EW SMALL OIL TINES

Page 52

Page 53

Page 54

Page 55

If you've noticed an error in this article please click here to report it so we can fix it.

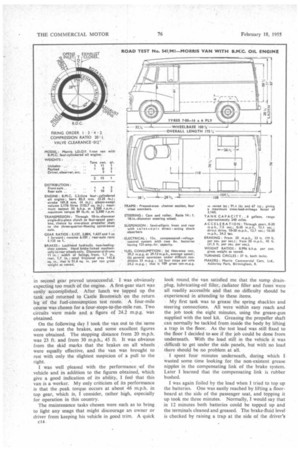

with 2.2-litre Oil Economical and tam: 33 m.p,g.. ; 92-mile Test T. .HE highlight of my test of the Morrls-Commercial 14on van was a run of 14 miles in 24 minutes, an average speed of 35' m.p.h. with full load; Frequently the van was travelling at a speed of well _over 50 m.p.h., but it held the road well, with the B.M.C. .2.2-litre oil engine sounding as if it were enjoying every

moment. .

• . This fast trip; ;which was on the A41 road from Warmington to Warwick, served to demonstrate what could be expected from this vehicle when operated over-. seas, where a speedy and safe vehicle of this type would not be -hampered bYa low speed limit. The figure of 33 -m.p.g., which was obtained during an arduous test of 92 miles, indicates that the B.M.C. oil engine is also Most economical. .

The chassis which, in its standard form, is powered by a 2.2-litre petrol engine, is conventional in design. Except for the name plate and the radiator grille, it is similar in all its other features, whether it he marketed by the Austin or Morris organization.

The B.M.C. oil engine is of the indirect-injection, four-stroke type and develops 55 b.h.p. at 3,500 r.p.m., a speed which is the highest maximum of any fourstroke oil engine currently in use in this country. The advantage of its wide speed range was appreciated on the fast run to which reference has been made.

Maximum torque of 89 lb.-ft. is developed at 2,500 r.p.m. The compression ratio is 20 to 1, and the combustion chamber is of the Ricardo Comet III-type, with C.A.V. pintaux injectors.

Heater plugs are provided and a hand-set excess-fuel device is fitted to aid starting under conditions of extreme cold. Full details of this engine were given in The Commercial Motor on September 17, 1954.

It was a dull and damp day when 1 left the works at Adderley Park, acc6rnpanied by Mr. R. Gifford, Morris-Commercial proving engineer, at the wheel of the fully laden van. We had been travelling for less than a mile when a loud clatter from the engine indicated el2 that a nozzle needle had stuck open. As is often the case with these injectors, it soon freed itself after the engine had been revved up slightly on light load.

iPanic over, we continued on our way to Hall Road, Castle Bromwich, where we stopped to top up the auxiliary and main tanks before setting off on the first fuel-consumption run through Kenilworth to Warwick.

During the first few miles, traffic conditions delayed our progress, but, once through Stonebridge, however, the road was fairly quiet and we maintained a steady speed of about 30 m.p.h. until we reached Kenilworth, 32 minutes after leaving Hall Road. Here the mileometer showed that we had covered 1-5 miles, the average speed thus being 28 m.p.h.

On the run to Warwick, which was reached in 46 minutes, we had two stops for traffie and the indirect gears were used on five occasions. It was found that 0.54 gallons of fuel were required to top up the auxiliary tank, which represented a fuelconsumption rate of 41.7 m.p.g. at an average speed of 27.4 m.p.h.

Later in the day this route was covered in the opposite direction. On this'occasion the average speed worked out at 30.8 m.p.h., with a fuel-consumption rate of 36.3 m.p.g.

Thus, the respective averages for the total journey were 39.3 m.p.g. and 29.13 m.p.h.

Acceleration tests were carried out on a level stretch of the Warwick-Banbury road, the vehicle putting up a creditable performance. Passing through the gears, 20 m.p.h. was reached in 7.5 sec. and 30 m.p.h. in 15.1 sec. In direct drive, 12.1 sec. were required to accelerate from 10 to 20 m.p.h. and 24.2 sec. from 10 m.p.h. to 30 m.p.h.

Ron Gifford drove to Warmington, and I had ample opportunity to study the general features of the

p HIS I road routine carried Motor" As the can be n tant as additiotu greatly I van. Its wide, deep windscreen gives excellent forward vision and the two windscreen wipers sweep an ample arc on both sections of the screen. On the instrument board are a speedometer, fuel gauge, ammeter and oil-pressure gauge.

When I drove the vehicle I found the driving position comfortable, controls easy to handle and the rear-view mirror well iced, although I would have appreciated an interior rror, even if vision through the rear window would 'netimes be obscured by the load. As the driver can t his head out of the cab, reversing is simplified, but lid not like the look of the vicious window-lock, which liable to catch the driver's car.

k useful feature of the van body is found in its low, t-topped wheel-boxes. A total capacity of 235 cu. ft. available for the load, and the rear doors, which d against the side of the van, are thus well clear ten the van is being loaded. The sliding side doors are certainly an asset, and although I made many exits and entrances during the tests, I could find nothing to criticize in respect of the access provided to either seat.

On arrival at War mington we took' a run at the hill at 35 m.p.h. When the speed had fallen to 28 'm.p.h., third gear was engaged and on the steepest part of the hill, where the gradient is about 1 in 7.5, second gear was necessary for a short distance. At this point the road speed fell to about 10 m.p.h.

Standing-starts were made on different parts of the hill and the engine was quite ready to take the vehicle away on the steepest sections. The hand brake proved itself capable of holding the vehicle on a 1 in 6 section of a side road, but attempts to get away on this section

in second gear proved unsuccessful. I. was obviously expecting too much of the engine. A first-gear start was easily accomplished. After lunch we topped up the tank and returned to Castle Bromwich on the return leg of the fuel-consumption test route. A four-mile course was chosen for a four-stops-to-the-mile run. Two circuits were made and, a figure of 24.2 m.p.g. was obtained.

On the following day I took the van out to the same course to test the brakes, and some excellent figures were obtained. The stopping distance from 20 m.p.h. was 23 ft. and from 30 m.p.h., 45 ft. It was obvious from the skid marks that the brakes on all wheels were equally effective, and the van was brought to rest with only the slightest suspicion of a pull to the right.

I was well pleased with the performance of the vehicle and in addition to the figures obtained, which give a good indication of its ability, I feel that this van is a worker. My only criticism of its performance is that the peak torque occurs at about 46 m.p.h. in top gear, which is, I consider, rather high, especially for operation in this country.

The maintenance tasks chosen were such as to bring to light any snags that might discourage an owner or driver from keeping his vehicle in good trim. A quick c14 look round, the van satisfied me that the sump drainplug, lubricating-oil filler, radiator filler and fuses were all readily accessible and that no difficulty should be experienced in attending to these items.

My first task was to grease the spring shackles and steering connections. All were within easy reach and the job took rue eight minutes, using the grease-gun supplied with the tool kit. Greasing the propeller shaft can normally be tackled from inside the body by lifting a trap in the floor. As the test load was still fixed to the floor I decided to see if the job could be done from underneath. With the load still in the vehicle it was difficult to get under the side panels, but with no load there should be no problem at all.

I spent four minutes underneath, during which I wasted some time looking for, the non-existent grease nipples in the compensating link of the brake system. Later I learned that the compensating link is rubber bushed.

I was again foiled by the load when I tried to top up the batteries. One was easily reached by lifting a floorboard at the side of the passenger seat, and topping it up took me three minutes. Normally, I would say that in 12 minutes both batteries could be topped up and the terminals cleaned and greased. The brake-fluid level is checked by raising a trap at the side of the driver's it, and filling the master cylinder to the required lev.J ces only a moment.

Turning to the engine, I found that no complications involved in removing the injectors for checking. This should not take more than Lt hours, if no adjust:nt to the injectors is required. Setting the tappet !a ranee is .another job that depends on the amount adjusting found necessary. The engine on the 'test n had all clearances correctly set, but I took good note the fact that each rocker is accessible and adjusting Nn should be easy.

A Snag Encountered Trouble started when I came to renew the paper ;ment of the C.A.V. fuel filter, 1, had observed that :.re appeared to be little chance of getting the filter wl out without first removing the fuel-outlet nnection.

Nevertheless. I thought it was worth trying, but as an as the central securing nut was free the bowl slipped )m my grasp. I therefore removed the outlet conneein and also the lead to No. I cylinder heater plug. is made no difference, however, as I still could not I the bowl past the heater plugs, injectors and their ;ociated wires' and pipes.

By tilting the bowl, I eventually managed to extract element and fit a new one. Possibly the complete .er can be removed, but as there is room for mounting on the near side of the engine where it would be easy remove the sludge bowl, 1 feel that there is good ison for criticizing its present location on the front ' side of the engine block.

Removing the lubricating-oil filter was the essence of simplicity. It took me only six minutes to replace the cartridge, and this included running the engine to refill the filter and topping-up the sump to the usual level. My remaining tasks of adjusting the brakes and changing the wheel were combined in one operation on this vehicle, as the wheels must be removed to reveal the brake-shoe Mier= adjusters.

Using the jack and wheelbrace provided on the vehicle, it took me 18 minutes to fit the spare to the rear off-side wheel and adjust the brake. Leaving out the time for removing and replacing the spare wheel, adjusting' the brakes all round would take just about an hour. Fitting the spare wheel involved no complications and normally the job should not take more than 20 minutes, even with the van loaded and using the vehicle's small screw-type jack.

I was left with the impression that once the fuel filter is made more accessible, servicing the 1-ton van will not bother anyone. A useful instruction book is available for every driver, and soon a handbook on the B.M.C. 2.2-litre engine will be ready.

Extra Cost Recouped I have not had the opportunity of testing a petrolengined version of this van, but it is safe to assume that the extra cost of £115 for the oil engine will soon be recouped, in view of the very much lower fuel-consurnption rate which is obtained, as -compared with the petrol

engine, without any loss of performance. '

spent two days with this vehicle, testing it on the road, examining its mechanical features and servicing it, and I am certain that it is a vehicle that any operator will be pleased to have in his fleet.