An Austin Change-speed Gear

Page 74

If you've noticed an error in this article please click here to report it so we can fix it.

A Résumé of Recently Published Patent Specifications

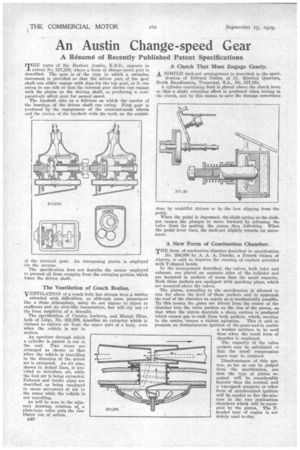

THE name of Sir Herbert Austin, K.B.E., appears in Patent No. 317,230, where a form of change-speed gear is described. The gear is of the type in which a swinging movement is provided so that the driven part of the gear shaft can either engage with dogs for the top gear, or it can swing to one side so that the internal gear shown can engage with the pinion on the driving shaft, so producing a coniparatively silent gear for second speed.

The layshaft acts as a fulcrum on which the carrier of the bearings of the driven shaft can swing. First gear is produced by the engagement of the constant-mesh wheels and the pinion of the layshaft with the teeth on the outside of the internal gear. An interposing pinion is employed for the reverse.

The specification does not describe the means employed to prevent oil from escaping from the swinging portion which bears the driven shaft.

The Ventilation of Coach Bodies.

VENTILATION of a coach body has always been a matter

attended with difficulties, as although some passengers like a clean atmosphere, many do not appear to object to stuffiness and an oven-like temperature, but will cry out tt the least suspicion of a draught.

The specification of Carolus Ledercq, and Marcel Elias, both of Liege, No. 301,376, describes an extractor which is claimed to extract air from the upper part of a body, even when the vehicle is not in motion.

An aperture through which a cylinder is passed is cut in the roof. Two cones are arranged as shown so that when the vehicle is travelling in the direction of the arrow air is extracted. An air pipe, shown in dotted lines, is provided to introduce air, while the foul air is being extracted. Exhaust and intake pipes are described as being employed to cause movement of air in the cones while the vehicle is not travelling.

As will be seen in the adjacent drawing, rotation of„. a plate-type valve puts the ventilator out of action.

3340

A Clutch That Must Engage Gently.

A SIMPLE dash-pot arrangement is described in the specification of Edward Dollar, of 31, Married Quarters, North Randfontein, Transvaal, S.A., No. 317,181.

A cylinder containing fluid is placed above the clutch lever so that a slight retarding effect is produced when letting in the clutch, and by this means to save the damage sometimes done by unskilful drivers or by the foot slipping from the pedal.

When the pedal is depressed, the slight spring on the dashpot causes the plunger to move forward by releasing the valve from its seating, the piston then following. When the pedal lever rises, the dash-pot slightly retards its movement.

A New Form of Combustion Chamber.

THE form of combustion chamber described in specification No. 294,886 by A. A. A. Darche, a French citizen of Algiers, is said to improve the running of engines provided with T-shaped heads.

In the arrangement described, the valves, both inlet and exhaust, are placed on opposite sides of the cylinder and are mounted in pockets of more. than the usual capacity. Both these pockets are equipped with sparking plugs, which are mounted above the valves.

The piston, according to the specification is allowed to rise far above the level of these pockets and to approach the roof of the chamber as nearly as is mechanically possible. By this means the gases are driven from the centre of the chamber into the valve pockets on the rise of the piston, so that when the piston descends a sharp suction is produced which causes gas to rush from both pockets, which, meeting

in the centre,'canses a violent agitation. This is said to promote an instantaneous ignition of the gases and to enable a weaker mixture to be used than when the usual form of chamber is employed.

The capacity of the valve pockets may be calculated ro that the usual compression space may be retained.

Disadvantages of this system, so far as can be judged from the specification, are that the type of piston required will be considerably heavier than the normal, and a two-spark magneto or other form of synchronized ignition will be needed to Ere the mixture in the two combustion chambers which will be separated by the piston. The Theaded type of engine is not widely used to-day.