Shock free maintenance

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

Steve Gray turns his thoughts to dampers

MAY SEEM strange that !hide manufacturers fit rings and then go to great igths to slow down their tion. However, there are od reasons for this as I disIvered during a visit to rtomotive Products at Baniry to find out more about a vice that's often taken for anted — the damper.

Alt -lough AP doesn't actually 3nulacture dampers (or shock

■ sorbers if you prefer) it does arket them under its Lockheed tcle mark. Being jealous of the Jali.y reputation this trade ime has acquired, AP insists at its engineers have an innate knowledge of the worng of any components it sells Jt doesn't necessarily anufacture.

Basically, there are two kinds damper, the lever arm type id the telescopic. Both are fit d to a vehicle for the same ason to reduce the frequency the spring.

In addition there must be a !lance in frequency between e front and rear of the vehicle, it would tend to rock around ; central axis. The same is true side to side movement. As ell as tending to make the iver feel queasy, unnecessary ady roll is also potentially 3ngerous, upsetting the abil ty of the vehicle.

Finally, dampers stop nose diving which is again an unstable condition, and which tends to lift the load off the rear wheels thus losing either braking grip or traction.

One important point is that the dampers must be tuned to each individual vehicle's characteristics so they are able to suit its ride and handling, its spring rate and changes in temperature.

Modern lorries which have been designed to provide a greater degree of driver comfort by having softer springs tend to have larger wheel movements. If these movements weren't regulated, as each wheel hit a bump it would move up to cope with the change in surface, but would tend to carry on moving.

The damper controls this movement and keeps the wheel in contact with the ground. However, the speed with which it moves up as It accepts the bump must be different to that when the wheel is going down. Thus dampers are velocity sensitive.

How then do the manufacturers set about making the damper work practically?

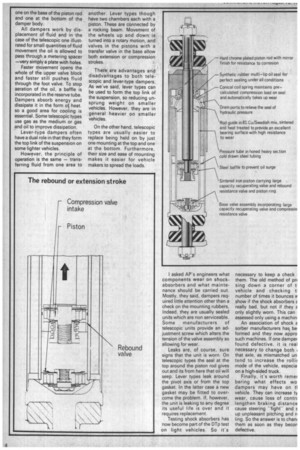

Most of them are either two or three stages. Taking the telescopic type first, if we were to look at one in cross-section (see diagram) it can be seen that there are two valve assemblies, one on the base of the piston rod and one at the bottom of the damper body.

All dampers work by displacement of fluid and in the case of the telescopic one illustrated for small quantities of fluid movement the oil is allowed to pass through a metering spacer —very simply a plate with holes.

Faster movement opens the whole of the upper valve block and faster still pushes fluid through the foot valve. To stop aeration of the oil, a baffle is incorporated in the reserve tube. Dampers absorb energy and dissipate it in the form ol heat. so a good area for cooling is essential. Some telescopic types use gas as the medium or gas and oil to improve dissipation.

Lever-type dampers often have a dual role in that they form the top link of the suspension on some lighter vehicles.

However, the principle of operation is the same — transferring fluid from one area to another. Lever types though have two chambers each with a piston. These are connected by a rocking beam. Movement of the wheels up and down is turned into a rotary motion, and valves in the pistons with a transfer valve in the base allow both extension or compression strokes.

There are advantages and disadvantages to both telescopic and lever-type dampers. As we've said, lever types can be used to form the top link of the suspension, so reducing unsprung weight on smaller vehicles. However, they are in general heavier on smaller vehicles.

On the other hand, telescopic types are usually easier to replace being held on by just one mounting at the top and one at the bottom. Furthermore, their size and ease of mounting makes it easier for vehicle makers to spread the loads.

I asked AP's engineers what components wear on shockabsorbers and what maintenance should be carried out. Mostly, they said, dampers required little attention other than a check on the mounting rubbers, Indeed, they are usually sealed units which are non serviceable. Some manufacturers of telescopic units provide an adjustment screw which alters the tension of the valve assembly so allowing for wear.

Leaks are, of course, sure signs that the unit is worn. On telescopic types the seal at the top around the piston rod gives out and its from here that oil will seep. Lever types leak around the pivot axis or from the top gasket. In the latter case a new gasket may be fitted to overcome the problem. If, however, the unit is leaking to any degree its useful life is over and it requires replacement.

Testing shock absorbers has now become part of the DTp test on light vehicles. So it's necessary to keep a check them. The old method of pri sing down a corner of t vehicle and checking t number of times it bounces v show if the shock absorbers E really bad, but not if they E only slightly worn. This can assessed only using a machin, An association of shock E sorber manufacturers has be formed and they now appro such machines. If one damper found defective, it is real necessary to change both 1 that axle, as mismatched un tend to increase the rollir mode of the vehicle, especia on a high-sided truck.

Finally, it's worth rerner bering what effects wo dampers may have on tl vehicle. They can increase ty wear, cause loss of contr.( lengthen braking distance cause steering "fight" and E up unpleasant pitching and r, ling. So the answer is to chan, them as soon as they becor defective.