Levy on B.T.C. Traffic

Page 61

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

WITH -an intimate knowledge of the working of the " fuel-rationing scheme, as it affects commercial road transport and particularly Aand B-licensed operators, it is very apparent to me that there is going to be widespread hardship, due to the disturbance of normal business operation amongst a large number of professional hauliers, many of whom are small family concerns.

The Government must be well aware of the position: they must realize that great numbers of people are going to suffer heavy financial loss and many will undoubtedly 'be driven to bankruptcy. Yet, in these circumstances, no similar proposal to the ' levy " which was imposed to ameliorate the hardship on the British Transport Commission, due to the disturbance caused by denationalization, has been proposed for private operators.

A levy should not only be proposed, it should be accepted immediately, so that the burden of rationing could be evenly spread. That on the revenues of the British Transport Commission should be announced forthwith, to be applied to alleviate cases of hardship, due to the transfer of large blocks of hauliers' business to British Railways and canals.

Grimsby. D. H. McVEIGH, Director, McVeigh Transport, Ltd.

A Bold Idea for Compensation

THE Government sold the ex-B.R.S. A-licence vehicles

I on a five-year-go-anywhere guarantee. As they cannot now "go anywhere," because of the lack of fuel, the buyers should, in my view, be paid compensation by the Government accordingly. There may be a legal liability to do so, but even if not, there is a moral responsibility.

With the huge Budget surplus the Government will probably have, to divert a few million pounds ex gratia to save these people from undeserved loss, perhaps bankruptcy, would_ cost the Treasury nothing, and is surely the least the Government should do in the circumstances, Birmingham, 18. E. J. ANDREWS, A.M.Inst.T.A., Director and Manager, Andrews and Lambert, Ltd.

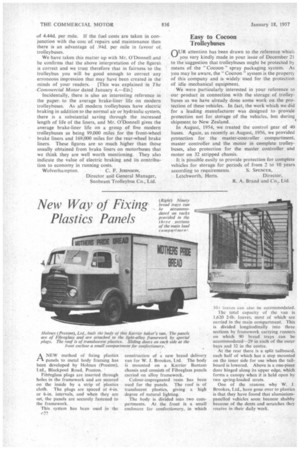

Use of Plastics in Road Transport

mR. H. V. BLAKE (The Commercial Motor, January

11) considers that my paper on "The Use of Plastics in Road Transport," given before the Institute of Road Transport Engineers, is unfair in its criticism. May I deal with his answers to some of my points.

(a) Mr. Blake: The glass-fibre and resin suppliers, far from exaggerating the ease of manufacture, have been at some pains to point out that skilled and experienced supervision is required.

Self: I maintain that up to 1954 an unrealistic picture was given to all industries, either by direct insistence that the processes were simple or by withholding information, or—what is most important— through lack of knowledge due to paucity of technical research. That the picture is now changed is of considerable comfort to me. (See final paragraph to this letter.) (b) Mr. Blake: The mixing and handling of resins certainly require care, but are no more difficult or hazardous than with many other industrial chemicals, such as paint, once the correct procedure has been explained.

Self: ..I agree absolutely. But the correct procedure for safety has very rarely been fully explained. What is wanted is the factory properly laid out in a chemical engineering manner. The reader can get excellent information on this problem from a paper given by Mr. J. R. McCullough, of the safety department, The Budd Company, U.S.A., entitled "Safety Procedures in the Reinforced Plastics Plant." I hope to publish this in the journal Plastics.

(c) Mr. Blake: The hand-lay-up contact-moulding method so widely used in Britain at present may seem crude to scientific eyes. It does, however, produce surprisingly good results when properly done, and most of the production mouldings made today are sound and satisfactory for their purpose.

Self: The methods are crude to the technical and scientific eye. It is true that "good " results are produced when the work is " properly done," but 1 deny that an engineering job approaching metal sheet—that is, with every square inch of the structure as strong as the next—can be achieved using a paint brush or handrollers for impregnation. I submit that acloser approach to the " ideal " can be achieved.

Perhaps the best indication of the urgent need for a technical reorientation of the subject, of the care to be taken and of the.peed for qualified workers, is the welcome step taken by one of the largest manufacturers of polyester resins at the beginning of 1956: British Industrial Plastics, Ltd.. Oldbury, instituted a school for the training of workers in the field of glass-fibre reinforcements, the training including experience in the lay-up technique, in the working of the preforming machine, the rubber-bag pressure technique, the matched-moulds process and the use of low-pressure presses; Only by the spread of such training will the industry reach a desired standard of technology.

London.. E.C.1. M. D. CURWEN_

Economics of .Trolleybus Operation

WE notice on page 671 of your issue dated December 14, 1956, reference to the paper recently read before an East Regional Centre meeting of the Institute of Road Transport Engineers by Mr. T. P. O'Donnell, general manager, Ashton-under-Lyne Transport Department'.

In your comments you state, as an extract from this paper, that municipally owned passenger transport running costs averaged 4.44d. per mile for trolleybuses, compared with 4d. per mile for motorbuses; and that there was an advantage of 1.38d. per mile to trolleybuses in the cost of electric power.

In reading this it does not appear clear that the figures of 4.44d. and 4d. per mile relate solely to the cost of all repairs and maintenance and did not include the cost of the electric power for the trolleybuses or oil fuel for the motorbuses, so that the advantage of 1.38d. per mile has not been taken into account in arriving at the ftgure

of 4.44d. per mile. If the fuel costs are taken in conjunction with the cost of repairs and maintenance then there is an advantage of .94d. per mile in favour of trolleybuses. We have taken this matter up with Mr. O'Donnell and he confirms that the above interpretation of the figures is correct and we trust therefore that in fairness to the trolleybus you will be good enough to correct any erroneous impression that may have been created in the

minds of your readers. [This was explained in The -Commercial Motor dated January 4.—ED.] Incidentally, there is also an interesting reference in the paper, to the average brake-liner life on modern trolleybuses. As all modern trolleybuses have electric braking in addition to the normal air or hydraulic system, there is a substantial saving through the increased length of life of the liners, and Mr. O'Donnell gives the average brake-liner life on a group of five modern trolleybuses as being 99,000 miles for the front-wheel brake liners and 169,000 miles for the rear-wheel brake liners. These figures are so much higher than those usually obtained from brake liners on motorbuses that we think they are well worth mentioning. They also indicate the value of electric braking and its contribution to economy in running costs.

Wolverhampton. C. F. JOHNSON,

Director and General Manager, Sunbeam Trolleybus Co., Ltd.

Easy to Cocoon Trolleybuses

nUR attention has been drawn to the reference which you very kindly made in your issue of December 21 to the suggestion that trolleybuses might be protected by means of the " Cocoon " spray packaging system. As you may be aware, the " Cocoon " system is the property of this company and is widely used for the protection of idle mechanical equipment.

We were particularly interested in your reference to our product in connection with the storage of trolleybuses as we have already done some work on the protection of these vehicles. In fact, the work which we did for a leading manufacturer was designed to provide protection not for storage of the vehicles, but during shipment to New Zealand. In August, 1954, we treated the control gear of 40 buses. Again, as recently as August, 1956, we provided protection for the master-controller compartment, master controller and the motor in complete trolleybuses, also protection for the master controller and motor on 32 stripped chassis. It is pbssible easily to provide protection for complete vehicles for storage for periods of from 2 to 10 years

according to requirements. S. SPENCER,

Letchworth, Herts. Director, R. A. Brand and Co., Ltd.