CM investigates

Page 62

Page 63

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Roll over Risks

THE Transport industry must never underestimate the unheralded skill with which a majority of drivers go about their daily task. High loads are accepted quite naturally just as being "a bit dodgy", and many drivers handling them never even think about the possibility of "the lot going over-. But I consider that operators should be aware of the hard facts regarding how and why vehicles turn over, and at what frighteningly low speeds this can happen. Those operating driving schools should include practical demonstrations—the only real method of convincing drivers about anything—in their curricula.

At the 1968 Commercial Motor Show, Peak Trailer and and Chassis Co. Ltd, showed for the first time its swinging-arm independent suspension mounted beneath a platform semi-trailer. The unit is based on one similar which Peak has developed very successfully on its caravan trailer chassis, the production of which runs to some hundreds each week. When I spoke about the suspension to Mr. Bill Bowden, director of engineering at Peak, he told me that stability was one of the leading features of the unit, although smooth riding characteristics in both the laden and unladen conditions were among the aims of its designers.

At the latter end of 1968 while I was visiting a tanker-vehicle building company, the risk of tankers turning over at low speeds —thrown up at a conference on maintenance, distribution and containerization (CM Nov 29, R. 33—was among the subjects discussed and it set me thinking about the Peak independent suspension and its makers' claims of stability.

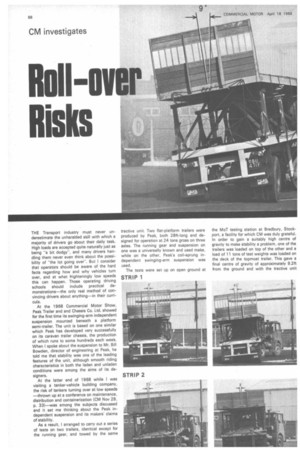

As a result, I arranged to carry out a series of tests on two trailers, identical except for the running gear, and towed by the same tractive unit. Two flat-platform trailers were produced by Peak, both 28ft-long and designed for operation at 24 tons gross on three axles. The running gear and suspension on one was a universally known and used make, while on the other, Peak's coil-sprung independent swinging-arm suspension was used.

The tests were set up on open ground at the MoT testing station at Bredbury, Stockport, a facility for which CM was duly grateful. In order to gain a suitably high centre of gravity to make stability a problem, one of the trailers was loaded on top of the other and a load of 11 tons of test weights was loaded on the deck of the topmost trailer, This gave a final centre of gravity of approximately 9.2f1 from the ground and with the tractive unit for the tests—a Seddon 32 four with Royce Eagle 220bhp engine—brought ital weight of the vehicle to within a few Is of 21 tons.

give myself an indisputable yardstick by I could measure the performance of the endent suspension I first loaded this unit ) of the conventional trailer.

that I would be able to measure the difference in tilt resistance of the two outfits reasonably accurately, a circle 106ft in diameter was laid out. The beam-axled outfit was driven round this, starting at 5 mph and increasing the speed on each circuit by 1 mph until the inside wheel of the semi-trailer parted company with the ground. On the conventional trailer this state was reached when the vehicle was moving at 12 mph, when it was possible to continue circulating with the wheel just clear of the ground. I found that there was sufficient feel in the machine to permit the balance to be retained.

Next, to assess what the pendulum effect of the load would be when the outfit was put through an S-bend, the course was changed to simulate a roundabout with the same radii as the circle on which the first tests were . Whereas on the full circle the trailer )1 lifted at 12 mph, on the second section e S-turns made in negotiating the roundt, the same effect was achieved at only ph, an 8.3 per cent decrease in speed.

le of the highlights of a report made by leers of a petroleum company on artic lity was that acceleration out of a bend, the outfit was still in a partially folded lion, would set up an acute tendency rds overturning. To permit subsequent ;urement of the seriousness of this factor t of all checked the rate of acceleration ble with the outfit in the two gears which I feasibly be used at the speeds the test 'bons permitted. This proved to be: in gear from 0-15 mph, 9,2sec, and 5-15 6.2sec. In fourth gear, from 12-15 mph )m the test made turning a full 106ft I knew that the inside wheel of the i-axle would start to lose contact at 12 so it followed that this was the maximum speed at which the circle could be negotiated. So, bearing in mind the report issued by the oil company engineers. I opted to start my test runs at 1 mph. From this speed I made continuous runs round the circuit I had laid out, increasing the speed each time by 1 mph. At the paint on each circuit where the steering direction had to be changed, full throttle was applied until the outfit approached the wheellifting speed.

When my approach speed had risen to only 4 mph the inside wheel showed daylight between it and the road as soon as the load transfer took effect on accelerating. I continued the exercise until I felt that the outfit could not be safely handled—which in fact occurred at 8 mph approach speed. At this speed the machine staggered and was on the verge of toppling over.

I now had a complete practical picture of the actual stability of the outfit when laden with a moderately high and heavy load. On the road there had been no symptoms that the vehicle would be very easily overturned and as I had already driven it for about 20 miles I felt completely happy about taking it on a substantial journey which I felt could have quite safely been completed.

Now, however, I was in possession of hard facts that proved just how near to disaster many loads—stacked higher and heavier than on the test vehicle—really are. Even under the controlled conditions of the test there were occasions when only the availability of plenty of space permitted the vehicle to be kept on its feet, and present-day traffic conditions do not allow much room for manoeuvre.

The two trailers were now swapped over, the beam-axled unit being loaded on top of the independently sprung vehicle and the 11 tons of test weights on top of that.

Immediately I drove the rejigged outfit I gained the impression that it was considerably more stiff. To find out whether this was due to a harder suspension I took the outfit over a road where on the day previous I had watched the semi-trailer—in the driving mirror—pitching all over the place while some loose equipment that was carried on the lower platform bounced about on the floorboards. The independent suspension unit rode over this section at the same speed with none of the attendant roughness. After completing my 20-mile circuit of road evaluation I then returned to the MoT Bredbury to complete the second leg of the trial.

Using exactly the same technique as on the previous day. I circulated round and round the 106ft circle until the road speed reached 16 mph, 4 mph faster than was possible with the beam-axled unit. But, with absolutely no warning at this speed the inner trailer-wheel suddenly lifted a foot off the ground and I had a few sticky moments re-landing it. So I knew that this was a point to be watched and I restarted circulating at 14 mph, completing some 12 to 15 circuits to get the feel of the lifting point. Try as I might I could not achieve the degree of control that had been possible with the beam axle, but I had to bear in mind that the speed at which breakaway occurred was 25 per cent higher.

I now decided that I must find another way of checking whether stability up to the breakaway point was indeed as good as it felt, so I decided to move the load over to one side of the trailer (the outside of the circle) and try again. I then set off again on the circles to see what happened. In fact nothing changed: the outfit appeared to handle exactly the same and the inner wheel lifted at exactly the same speed—becoming equally uncontrollable once it did so.

From these exercises I came to the conclusion that the independent was indeed considerably more stable up to a speed 33+ per cent greater than the beam axle, so for good measure I decided to leave the load imposed on the outside of the body and see what happened during the S-turns and accelerations out of a bend.

During the S-turns on my simulated roundabout I had to raise the approach speed of the outfit to 15 mph—an increase of 37 per cent before the inner wheel broke away from the road surface. And I found it significant that the outfit travelled about 35ft further round the second bend before the lift-off occurred. The acceleration tests also proved that the inner wheel lifted at a considerably higher road speed than had been the case with the beam axle.

Whereas that unit had lifted at 4 mph and became unhandleable at 8 mph, the independent suspension lifted at 8 mph and became very unstable at 16 mph—exactly 100 per cent better.

My conclusions are that, in a given set of circumstances, this form of independent suspension is definitely more stable than a conventional beam-axle unit. It will resist all but the most outrageous efforts to turn it over, while at the same time affording a considerably kinder ride to delicate cargoes and /or bodywork. One must not overlook the fact that after the first set of full circles was completed during the test of the independent, a considerable penalty in the form of an offset load was then imposed for the whole of the remainder of the exercise. And, of course, that all the tests were undertaken with a load that any driver worth his salt would recognize as -dodgy".