FEEDING FRENZY

Page 49

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

Want turkey, stuffing and your cracker in p on Christmas Day? Tim Maughan sees 1 these wishes can only come true with HC

Christmas is the time for merriment, drinking— and eating.Turkey,parsnips, cranberry sauce,mince pies,stuffing: from the most humble homes to palatial residences,25 December is the time for feasting. 3663 specialises in delivering food, and the firm drops its goods to locations as prestigious as Buckingham Palace,Chelsea Football Club. and the finest London hotels.

A visit to the firm's Battersea depot takes us to a predominantly residential area. Bricked streets stand row after row and, among them, nestles 3663's base. Inevitably, people from these houses will,at some time or another, end up eating some of this company's produce.

The company plays a pivotal part in UK food distribution. Its fleet of 960 trucks and vans serves "clubs, pubs. hotels and restaurants" across the country, says Phil Townsend, transport manager at Battersea:This is an own-account operation on an imps The company buys its food and drin Christmas crackers! — and then sells ers,them to the catering trade."We everything from soups to tinned tor sliced ham to cheeses," reports Tow On the day we visit.coltunns of IN trucks mean there's no room to swii (a cat's definitely out of the questiol yard. Other operators bring in the p a daily basis, and these firms held ar physical laws appear to be compror Santa Claus and his reindeer would to find room to drop here. How dot successfully deliver the food?

Military precision is the key. A tyi goes thus: operators drop foodstuff depot up until 2pm.All day. 3663 tel staff secure deals with caterers. By 4 all orders are placed.The picking an process begins. At Sam the following day, the 35-strong Battersea fleet leaves the depot. The vehicles do not return until late afternoon — and that means the yard is empty, allowing the artics to swing in and deposit their goods. Once a week, a 3663 artic from the firm's Reading RDC also delivers food to the yard.

There are three storage areas:a 2,700m2 warehouse, a 820m2 chiller, and a freezer with room to accommodate 35 pallets. CM cannot resist a brief spell in the -24`C "Ice Station Zebra" confines of the freezer —brief being the word. Luckily,Townsend and Colin Chapman. operations manager, successfully negotiate the facility's heavy door and lead us into the relatively "tropical" confines of the chiller. With a temperature range from 0°C to 5°C. this zone is used to store sliced meats,yoghurts and such like.

In the main warehouse, a seasonal feel is more apparent. We glimpse cranberry sauce and Christmas crackers. "We also stock table cloths, party poppers, hats, t urkeys and novelty Christmas chocolates:" explains Chapman."We sell more turkey products in November and December than we do all year round," he adds.

One "unit", in 3663 parlance, refers to a box of a particular product. So one unit could mean a batch of sugar,flour or teabags. On a typical day, some l 8,000 units are dispatched from this depot. Come the Christmas build-up (which begins in October) that figure increases to 26,000 units.

Immaculate planning and canny use of resources are vital, especially in the run-up to 25 December. Townsend says: "We can isolate slow moving stock here and send it to our Reading RDC to make space for other units. On a daily basis,our routeing clerk Richard Capes interrogates the routeing system."

London regulations

His use of the word "interrogates" sounds dramatic, but it's well chosen. HGV movements must be intricately scrutinised. The Battersea base covers all the central London postcodes, and stretches much further out, from Richmond in the extreme south-west of the metropolis to Eltham in the south-east.

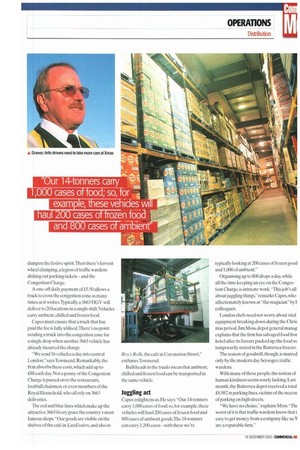

The inner city multi-drop work is unlike any other UK high street delivery operation.This is London.The Lorry Ban, the sheer volume of traffic and aggressive driving all conspire to dampen the festive spirit.Then there's fervent wheel clamping, a legion of traffic wardens dishing out parking tickets— and the Congestion Charge.

A one-off daily payment of £5.50 allows a truck to cross the congestion zone as many times as it wishes. Typically. a 3663 HGV will deliver to 20 locations in a single shift.Vehicles carry ambient, chilled and frozen food.

Capes must ensure that a truck that has paid the fee is fully utilised.There's no point sending a truck into the congestion zone for a single drop when another 3663 vehicle has already incurred the charge.

"We send 16 vehicles a day into central London." says Townsend. Remarkably, the firm absorbs these costs, which add up to £88 each day. Not a penny of the Congestion Charge is passed on to the restaurants, football chairmen. or even members of the Royal Household. who all rely on 3663 deliveries.

The red and blue lines which make up the attractive 3663 livery grace the country's most famous shops. Our goods are visible on the shelves of the café in EastEnders, and also in Roy 's Rolls, the café in Coronation Street,enthuses Townsend.

Bulkheads in the trucks mean that ambient, chilled and frozen food can be transported in the same vehicle.

Juggling act

Capes enlightens us. He says:"Our 14-tonners carry 1,000 cases of food; so, for example, these vehicles will haul 200 cases of frozen food and 800 cases of ambient goods.The 18-tormers can carry 1,200 cases — with these we're typically looking at 200 cases of frozen good and 1,000 of ambient."

Organising up to 800 drops a day. while all the time keeping an eye on the Congestion Charge. is intricate work."This job's all about juggling things," remarks Capes, who affectionately known as 'themagician" by ii colleagues.

London chefs need not worry about vital equipment breaking down during the Chris mas period. Jim Moss, depot general manag explains that the firm has salvaged food fror hotel after its freezer packed up; the food Viik temporarily stored in the Battersea freezer.

The season of goodwill. though. is marred only by the modem day Scrooges: traffic wardens.

With many of these people, the notion of human kindness seems sorely lacking. Last month, the Battersea depot received a total £8,982 in parking fines, victims of the necess of parking on high streets.

"We have no choice," explains Moss."Tlu worst of it is that traffic wardens know that i easy to get money from a company like us.V are a reputable firm." From the traffic warden's point of view, cars bearing outdated tax discs may be more hassle than they are worth, he argues."A well known firm like 3663." says Moss,"is guaranteed to come up with the money. We are just trying to keep the hotel and catering industry fed." he asserts.

Waitrose is a supermarket chain with 143 branches located in the south of England. East Anglia. the Midlands and Wales. Like 3663, its livery is pleasant on the eye like much of its food it's a vital looking light green.

And, again like 3663, it runs its own trucks. The company operates 125 tractive units, five rigids,and 230 box trailers, which are chiefly reefers. Hays Logistics provides transport for the remainder of the company's distribution needs.

Wait rose's units are based in Bracknell. Berkshire. HGVs constitute just one dimen sion of the Bracknell operation: the head offices are located here, as is a major RDC.

Dave Stringer used to drive Waitrose trucks himself."I started as an artic driver 18 years ago;10 years ago I got involved in office work.! progressed from section, then to shift manager. and from there to deputy transport manager."

Along the way he secured his CPC. Today he is Bracknell's transport manager. "We are very much a 24-hour operation. In fact Christmas Day and Easter Sunday are the only days that we don't work."

From farm to table

Bear in mind that the delicious Waitrose fayre is safely stored in household kitchens on Christmas Eve, or at least it should be. By then. turkeys. sauces, vegetables. drinks and the like have completed the supplier/RDC/ supermarket/kitchen excursion.

Let's rewind through the process and see how the piping hot Christmas dinner reached that table in Acacia Avenue.

Suppliers grow their vegetables, rear their turkeys, brew their alesand then the products are hauled to the Bracknell RDC by other operators. Milk.poultry.fish and yoghurts are stored in the chilled warehouse, which is maintained at 2 C.This facility is large, with a workforce of 220 personnel.A single shift involves 60 people.

John Catling, ambient shift manager. says suppliers have lobe punctual when dropping at the chilled department."If they were not on time then we would not be able to work," he states.

An astonishing 80.000 turkeys will pass through this warehouse in the build-up to Christmas.They are stored in gas sealed bags.

Phil Wirnsett. fresh food manager. warehouse, points out that this staple festive dish is gradually losing ground to other foods. Beef is becoming increasingly popular, he says.

Every week, there are 2,000 truck movements from the RDC to the supermarkets. Stringer explains how the process works. He says: "This is very much a fresh food company. When the ambient goods come in to Bracknell there is no rush to transport them.

"But when the fresh foods come in.it is important that they are delivered quickly. We have what we call the 'first wave' short-life foods. Every Waitrose branch gets a delivery of these foods by 7.30am, which gives the supermarket staff sufficient time to put the produce on the shelves.

'The 'second wave' foods are longer-life fresh produce such as cheese.These must be in the branches by 5pm.The ambient goods, the dried and tinned food,can be delivered at any time."

Waitrose trucks run at a maximum of 31 tonnes, and the HGVs are predominantly Dafs and Volvos.The own-account nature of the operation means there is no pressure from customers to run at heavier weights.

By September,volumes of food start to increase. "Christmas crackers go into the shops in November, along with ambient goods such as wines and spirits.The weekend before Christmas is traditionally manic," says Stringer. "We have to get extra vehicles in to deal with the higher volumes."

Typically, 35 agency drivers are taken onto help manage the rush. Fresh and ambient food is dropped at branches right up to Christmas Eve. At hectic periods such as these, there are no fewer than four section managers in the transport office at any one time.

Christmas chaos

Mick Graves. driver trainer at Bracknell, tells us that as Christmas gets closer Waitrose customers can become a little excited: artic drivers need to watch out for motorists dashing around near supermarkets.

At Waitrose's Wokingham, Berkshire store, the branch's scissorlift rises to collect a consignment of fizzy drinks from an artic, while warehouse staff push food-laden trolleys to and fro.

It's a metallic, trundling wall of sound ur that is, we push through the swing doors or the supermarket Hour. Peace. Shoppers an around, oblivious to the heavy machinery truck behind the scenes.

The interior is surgically clean, the Waitrose staff smart, the food beautifully presented. Mark Hicks, Wokingham depa ment manager. says that last year his store 2,000 turkeysmore than any other branc "Stock is ordered by an automated orderii system; this projects and predicts exactly v we need.

Unlike the 3663 Battersea ileet,Waitroi.. HGVs perform one drop, delivering the entire box-load to a single supermarket.T Wokingham branch usually receives five II a day. As the festive madness approaches t will climb to eight, as truck after truck fee( our consumer appetites. IN