HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble,

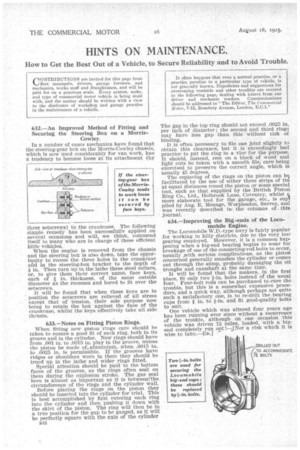

632.—An Improved Method of Fitting and Securing the Steering Box on a MorrisCowley.

In a number of cases mechanics have found that the steering-gear box on the Morris-Cowley chassis, which is now used considerably for van work, has a tendency to become loose at its attachment (by three setscrews) to the crankcase. The following simple remedy has been successfully applied .on several occasions and will, we think, commend itself to many who are in charge of these efficient little vehicles.

When the engine is removed from the chassis and the steering box is also down, take the opportunity to recess the three holes in the crankcase and in the steering-box bracket to the depth of * in. Then turn up in the lathe three steel collars, or, to give them their correct name, face keys, each of I in. thickness, of the same outside diameter as the recesses and bored to fit over the setscrews.

It will be found that when these keys are in position the setscrews are relieved of all stress except that of tension, their sole purpose now being to retain the box against the face of the crankcase, whilst the keys effectively take all side thrusts.

633.—Notes on Fitting Piston Rings.

When fitting new piston rings care should be taken to ensure a good fit of each ring, both in, its groove and in the cylinder. New rings should have from .001 in. to .0015 in. play in the groove, unless the piston be made of. aluminium, when .0015 in. to .0025 in. is permissible. If the grooves have ridges or shoulders worn in them they should be trued up in the lathe and wider rings fitted.

Special attention should be paid to the bottom faces of the grooves, as the rings often seat on them during the explosion stroke. The gas seal here is almost as important as it is betweeathe circumference of the rings and the cylinder wall.

Before placing the rings on the piston they should be inserted into the cylinder for trial. This is best accomplished by first entering each ring into the cylinder and then pushing it down with the skirt of the piston. The ring will then be in a true position for the gap to be gauged, as it will be perfectly square with the axis of the cylinder B12 The gap in the top ring should not exceed .0025 in. per inch of diameter ; the second and third rings may have less gap than this without risk of binding.

It is often necessary to file one joint slightly to obtain this clearance, but it is exceedingly bad practice to put the ring in a vice for the purpose. It should, instead, rest on a block of wood and light cuts be taken with a smooth file, care being exercised to preserve the correct angle, which is usually 45 degrees.

The replacing of the rings on the piston can be facilitated by the use of either three strips of tin at equal distances round the piston or seine special tool, such as that supplied by the .British Piston Ring Co., Ltd., Holbrook Lane, Coventry, whilst 1.1 more elaborate tool for the garage, etc., is sup/ plied by Aug. E. Menuo, Worplesdon, Surrey, and was recently described in the columns of this journal.

634.—Improving the Big -ends of the Locomobile Engine.

The Locornobile W.D.-type lorry is fairly popular for working in hilly districts, due to the very low gearing employed. However, it is a common happening when a big-end bearing begins to wear for breakage of one of the connecting-rod bolts to occur, usually .with serious complications, as the piston concerned generally smashes the cylinder or comes out through the sump, probably damaging the oil troughs and camshaft at the same time. It will be found that the makers, in the first place, fit only two *-in. bolts instead of the usual four. Four-bolt rods can be purchased to.cure the trouble, but this is a somewhat expensive procedure, and a quick way, although perhaps not quite such a satisfactory one, is to re-drill the bearing caps from in. to *-in. and fit good-quality bolts to suit. One vehicle which was altered four years ago has been running ever since without a recurrence of the trouble, although on one oCcasion this vehicle was driven 12 miles, loaded, with a bigend completely run out !--.[Not a risk which it is wise to take.—En.]