition and operating the horn.

An adapter was fitted to the oil tail lamp, and a suitable bulb fixed in this. The arrangement of the connections mid terminals is shown in the diagram, which is practically self-explanatory. The dynamo, battery and lamps are earthed at one side, and the lamps have the advantage of being independent of each other, so that if one headlamp fail it does not affect the other.

Another great advantage of this method is that the battery can supply sufficient current for the lamps when the engine is at rest. It can he carried in the tool box or slung under the vehicle and, if necessary, a dimmer can be incorporated with the switch.

• 410.—Extracting Articles from the Transmission Case.

When a nut, split pin or other small object is dropped into the transmission case, it is often a very difficult /natter to extract it without dismantling important parts. However, several methoda, of doing this have been described and here is another. .

Firmly sebure a piece of strong rag to the, end. of a length of wire. Put the free end of this wire round the arum and up the othet side, then drag it through, thus causing the rag to sweep the bottom of the transmission case:. It may be found necessaiy to put some thick grEvase ott the.bunch of rag as thiS will assist in picking up the lost article. 411.—A Safety Spring for the Hand Brake.

The Ford hand brake is retained in its position by a small pawl engaging with teeth in the lower face of a segment, this pawl being pulled into engagement with the teeth by a spring fitted between the top of the band-brake lever and ratchet release. After a time this spring may become worn or weak, in which ease it is advisable to employ a safety spring which will prevent the brake from releasing itself. This can be fitted very easily.

It consists of a light coil tension spring, one end of which is clipped over the end of the pawl opposite to that whichengages the ratchet teeth, whilst the other end is secured to the brakelever fulcrum pin. If it be found that the pawl has worn it should be discarded and a new one fitted. In any case it is advisable to chock th,.; wheels if standing on steep inclines.

412.—Keeping ,the Fan Belt at • the Proper Tension.

One of the first things that the owner of a new Ford veh,cle has to learn is that it pays to keep the fan belt at the proper tension. If it be allowed to run too loosely the inotor will overheat in warm weather, whereas, if the tension be too great, the belt will wear out in a short time.

A .useful method of overcoming this difficulty and of maintaining the fan belt always at the correct tension is

as follows small bent lever or plate .should be placed under the...head of the bolt which bolds the fan-pulley arm in place. This bolt mast not be drawn tight; thus, the arm is free to fulcrum upon it.

To the bent plate must be attached a light coil spring, the other end of which should be secured to the pulley arm by means of a wire. A soft iron wire can be connected between the bent qilate and the fan-adjustment screw, which is withdrawn from contact with the arm. This wire should be double, and it 'may be twisted by inserting the blade of a screwdriver between the two portions and rotating the screwdriver until the correct amount of tension has been put on the belt.

After some months of wear the belt certainly stretch to a certain extent, and then it will be found necessary to twist the wire a further few turns to compensate for this.

As the strain of the bent arm is nbt severe it can be made of fairly light stock, and can easily be made in the garage vice.

413.—Fitting Spring Hangers.

Considerable difficulty is • sometimes experienced in fitting the spring hangers when replacing a Ford axle.. or..rear spring.

To overcome the tronble the flirts of the spring perches should fie. slackened off and the axle raised or lowered to the required height by means of a jack It will then be found that .the spring hangers can be fitted with ease.