THE ART OF ROPING LOADS.

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Some Useful Notes on a Subject about which but Little Information has Hitherto been Available.

MUCH of the efficiencyin any form of transport depends upon how the goods carried are stowed, and how, once in position on a vehicle, they are retained there for the duration of the journey, and this applies with even more importance to the road transport vehicle than in the case of other means for conveyance.

A man who is expert at roping loads into position can save a great amount of time both in loading and unloading and, what is perhaps more important still, In so securing the goods that they do not shift on the vehicle during transit and are consequently far less liable to become damaged or to be lost. It is quite a frequent occurrence for articles, both large and small, to be found in the road. In many eases the attention of the driver is drawn to the loss before too late, but in other instances the goods are irrecoverable. If properly packed and secured on all occasions, such losses would seldom or never occur.

Effectually to deal with goods which may be of most awkward shapes, it is most essential to possess or to gain some knowledge of knots, and those who do not already possess this will, we believe, find our illustra

tions most useful in this connection. The subject is one that has had very little attention paid to it, and the notes from which we have prepared this article have been submitted to us by one of our readers who appears to have given much thought to the secure and tidy manner in which he utilizes and carries his tackle.

He points out that the average driver either throws his ropes slipshod on Ito his lorry or puts them on the footboards in the cab. As an improvement on this, in the first place it will be found advisable to make a number of useful hooks by bending pieces of iron or mild-steel rod into the form shown in one of our drawings. These can be hooked under the channel side-members of the chassis frame, so that ropes can be attached wherever necessary. All ropes should be neatly looped and carry an iron ring, or, if thought more advisable, heart-shaped or round thimbles can be employed, and these would perhaps appeal more to the man with rather more knowledge of ropes and roping than is usual. Advice on the arranging of these thimbles can always be obtained from some sailor friend.

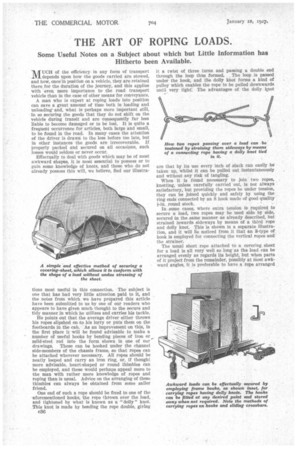

One end of such a rope should be fixed to one of the aforementioned hooks, the rope thrown over the load, and tightened by what is known as a 'dolly" knot. This knot is made by bending the rope double, giving

c36 It a twist of three turns and passing a double end through the loop thus formed. The loop is passed under the hook, and the dolly knot forms a kind of pulley which enables the rope to be pulled downwards until very tight: The advantages of the dolly knot

are that by its use every inch of slack can easily be taken up, whilst it can be pulled out instantaneously and without any risk of tangling.

When it is found necessary to join two ropes, knotting, unless carefully carried out, is not always satisfactory, but providing the ropes be under tension, they can be joined quickly and safely by using the ring ends connected by an S hook made of good quality Fin. round stock.

In some cases, where extra tension is required to secure a load, two ropes may be used side by side, secured in the same manner as already described, but strained inwards sideways by means of a third rope and dolly knot. This is shown in a separate illustration, and it will be noticed from it that an S-type of hook is employed for connecting the vertical ropes and the strainer.

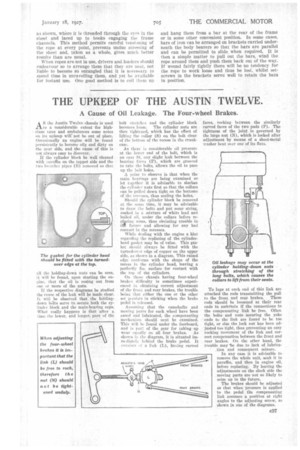

The usual short rope attached to a covering sheet for a load is all very well so long as the load can be arranged evenly as regards its height, but when parts of it project from the remainder, possibly at most awkward angles, it is preferable to have a rope arranged

as shown, where it is threaded through the eyes in the sheet and laced up to hooks engaging the frame channels. This method permits careful tensioning of the rope at every point, prevents undue stressing of the sheet and, taken as a whole, gives . much better results than are usual.

When ropes are not in use, drivers and loaders should endeavour so to arrange them that they are neat, not liable to become so entangled that it is necessary to spend time in unravelling them, and yet be available for instant use. One good method is to coil them up and hang them from a bar at the rear of the frame or in some other convenient position. In some cases, bars of iron can be arranged on brackets carried underneath the body bearers so that the bars are parallel and can be permitted to slide when required. It is then a simple matter to pull out the bars, wind the rope around them and push them back out of the way. If wound fairly tightly there will be no tendency for the rope to work loose and thus be lost, whilst setscrews in the brackets serve well to retain the bars in position.