Rubber eases out chassis ride shock

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

USING rubber instead of steel for the springing on commercial vehicles, particu larly trailers, can offer many advantages to an operator.

For a start maintenance is substantially reduced, as there are no spring shackles to wear, no springs to break or U-bolts to come loose.

Rubber doesn't rust and un like solid leaf spring arrangementS has more "give". This in itself gives the rubber set up two distinct advantages: a smoother ride and less transmission of shock loads to the vehicle chassis frame.

While a smoother ride is not necessarily important to the majority of operators, it is to companies running tankers or carrying expensive cargoes.

Reducing shock loads is however, a major plus point, preventing chassis cracking and the risk of ancillary components vibrating loose.

There are two major manufacturers of rubber sus

pensions, Norde and Rydewell. CM has been looking at what they have to offer and how their systemsvirork.

Norde has been establish now for over seventeen ye and is probably the best kno name in the business. Its syst has solid rubber spring ur which are used in shear a compression and so are adji.. able depending on the lc applied. These rubber un have been designed to ca vertical loads in a progress way.

To cope with lateral loal i.e., braking and accelerati torques, A-frames are us€ These are mounted in the m; frame with rubber bushes a are connected to the axle cen — again with rubber bush' The suspension itself is by pa of inclined solid rubber bond spring units located betwe rigid mounting points on t axle and chassis.

On tandem-axle arran ments the axles are linked b)

are, is a ,od a teral seer b bfra

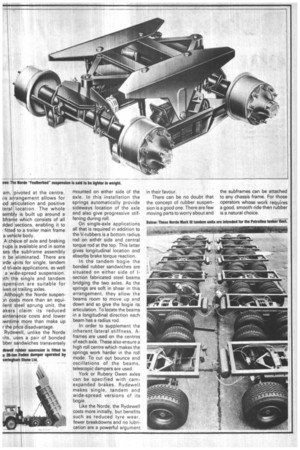

pivoted at the centre. rangement allows for ticulation and positive location. The whole y is built up around a e which consists of all )Ided sections, enabling it to fitted to a trailer main frame a vehicle body.

A chyice of axle and braking t-ups is available and in some ses the subframe assembly n be eliminated. There are )rde tits for single, tandem id tri-a le applications, as well a wide-spread suspension. ath th single and tandem Ispen ion are suitable for iven o trailing axles.

Altho4igh the Norde suspen)n cos s more than an equilent steel sprung unit, the akers claim its reduced ainten nce costs and lower )wntime more than make up r the price disadvantage.

Rydewell, unlike the Norde lits, uses a pair of bonded bber s .ndwiches transversely

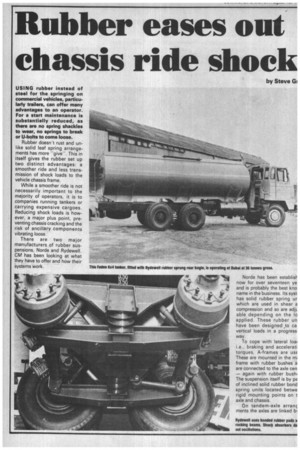

dewell r bber susension is fitted to is 39-ton Foden dumper operated by Iveringha Slone Ltd. mounted on either side of the axle. In this installation the springs automatically provide sideways location of the axle and also give progressive stiffening during roll.

On single-axle applications all that is required in addition to the V-rubbers is a bottom radius rod on either side and central torque rod at the top. This latter gives longitudinal location and absorbs brake torque reaction.

In the tandem bogie the bonded rubber sandwiches are situated on either side of lsection fabricated steel beams bridging the two axles. As the springs are soft in shear in this arrangement, they allow the beams room to move up and down and so give the bogie its articulation. To locate the beams in a longitudinal direction each beam has a radius rod.

In order to supplement the inherent lateral stiffness, Aframes are used on the centres of each axle. These also ensure a high roll centre which makes the springs work harder in the roll mode. To cut out bounce and oscillations of the beams, telescopic dampers are used.

York or Rubery Owen axles can be specified with camexpanded brakes. Rydevvell makes single, tandem and wide-spread versions of its bogie.

Like the Norde, the Rydevvell costs more initially, but benefits such as reduced tyre wear, fewer breakdowns and no lubrication are a powerful argument in their favour.

There can be no doubt that the concept of rubber suspension is a good one. There are few moving parts to worry about and the subframes can be attached to any chassis frame. For those operators whose work requires a good, smooth ride then rubber is a natural choice.